Nissan Frontier D22. Manual - part 819

MT-82

[FS5R30A]

SERVICE DATA AND SPECIFICATIONS (SDS)

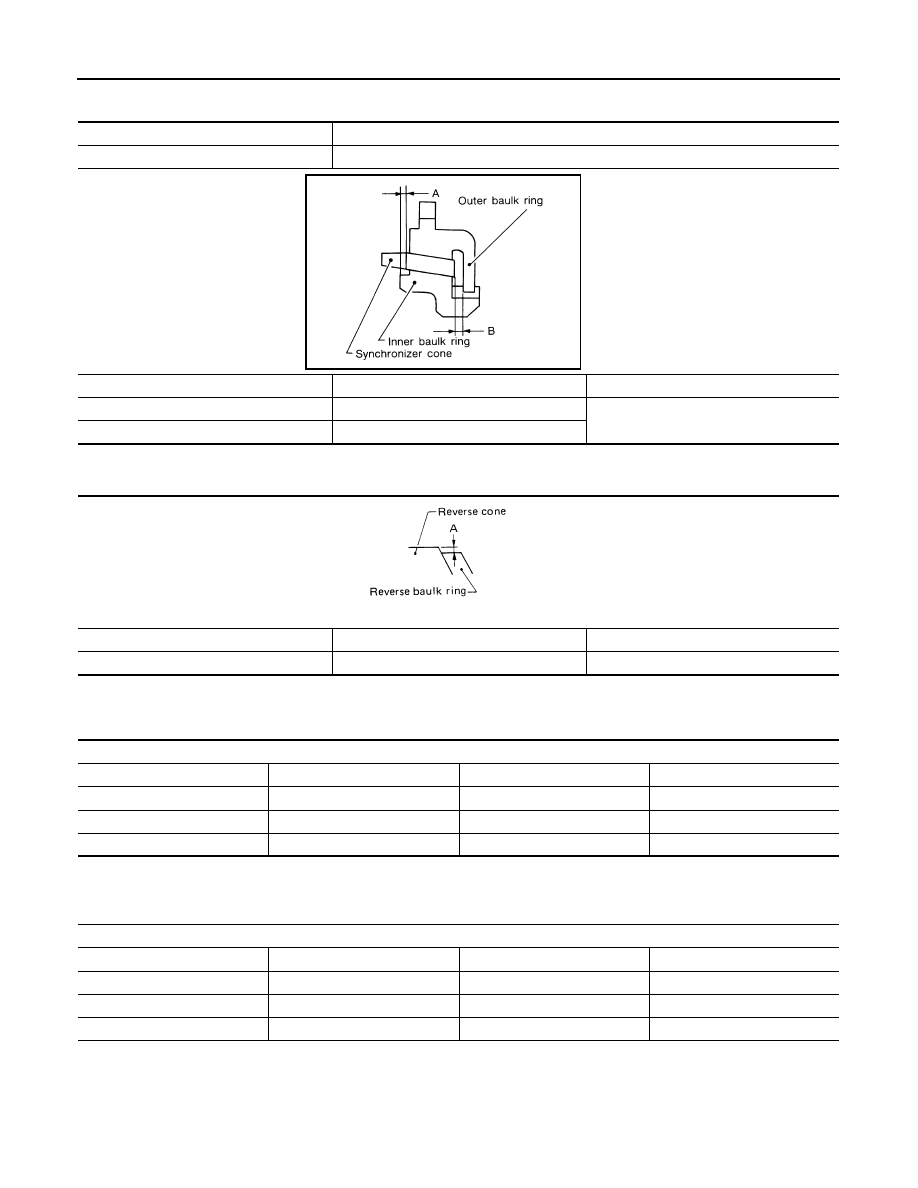

DOUBLE BAULK RING

Unit: mm (in)

Distance Between Rear Surface of Reverse Cone and Reverse Baulk Ring

ECS007ID

Unit: mm (in)

Available Snap Ring

ECS007IE

MAIN DRIVE GEAR SNAP RING

Unit: mm (in)

*Always check with the Parts Department for the latest parts information.

MAINSHAFT FRONT BEARING SNAP RING

Unit: mm (in)

*Always check with the Parts Department for the latest parts information.

VG33E model

2nd & 3rd baulk rings

VG33ER model

1st, 2nd & 3rd baulk rings

Dimension

Standard

Wear limit

A

0.7 - 0.9 (0.028 - 0.035)

0.2 (0.008)

B

0.6 - 1.1 (0.024 - 0.043)

SMT742C

Dimension

Standard

Wear limit

A

0.35 to 0.95 (0.0119 to 0.0295)

1.1 (0.043)

SMT428C

Main drive gear snap ring groove allowable clearance

0 - 0.1 (0 - 0.003)

Thickness

Part number*

Thickness

Part number*

1.89 (0.0744)

32204-01G60

2.03 (0.0799)

32204-01G63

1.95 (0.0768)

32204-01G61

2.07 (0.0815)

32204-01G64

1.99 (0.0783)

32204-01G62

2.11 (0.0831)

32204-01G65

Mainshaft front bearing snap ring groove allowable clearance

0 - 0.1 (0 - 0.003)

Thickness

Part number*

Thickness

Part number*

1.99 (0.0783)

32204-01G62

2.11 (0.0831)

32204-01G65

2.03 (0.0799)

32204-01G63

2.15 (0.0846)

32204-01G66

2.07 (0.0815)

32204-01G64

2.19 (0.0862)

32204-01G67