Nissan Frontier D22. Manual - part 189

TROUBLE DIAGNOSIS

BRC-87

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

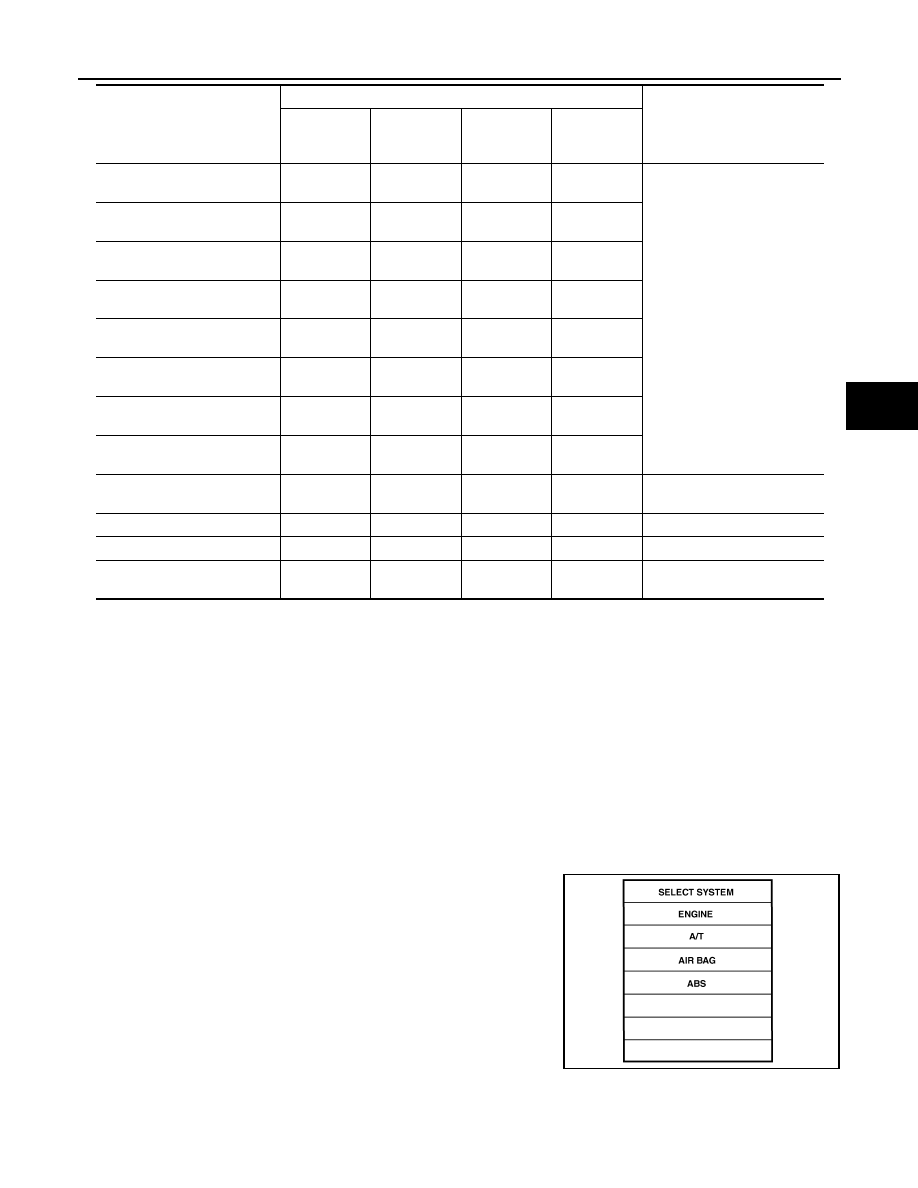

×:Applicable

–:Not applicable

ACTIVE TEST

Operation Procedure

CAUTION:

●

Do not perform active test while driving the vehicle.

●

Make sure to completely bleed air from brake system.

●

Active test cannot be performed when ABS warning lamp is on.

1.

Connect the CONSULT-II connector to the data link connector and start the engine.

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

2.

Touch

″START″ on the display.

3.

Touch

″ABS″ and ″ACTIVE TEST″.

CAN CIRC 1

(OK/UNKWN)

–

–

–

×

CAN communication signal

(OK/UNKWN) status is dis-

played.

CAN CIRC 2

(OK/UNKWN)

–

–

–

×

CAN CIRC 3

(OK/UNKWN)

–

–

–

×

CAN CIRC 4

(OK/UNKWN)

–

–

–

×

CAN CIRC 5

(OK/UNKWN)

–

–

–

×

CAN CIRC 6

(OK/UNKWN)

–

–

–

×

CAN CIRC 7

(OK/UNKWN)

–

–

–

×

CAN CIRC CLC

(OK/UNKWN)

–

–

–

×

TRQ MAP S/C

–

–

×

–

S/C is selected for engine

torque map

TRQ MAP N/A

–

–

×

–

N/A is selected for engine

2WD/4WD SEL

–

–

×

–

Distinguish 2WD and 4WD

CLC VOLT

(V)

–

–

×

–

Voltage supplied to CAN-LAN

converter is displayed

Item

(Unit)

Data monitor item selection

Remarks

ECU INPUT

SIGNALS

MAIN

SIGNALS

SELECTION

FROM

MENU

CAN DIAG

SUPPORT

MNTR

WBR110