Nissan Frontier D22. Manual - part 838

MTC-74

REFRIGERANT LINES

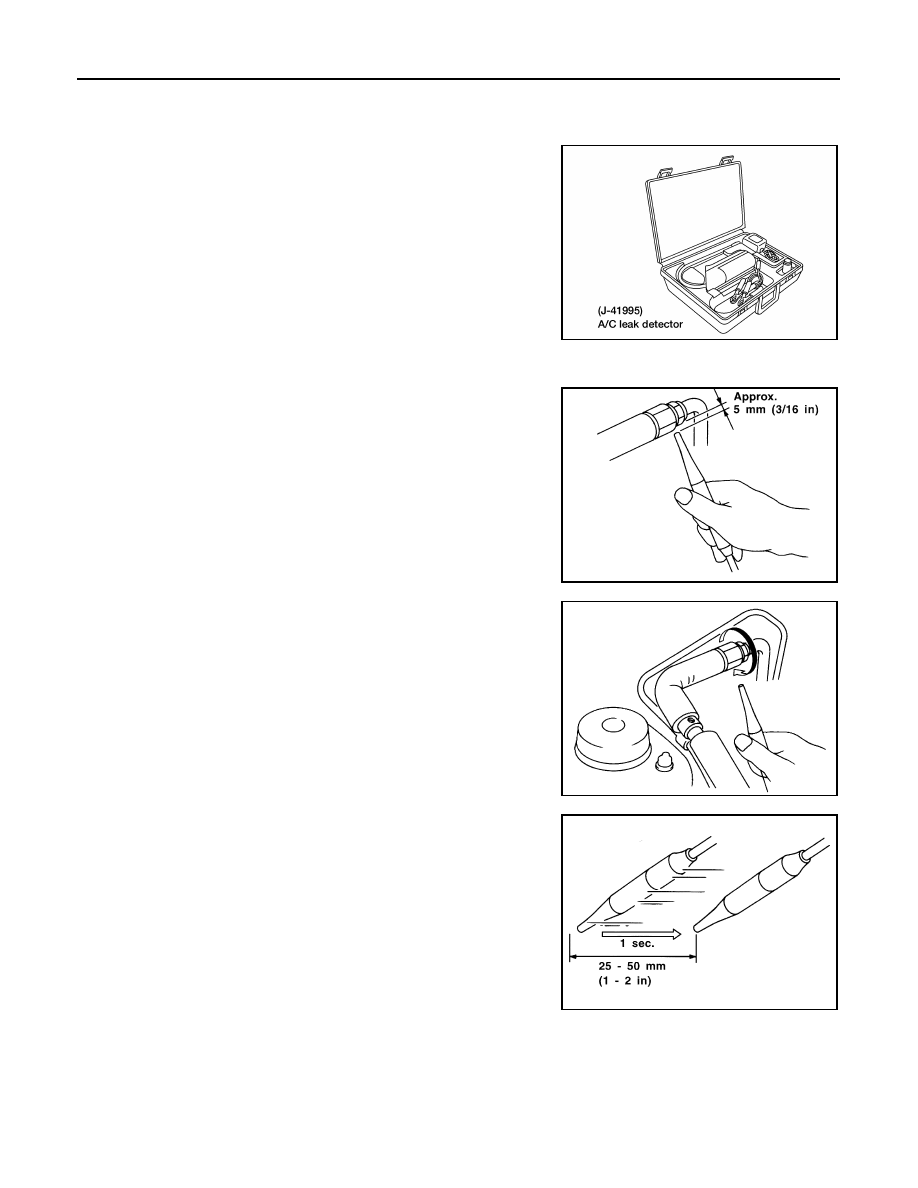

Electronic Refrigerant Leak Detector

EJS0020S

PRECAUTIONS FOR HANDLING LEAK DETECTOR

NOTE:

●

When performing a refrigerant leak check, use a J-41995 A/C

leak detector or equivalent. Ensure that the instrument is cali-

brated and set properly per the operating instructions.

●

The leak detector is a delicate device. In order to use the leak

detector properly, read the operating instructions and perform

any specified maintenance.

●

Other gases in the work area or substances on the A/C compo-

nents, for example, anti-freeze, windshield washer fluid, sol-

vents and lubricants, may falsely trigger the leak detector. Make

sure the surfaces to be checked are clean. Clean with a dry

cloth or blow off with shop air.

●

Do not allow the sensor tip of the detector to contact any sub-

stance. This can also cause false readings and may damage the detector.

1.

Position probe approximately 5 mm (3/16 in) away from point to

be checked.

2.

When testing, circle each fitting completely with probe.

3.

Move probe along component approximately 25 - 50 mm (1 - 2

in)/sec.

CHECKING PROCEDURE

NOTE:

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals or smoke in

the vicinity of the vehicle. Perform the leak test in a calm area (low air/wind movement) so that the leaking

refrigerant is not dispersed.

1.

Turn engine off.

AHA535A

SHA707EA

SHA706E

SHA708EA