Nissan Frontier D22. Manual - part 528

BASIC SERVICE PROCEDURE

EC-1215

[VG33ER]

C

D

E

F

G

H

I

J

K

L

M

A

EC

18.

PREPARATION FOR CO% CHECK

With CONSULT-II

1.

Select “ENG COOLANT TEMP” in “ACTIVE TEST” mode.

2.

Set “ENG COOLANT TEMP” to 5

°C (41°F) by touching “DWN”

and “Qd”.

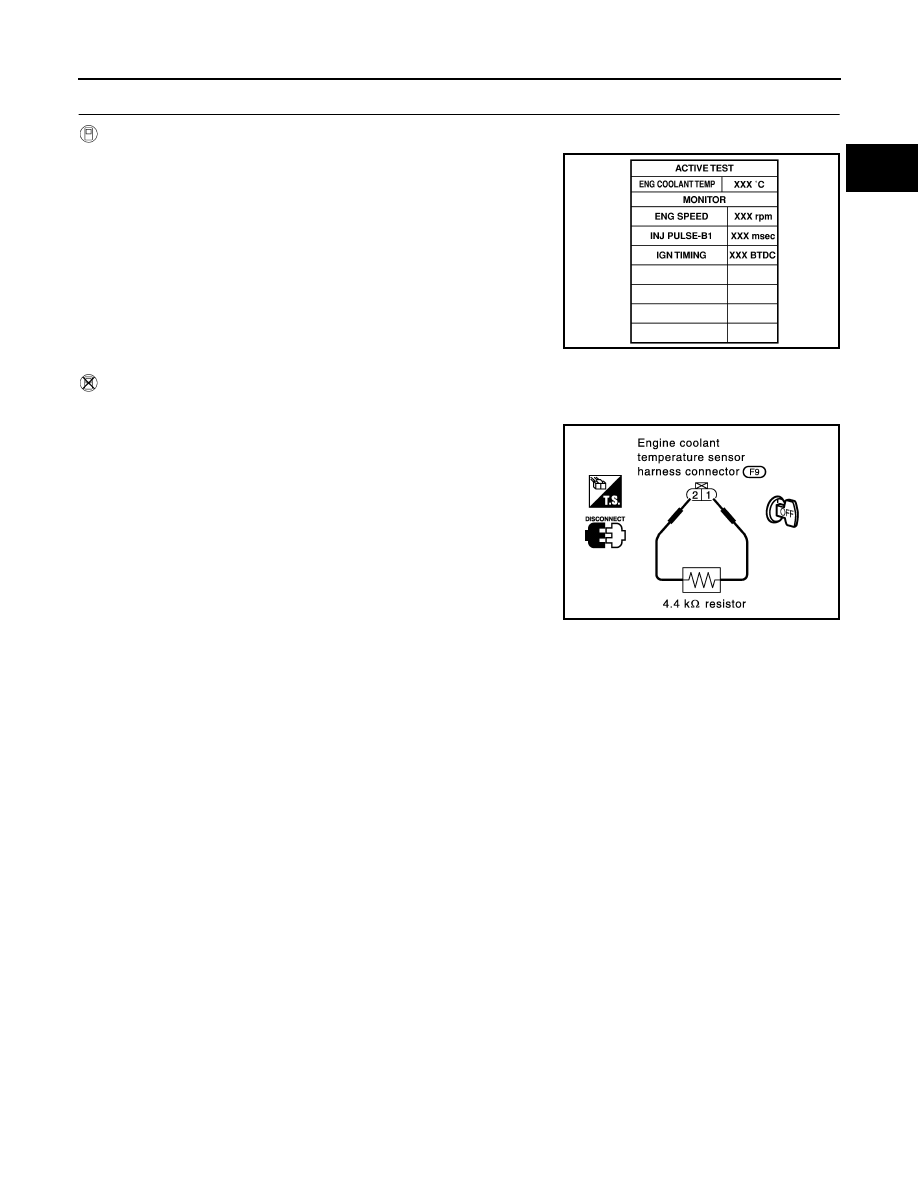

Without CONSULT-II

1.

Disconnect engine coolant temperature sensor harness connector.

2.

Connect a resistor (4.4 k

Ω) between terminals of engine coolant

temperature sensor harness connector.

>> GO TO 19.

SEF172Y

PBIB1436E