Nissan Leaf. Manual - part 747

HA-110

< REMOVAL AND INSTALLATION >

[WITHOUT HEAT PUMP SYSTEM]

CONDENSER

LIQUID TANK : Removal and Installation

INFOID:0000000010122179

DANGER:

Since hybrid vehicles and electric vehicles contain a high voltage battery, there is the risk of

electric shock, electric leakage, or similar accidents if the high voltage component and vehicle are

handled incorrectly. Be sure to follow the correct work procedures when performing inspection and

maintenance.

WARNING:

• Be sure to remove the service plug in order to disconnect the high voltage circuits before perform-

ing inspection or maintenance of high voltage system harnesses and parts.

• The removed service plug must always be carried in a pocket of the responsible worker or placed in

the tool box during the procedure to prevent the plug from being connected by mistake.

• Be sure to wear insulating protective equipment consisting of glove, shoes, face shield and glasses

before beginning work on the high voltage system.

• Never allow workers other than the responsible person to touch the vehicle containing high voltage

parts. To keep others from touching the high voltage parts, these parts must be covered with an insu-

lating sheet except when using them. Refer to

GI-34, "High Voltage Precautions"

CAUTION:

Never bring the vehicle into the READY status with the service plug removed unless otherwise

instructed in the Service Manual. A malfunction may occur if this is not observed.

REMOVAL

1. Use the refrigerant recovery equipment (for HFC134a) and recover the refrigerant. Refer to

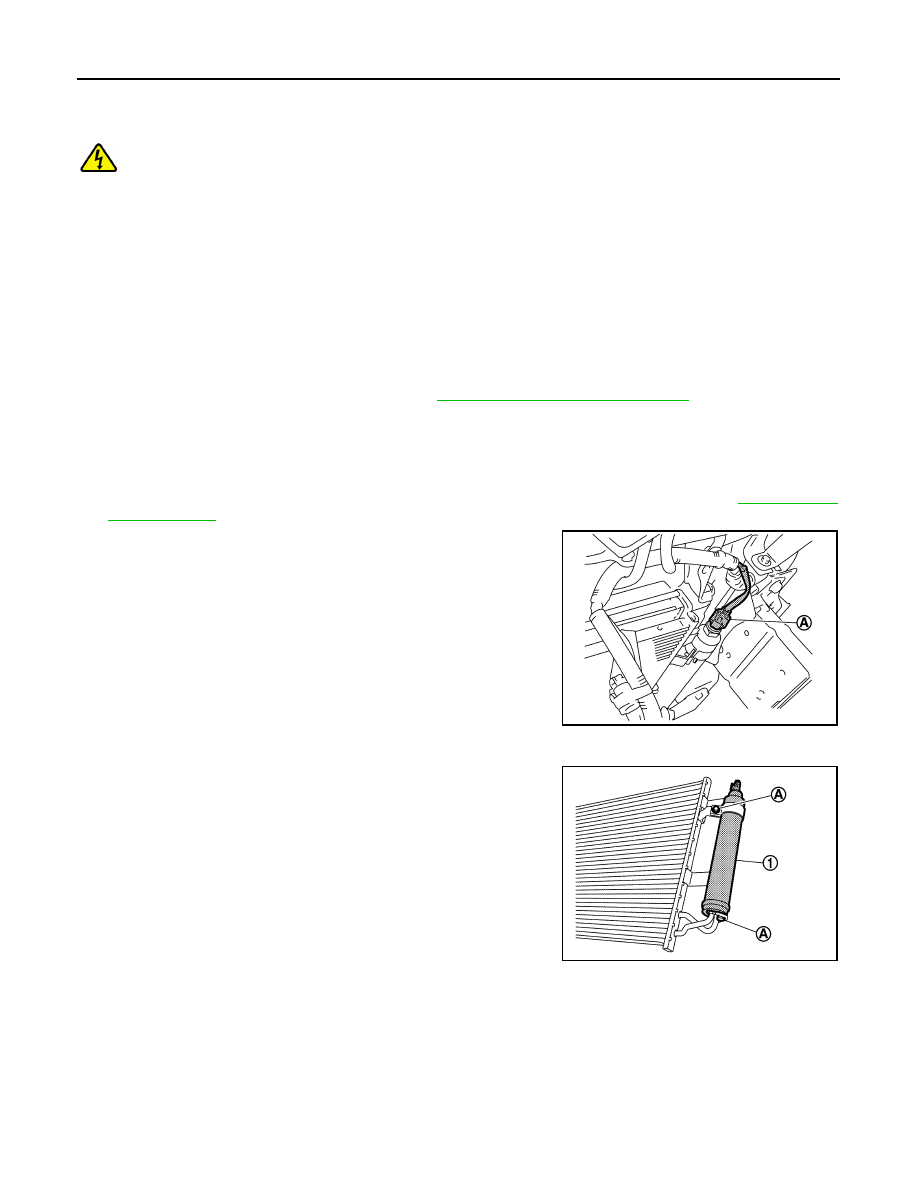

2. Disconnect refrigerant pressure sensor connector (A).

3. Clean around the liquid tank to remove any dirt or corrosion.

4. Remove bolts (A), and then remove liquid tank (1) from con-

denser.

CAUTION:

To prevent the inclusion of foreign matter, use a cap or vinyl

tape to seal off the connection ports of the liquid tank and

condenser from the atmosphere.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

• To prevent degradation in insulation performance, use special electric compressor oil as the com-

pressor oil.

• In order to prevent conventional PAG oil from becoming mixed in, never reuse recovered compres-

sor oil and instead always use new oil. The use of oil including the conventional PAG oil may

degrade the performance of insulation.

JPIIA1775ZZ

JPIIA1777ZZ