Nissan Frontier D22. Manual - part 356

DTC P1775 TCC SOLENOID VALVE

EC-527

[KA24DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

3.

CHECK OUTPUT SIGNAL CIRCUIT

1.

Turn ignition switch “OFF”.

2.

Disconnect ECM harness connector.

3.

Check voltage between ECM terminal 115 and TCC solenoid valve terminal 3.

Refer to Wiring Diagram.

4.

Also check harness for short to ground or short to power.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 4.

4.

DETECT MALFUNCTIONING PART

Check the following.

●

Harness connectors E43, M65

●

Harness connectors M81, F36

●

Harness for open and short between torque converter clutch solenoid valve and ECM

>> Repair open circuit, short to ground or short to power in harness or connectors.

5.

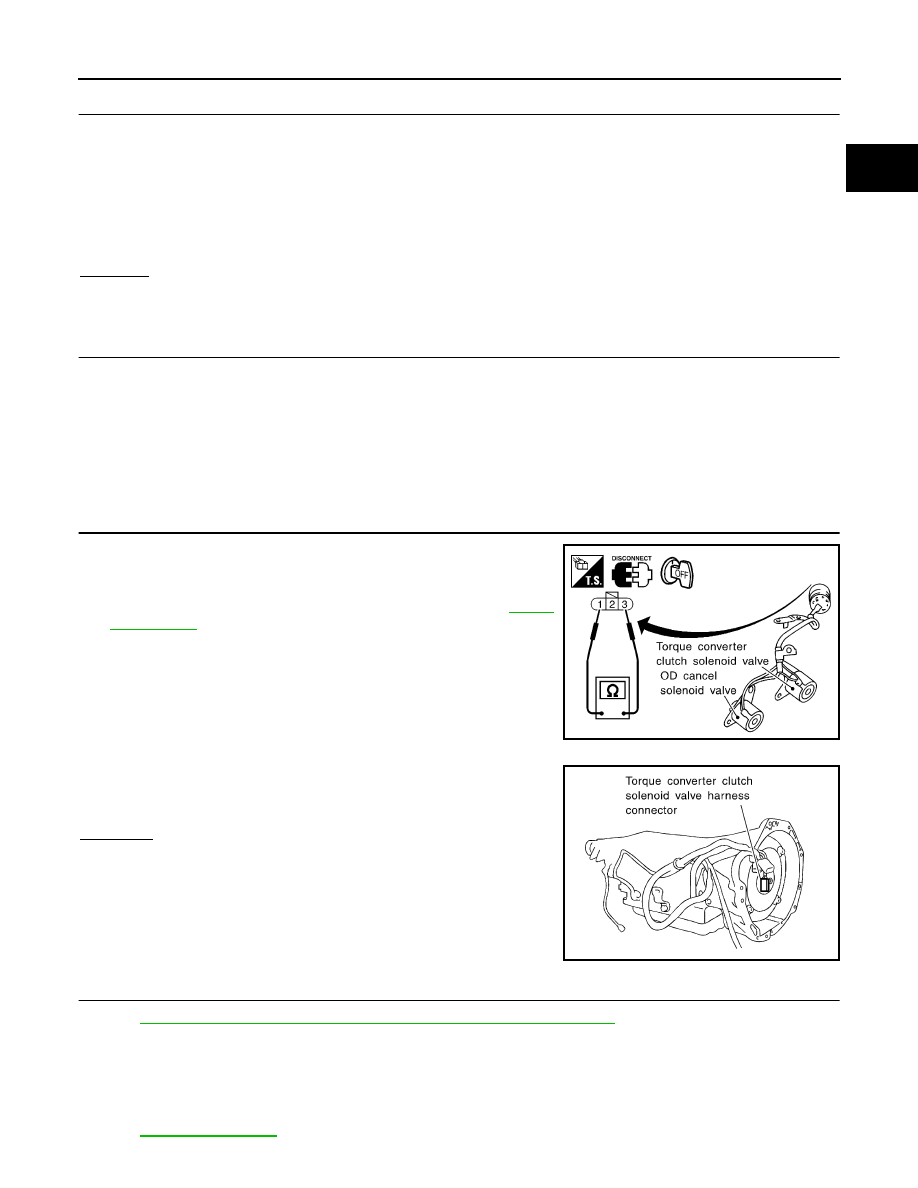

CHECK TORQUE CONVERTER CLUTCH SOLENOID VALVE

1.

Check resistance between torque converter clutch solenoid

valve terminals 1 and 3.

Resistance: Approximately 25

Ω [at 25°C (77°F)]

2.

Remove torque converter clutch solenoid valve. Refer to

3.

Supply the solenoid valve terminals 1 and 3 with battery voltage

and check the solenoid valve operation.

Torque converter clutch solenoid valve should be operated.

OK or NG

OK

>> GO TO 6.

NG

>> Replace torque converter clutch solenoid valve.

6.

CHECK INTERMITTENT INCIDENT

Perform

EC-120, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT"

>> INSPECTION END.

Removal and Installation

UBS00DCS

TORQUE CONVERTER CLUTCH SOLENOID VALVE

Refer to

.

Continuity should exist.

SEF233V

SEF507V