Nissan Xterra. Manual - part 298

EC-318

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE]

P0451 EVAP CONTROL SYSTEM PRESSURE SENSOR

2. Loosen and retighten three ground screws on the body. Refer to

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace ground connections.

2.

CHECK EVPA CONTROL SYSTEM PRESSURE SENSOR CONNECTOR FOR WATER

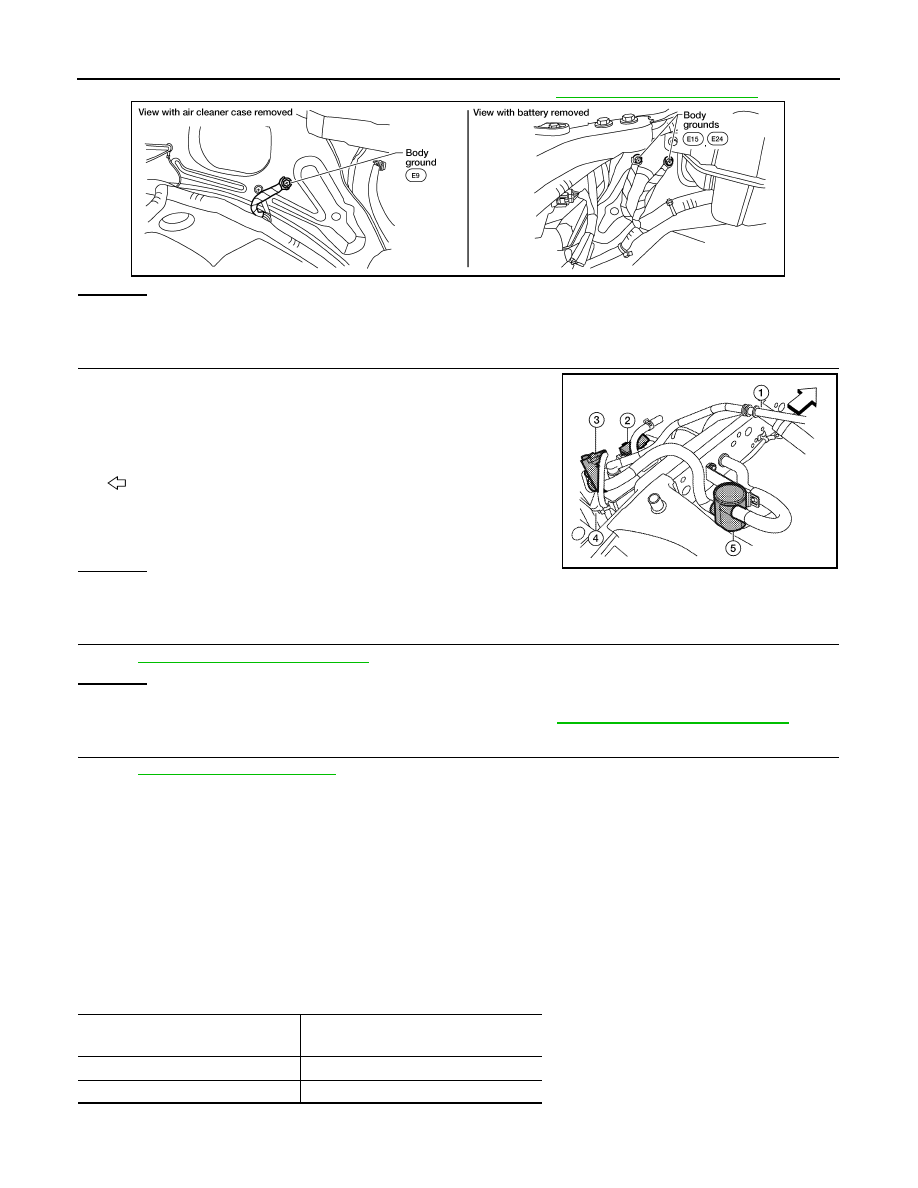

1. Disconnect EVAP control system pressure sensor (2) harness

connector.

-

Fuel filler pipe (1)

-

EVAP canister vent control valve (3)

-

EVAP canister (4)

-

Drain filter (5)

-

: Vehicle front

2. Check sensor harness connector for water.

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace harness connector.

3.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-318, "Component Inspection"

OK or NG

OK

>> GO TO 4.

NG

>> Replace EVAP control system pressure sensor. Refer to

FL-16, "Removal and Installation"

.

4.

CHECK INTERMITTENT INCIDENT

GI-40, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000009484024

EVAP CONTROL SYSTEM PRESSURE SENSOR

1. Remove EVAP control system pressure sensor with its harness connector.

Do not reuse the O-ring, replace it with a new one.

2. Install a vacuum pump to EVAP control system pressure sensor.

3. Turn ignition switch ON and check output voltage between ECM terminal 102 and ground under the fol-

lowing conditions.

CAUTION:

• Always calibrate the vacuum pump gauge when using it.

BBIA0539E

Water should not exist.

AWBIA0223ZZ

Applied vacuum kPa

(kg/cm

2

psi)

Voltage V

Not applied

1.8 - 4.8

-26.7 (-0.272, -3.87)

2.1 to 2.5V lower than above value