Nissan Leaf. Manual - part 940

MA-18

< PERIODIC MAINTENANCE >

EV SYSTEM MAINTENANCE

EV SYSTEM MAINTENANCE

COOLANT

COOLANT : Inspection

INFOID:0000000010121525

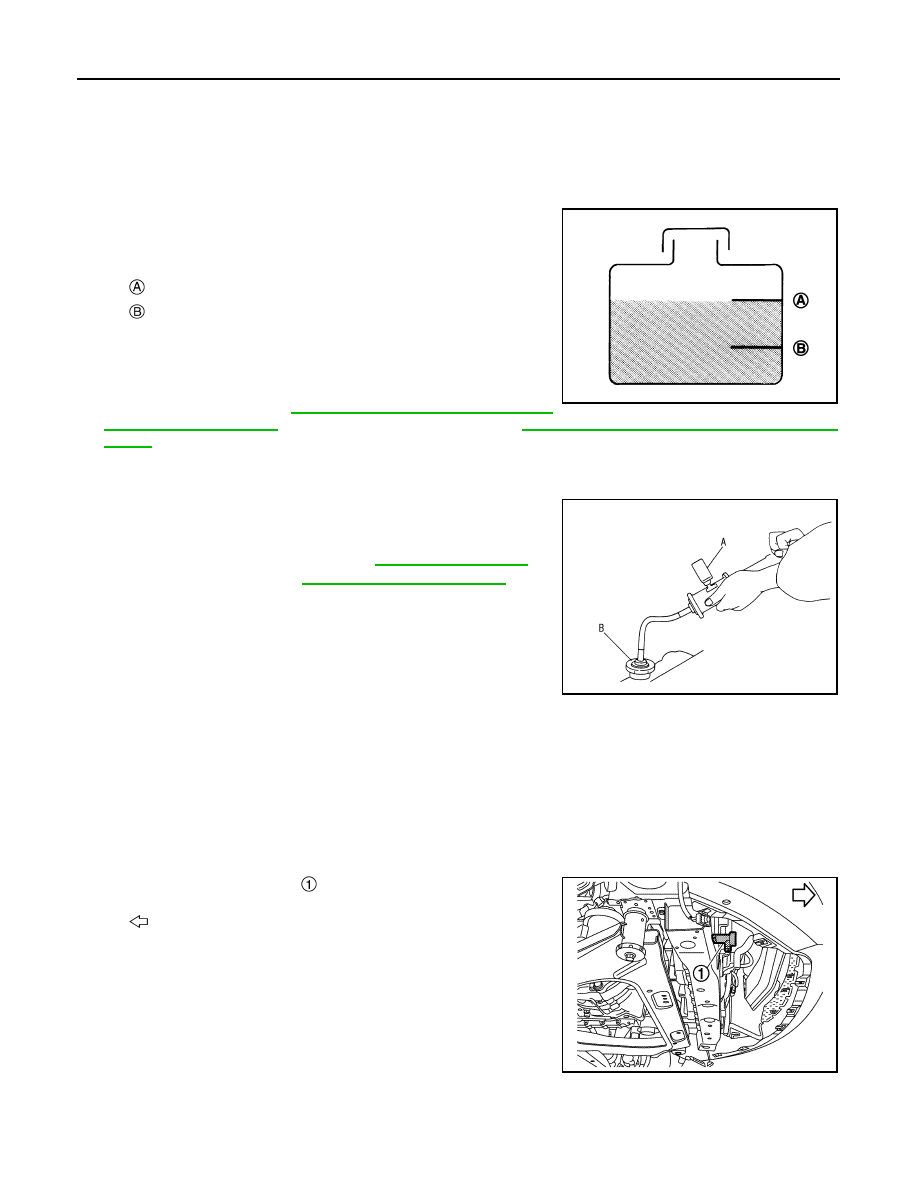

COOLANT AMOUNT INSPECTION

• When coolant temperature is low (about 50

°C or less), confirm that

the coolant level of the reservoir tank is in the range from MIN to

MAX.

• Adjust level if it is outside the range.

CAUTION:

• Refill Genuine NISSAN Long Life Antifreeze/Coolant (blue)

or equivalent in its quality mixed with water (distilled or

demineralized). Refer to

(United States and Canada) or

MA-17, "FOR MEXICO : Fluids and Lubri-

• Confirm that the reservoir tank cap is tightened.

LEAKAGE CHECK

• Apply pressure to the cooling system using radiator cap tester (A)

(commercial service tool). Check system for coolant leakage.

CAUTION:

• Remove the degas tank cap when coolant temperature is

low.

• Perform the inspection with the radiator filled with water.

• Use hose adapter (B) (commercial service tool) between

radiator cap tester (A) (commercial service tool) and the

filler neck so that the degas tank filler neck is not deformed.

• Be sure to observe the maximum pressure standards. Otherwise, radiator may be damaged.

• If there is a malfunction, repair and replace applicable part.

COOLANT : Draining

INFOID:0000000010121526

CAUTION:

• Be sure to drain when coolant temperature is cold.

• This should be performed so that coolant does not come in contact with surrounding parts.

1. Remove Li-ion battery undercover.

2. Remove radiator drain plug , and drain coolant.

3. Remove reservoir tank and drain the coolant as per the following procedure.

1. Remove radiator upper grille cover.

2. Remove water hose (reservoir tank side) and reservoir tank mounting bolts.

: MAX

: MIN

JPBIA0102ZZ

Maximum pressure

: Refer to

.

PBIC5121J

: Vehicle front

JPCIA0342ZZ