Nissan Xterra. Manual - part 296

EC-310

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE]

P0447 EVAP CANISTER VENT CONTROL VALVE

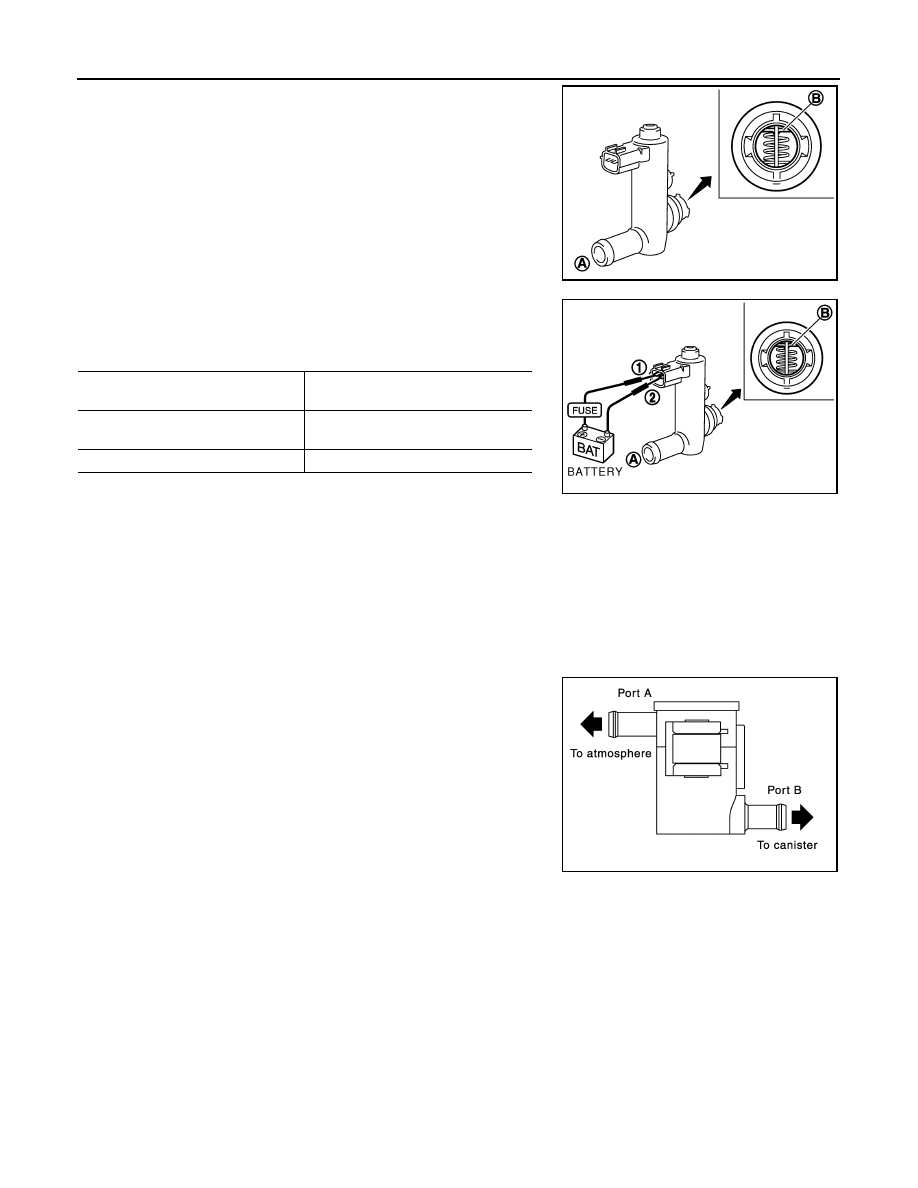

2. Check portion B of EVAP canister vent control valve for being

rusted.

3. Check air passage continuity and operation delay time under the

following conditions.

Make sure that new O-ring is installed properly.

Operation takes less than 1 second.

If NG, go to next step.

4. Clean the air passage (portion A to B) of EVAP canister vent control valve using an air blower.

5. Perform step 3 again.

6. If NG, replace EVAP canister vent control valve.

DRAIN FILTER

1. Check visually for insect nests in the drain filter air inlet.

2. Check visually for cracks or flaws in the appearance.

3. Check visually for cracks or flaws in the hose.

4. Blow air into port A and check that it flows freely out of port B.

5. Block port B.

6. Blow air into port A and check that there is no leakage.

7. If NG, replace drain filter.

PBIB1033E

Condition

Air passage continuity

between (A) and (B)

12V direct current supply between

terminals 1 and 2

No

OFF

Yes

PBIB1034E

PBIB3641E