Nissan Xterra. Manual - part 490

PRECAUTIONS

LU-3

< PRECAUTION >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

LU

N

P

O

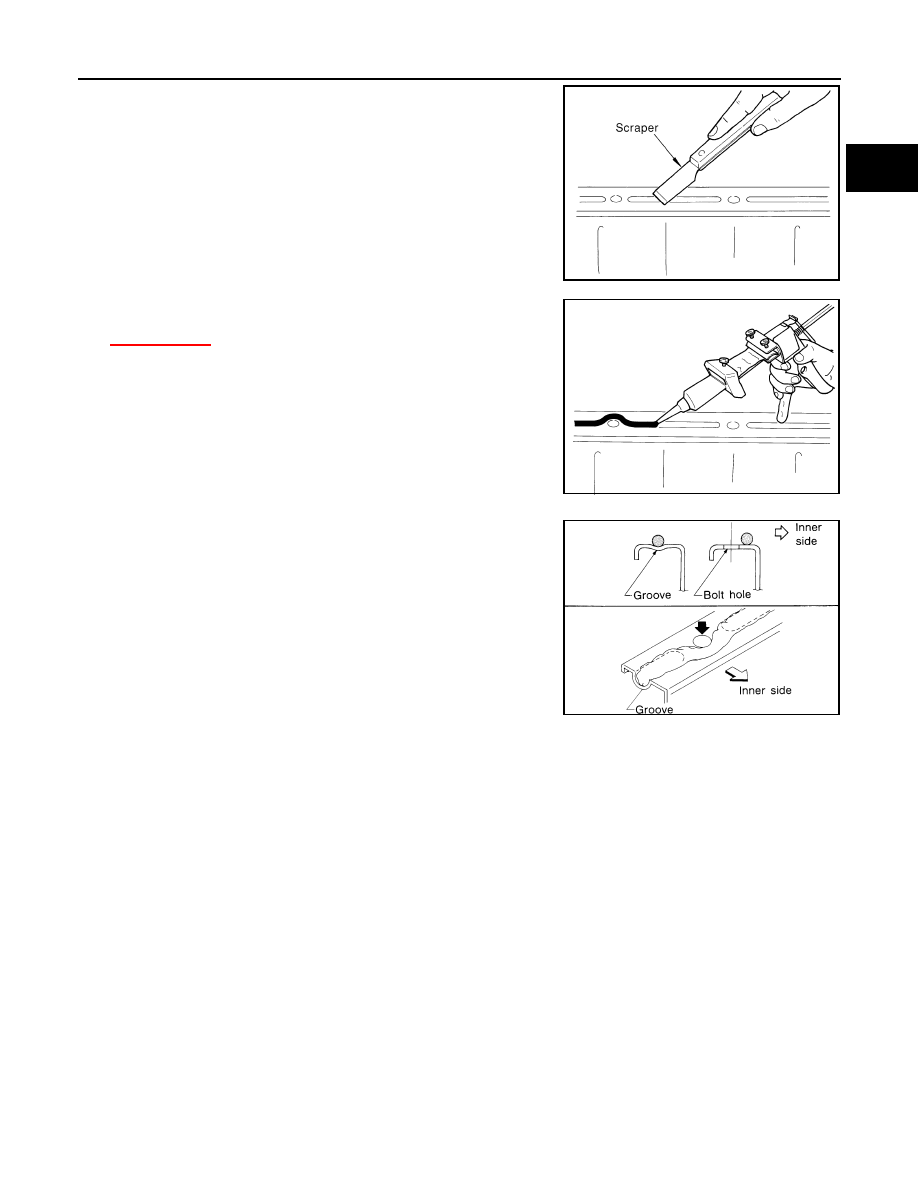

1. Remove the old liquid gasket adhering to the gasket application

surface and the mating surface using suitable tool.

• Remove the liquid gasket completely from the groove of the

liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering

moisture, grease and foreign material.

3. Attach the liquid gasket tube to the suitable tool.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

XX-XX, "*****"

.

4. Apply the liquid gasket without breaks to the specified location

with the specified dimensions.

• If there is a groove for the liquid gasket application, apply the

liquid gasket to the groove.

• Normally apply the liquid gasket on the inside edge of the bolt

holes. Also apply to the outside edge of the bolt holes when

specified in the procedure.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If the liquid gasket protrudes, wipe it off immediately.

• Do not retighten after the installation.

• Wait 30 minutes or more after installation before refilling the

engine with oil or coolant.

CAUTION:

If there are more specific instructions in the procedures contained in this manual concerning liq-

uid gasket application, observe them.

PBIC0003E

EMA0622D

SEM159F