Nissan Frontier D22. Manual - part 935

WT-4

WHEEL

WHEEL

PFP:40300

Inspection

EES000XS

1.

Check tires for wear and improper inflation.

2.

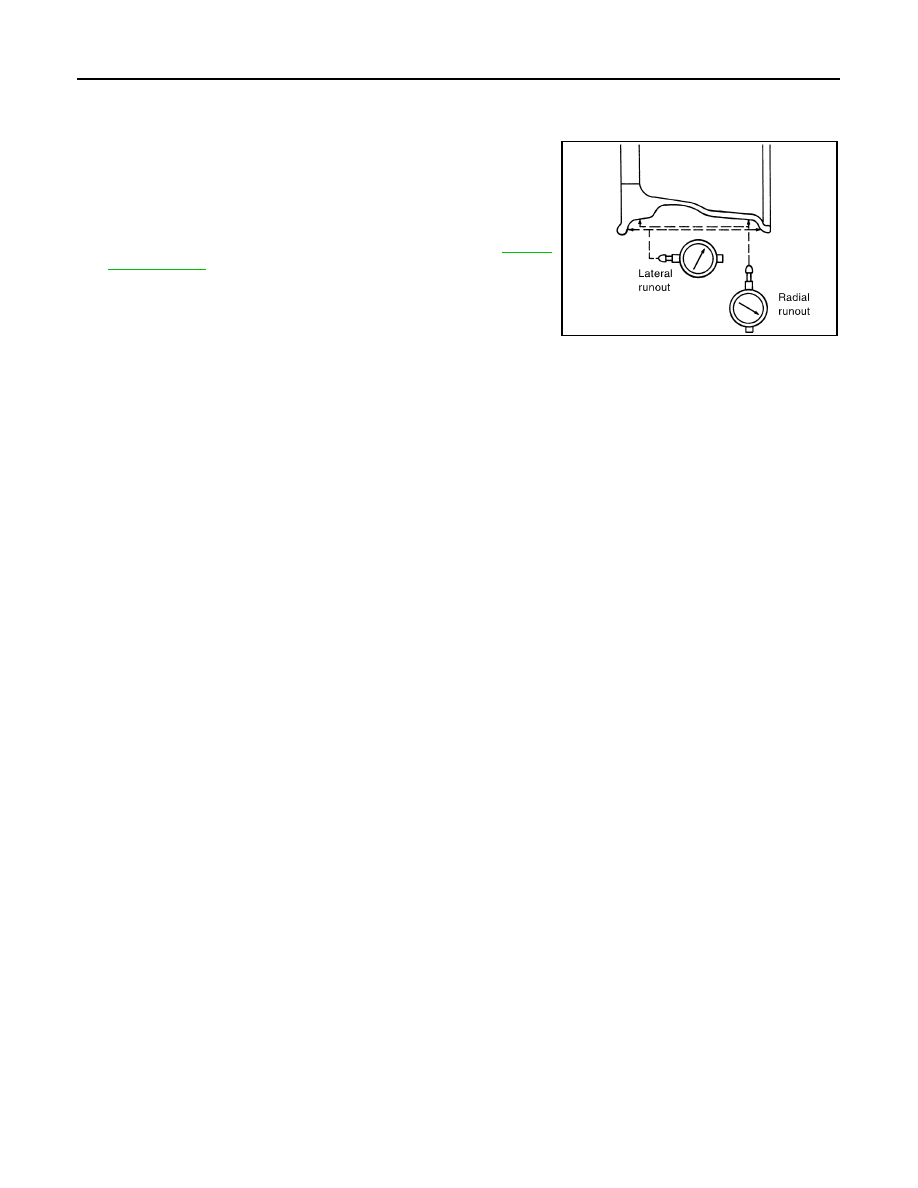

Check wheels for deformation, cracks and other damage. If

deformed, remove wheel and check wheel runout.

a.

Remove tire from wheel and mount wheel on a tire balance

machine.

b.

Set dial indicator as shown in the illustration. Refer to

3.

Check front wheel bearings for looseness.

4.

Check front suspension for looseness.

SFA975B