Nissan March K13. Manual - part 653

TRANSAXLE ASSEMBLY

TM-29

< UNIT DISASSEMBLY AND ASSEMBLY >

[5MT: RS5F91R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

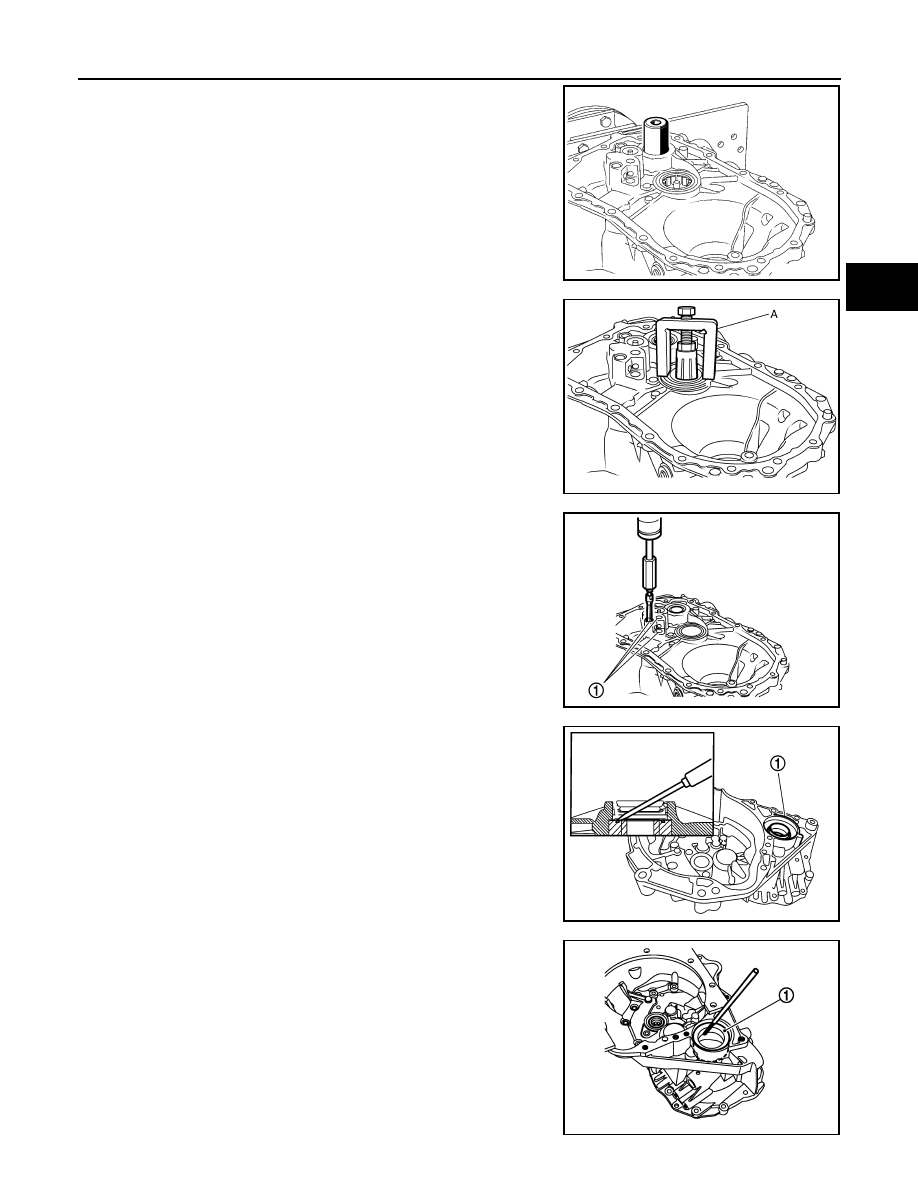

27. Remove input shaft front bearing from clutch housing, using a

drift [Commercial service tool].

28. Cut oil channel tube at the root.

29. Remove mainshaft front bearing and oil channel from clutch

housing, using the valve seat remover (A) [SST: KV111011S0].

30. Remove bushings (1) from clutch housing, using a bearing

remover [Commercial service tool].

31. Remove differential side oil seals (1) from clutch housing and

transaxle case, using a screwdriver.

CAUTION:

Never damage transaxle case and clutch housing.

32. Remove differential side bearing outer races (1) from clutch

housing and transaxle case, using a brass rod.

CAUTION:

Never damage transaxle case and clutch housing.

MCIB0044E

PCIB1536E

PCIB1537E

PCIB1534E

JPDIC0484ZZ