Nissan Leaf. Manual - part 941

MA-22

< PERIODIC MAINTENANCE >

EV SYSTEM MAINTENANCE

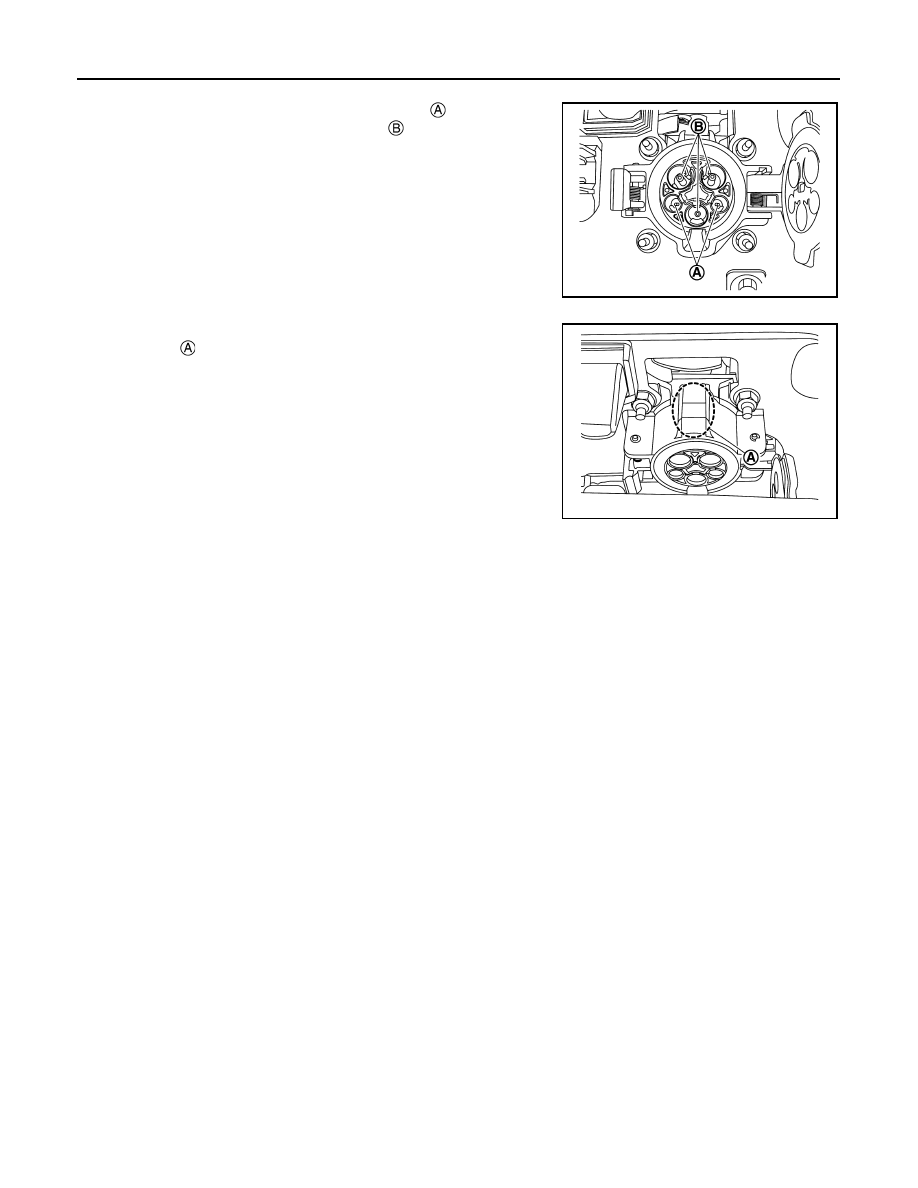

• Malfunction in opening/closing the charge port caps and looseness when closed and locked.

• Check that the normal charge port terminals are not bent.

• Check that the contact prevention cap is not missing.

NOTE:

If it is missing, it is extremely difficult to engage the charge

connector.

• Check that there is no snow or ice on the normal charge port

top side .

NOTE:

If snow or ice reaches the charge connector lock, charging

does not start.

Handling of charge port

Cleaning of charge port

If the charge port becomes dirty, clean the port with an air blow gun.

Handling of damaged cap

Perform the following procedure if the cap becomes damaged:

• Replace charge port cap if the charge port cap becomes damaged

• Replace charge port if the packing of quick charge port becomes cracked.

• Replace charge port if the terminal of quick charge port or normal charge port becomes damaged.

Cleaning of the inside of rubber cap

If air does not exit through the rubber cap hole, remove the rubber cap from the port and clean the inside so

that air exits through the rubber cap hole.

JPCIA0369ZZ

JPCIA0370ZZ