Nissan Frontier D22. Manual - part 527

BASIC SERVICE PROCEDURE

EC-1211

[VG33ER]

C

D

E

F

G

H

I

J

K

L

M

A

EC

10.

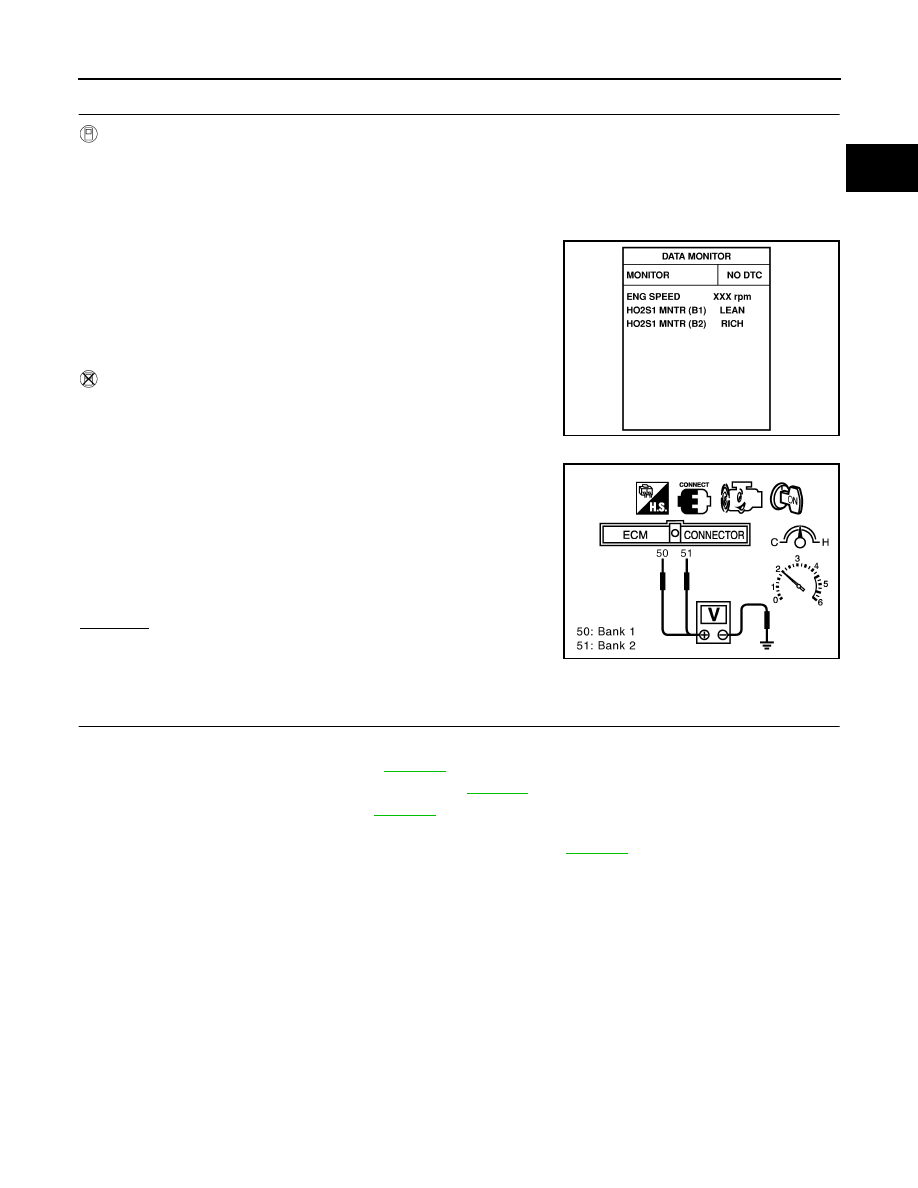

CHECK HEATED OXYGEN SENSOR 1 (BANK 2) SIGNAL

With CONSULT-II

1.

Stop engine.

2.

Replace heated oxygen sensor 1 (bank 2).

3.

Start engine and warm it up to normal operating temperature.

4.

Run engine at approx. 2,000 rpm for approx. 2 minutes under no load.

5.

See “HO2S1 MNTR (B2)” in “DATA MONITOR” mode.

6.

Running engine at 2,000 rpm under no load (engine is warmed

up to normal operating temperature.), check that the monitor

fluctuates between “LEAN” and “RICH” more than 5 times dur-

ing 10 seconds.

1 time: RICH

→ LEAN → RICH

2 times: RICH

→ LEAN → RICH → LEAN → RICH

Without CONSULT-II

1.

Stop engine.

2.

Replace heated oxygen sensor 1 (bank 2).

3.

Start engine and warm it up to normal operating temperature.

4.

Run engine at approx. 2,000 rpm for approx. 2 minutes under no

load.

5.

Set voltmeter probe between ECM terminal 51 and ground.

6.

Make sure that the voltage fluctuates between 0 - 0.3V and 0.6 -

1.0V more than 5 times during 10 seconds at 2,000 rpm.

1 time: 0 - 0.3V

→ 0.6 - 1.0V → 0 - 0.3V

2 times: 0 - 0.3V

→ 0.6 - 1.0V → 0 - 0.3V → 0.6 - 1.0V → 0 -

0.3V

OK or NG

OK (With CONSULT-II)>>GO TO 12.

OK (Without CONSULT-II)>>GO TO 13.

NG

>> GO TO 11.

11.

DETECT MALFUNCTIONING PART

Check the following.

1.

Check fuel pressure regulator. Refer to

2.

Check mass air flow sensor and its circuit. Refer to

.

3.

Check injector and its circuit. Refer to

Clean or replace if necessary.

4.

Check engine coolant temperature sensor and its circuit. Refer to

5.

Check ECM function by substituting another known-good ECM.

(ECM may be the cause of an incident, but this is a rare case.)

>> GO TO 2.

PBIB0120E

PBIB2157E