Nissan Frontier D22. Manual - part 735

ON-VEHICLE SERVICE

FSU-15

C

D

F

G

H

I

J

K

L

M

A

B

FSU

3.

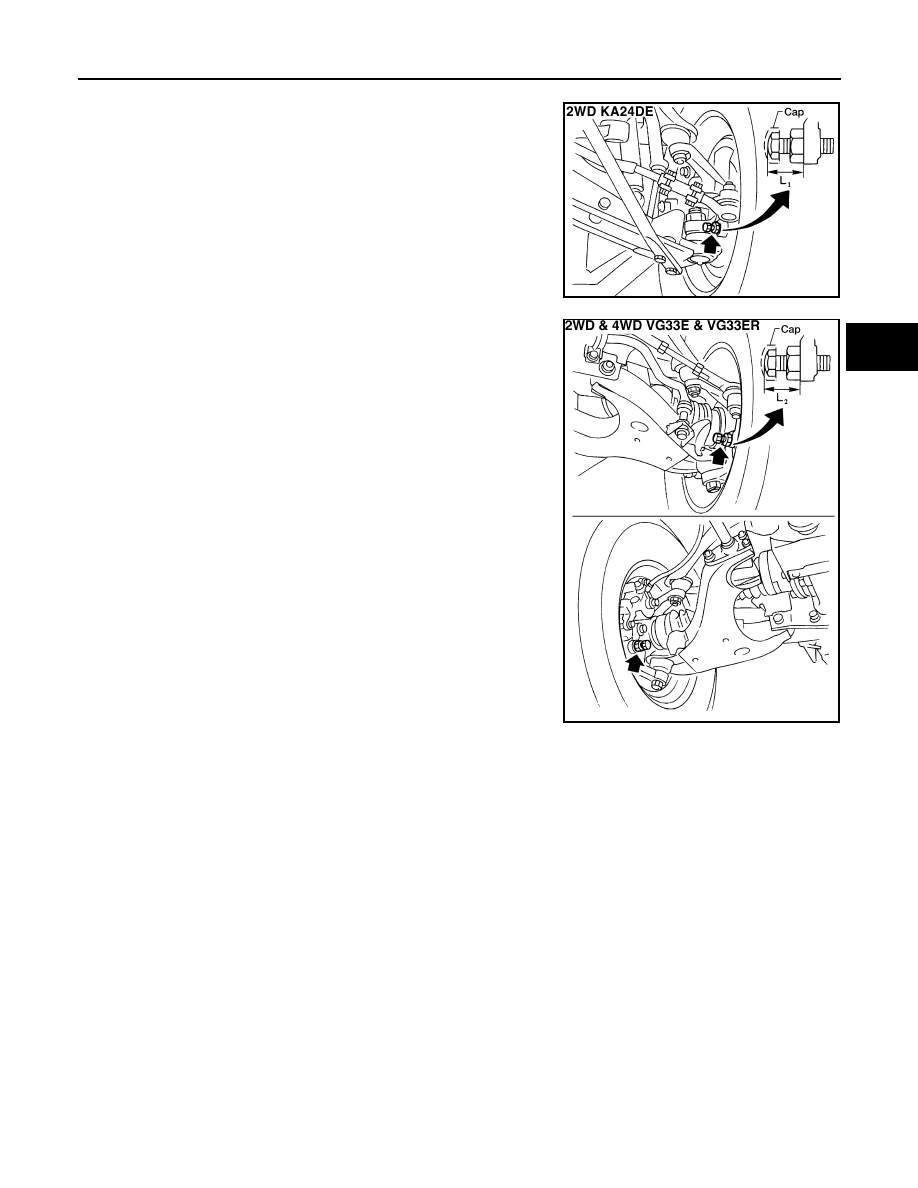

Adjust stopper bolt if necessary.

Standard length “L

1

”

(2WD KA24DE model)

: 26.5 mm (1.043 in)

(Length before cap is

mounted)

ASU045

Standard length “L

2

”

(2WD and 4WD VG33E

and VG33ER models)

: Except P265/70R15 tire

26.5 mm (1.043 in)

(Length before cap is

mounted)

: P265/70R15 tire

30.0 mm (1.2 in)

(Length before cap is

mounted)

WSU019