Nissan Sentra. Manual - part 397

EC-284

< DTC/CIRCUIT DIAGNOSIS >

[MRA8DE]

P0420 THREE WAY CATALYST FUNCTION

11. Rev engine up to 2,000 to 3,000 rpm and hold it for 3 consecutive minutes then release the accelerator

pedal completely.

12. Check the indication of “CATALYST”.

Which is displayed on CONSULT screen?

CMPLT >> GO TO 5.

INCMP >> GO TO 3.

3.

PERFORM DTC CONFIRMATION PROCEDURE-2

1. Wait 5 seconds at idle.

2. Rev engine up to 2,000 to 3,000 rpm and maintain it until “INCMP” of “CATALYST” changes to “CMPLT” (It

will take approximately 5 minutes).

Does the indication change to “CMPLT”?

YES

>> GO TO 5.

NO

>> GO TO 4.

4.

PERFORM DTC CONFIRMATION PROCEDURE AGAIN

1. Stop engine and cool it down to less than 70

°C (158°F).

2. Perform DTC confirmation procedure again.

>> GO TO 2.

5.

PERFORM DTC CONFIRMATION PROCEDURE-3

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Proceed to

.

NO

>> INSPECTION END

6.

PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to

EC-284, "Component Function Check"

NOTE:

Use component function check to check the overall function of the three way catalyst (manifold). During this

check, a 1st trip DTC might not be confirmed.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Proceed to

.

Component Function Check

INFOID:0000000009758531

1.

PERFORM COMPONENT FUNCTION CHECK

Without CONSULT

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Restart engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no

load.

4. Let engine idle for 1 minute.

5. Open engine hood.

6. Check the voltage between ECM harness connector terminals as per the following condition.

Is the inspection result normal?

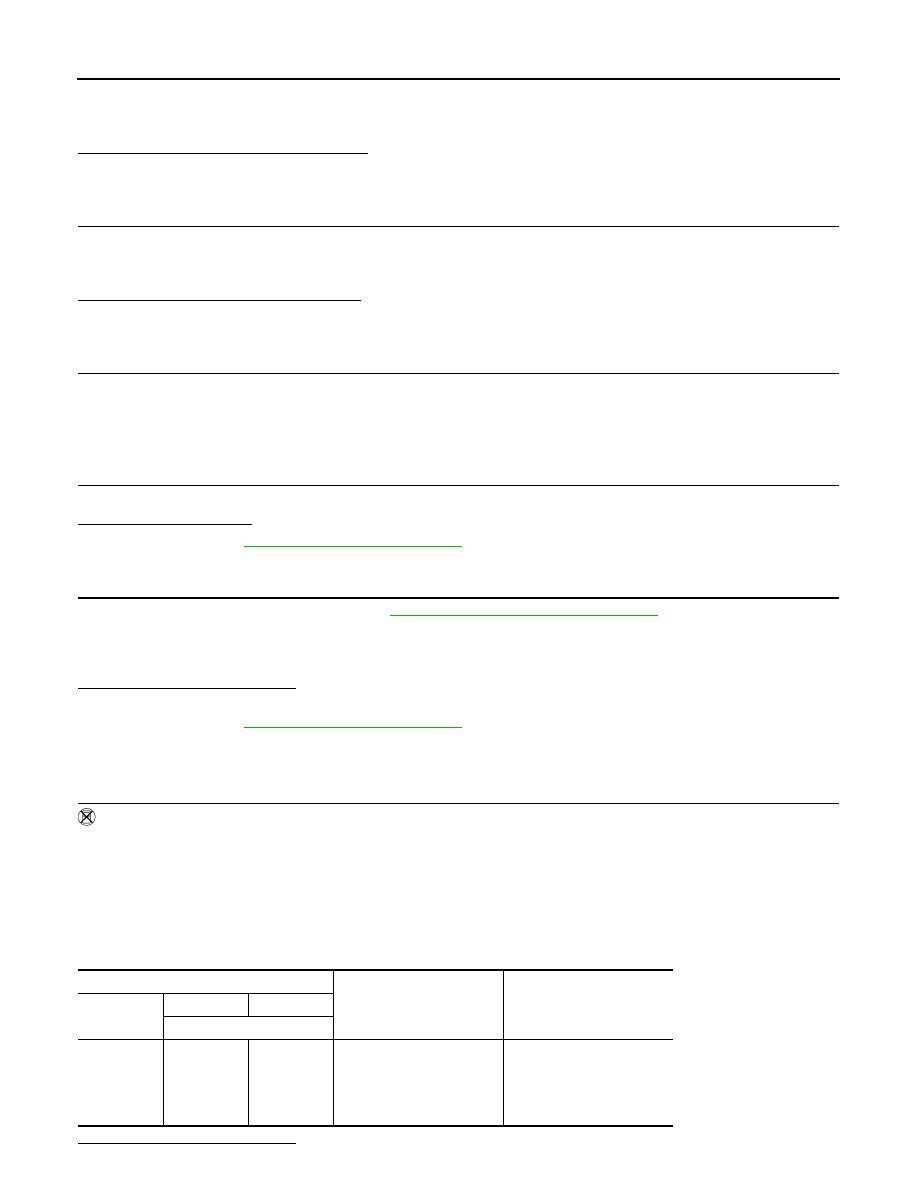

ECM

Condition

Voltage (V)

Connector

+

–

Terminal

F24

22

23

Keeping engine speed at

2500 rpm constant under no

load

The voltage fluctuation cy-

cle takes more than 5 sec-

onds.

• 1 cycle: 0.6 - 1.0

→ 0 - 0.3

→ 0.6 - 1.0