Nissan Leaf. Manual - part 685

FRONT DRIVE SHAFT

FAX-21

< REMOVAL AND INSTALLATION >

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

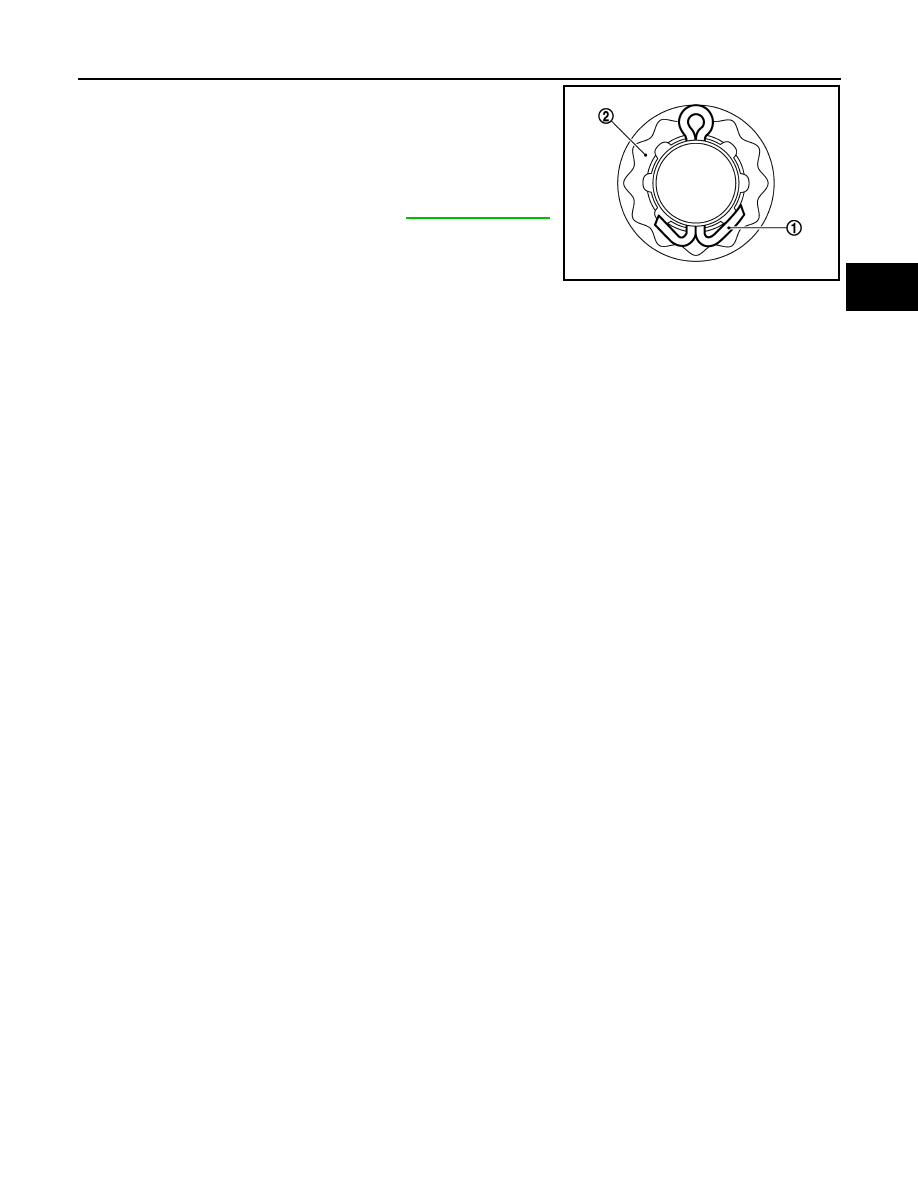

• When installing a cotter pin (1) and nut retainer (2), securely bend

the basal portion to prevent rattles.

CAUTION:

Do not reuse cotter pin.

• Perform the final tightening of each of parts under unladen condi-

tions, which were removed when removing wheel hub assembly

and steering knuckle.

• Perform inspection after installation. Refer to

JPDIF0295ZZ