Nissan March K13. Manual - part 542

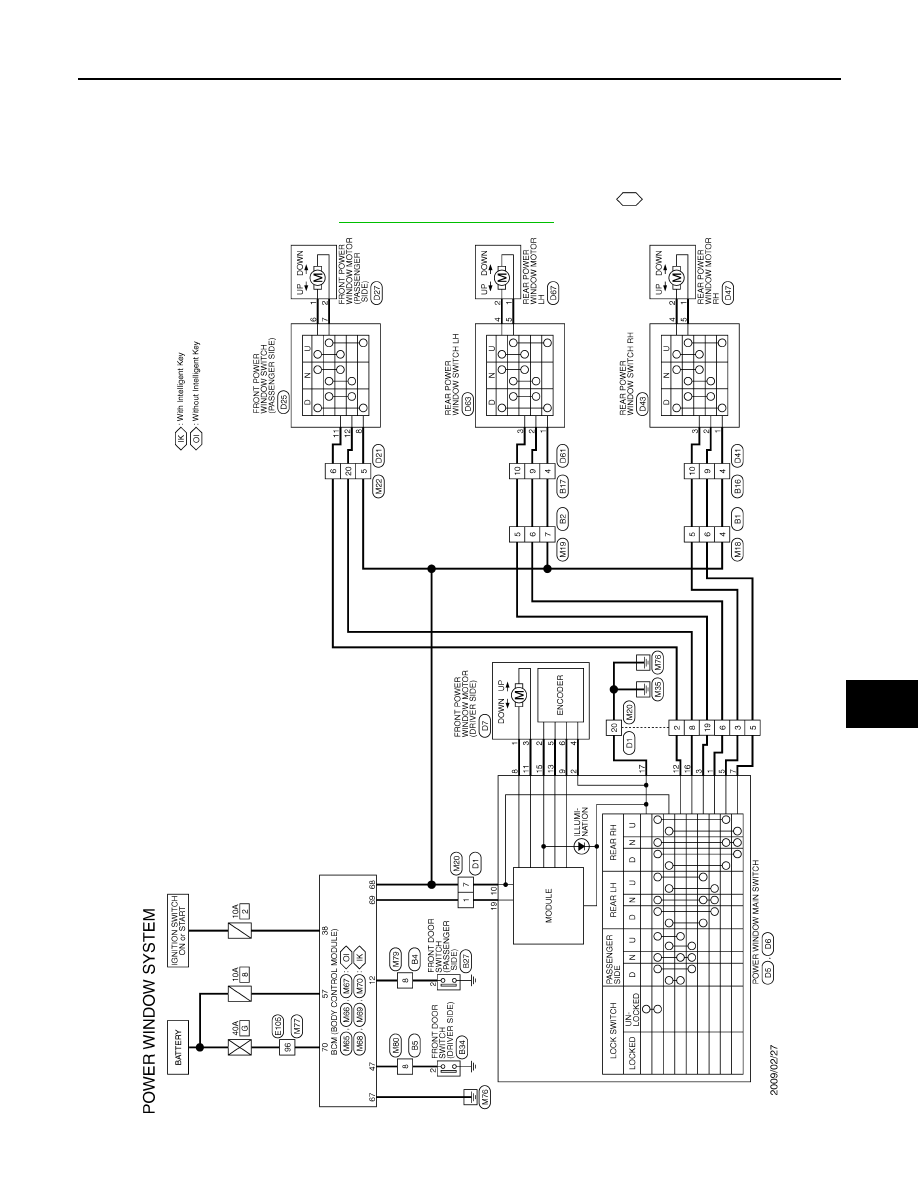

POWER WINDOW SYSTEM

PWC-11

< WIRING DIAGRAM >

C

D

E

F

G

H

I

J

L

M

A

B

PWC

N

O

P

WIRING DIAGRAM

POWER WINDOW SYSTEM

Wiring Diagram

INFOID:0000000005978548

For connector terminal arrangements, harness layouts, and alphabets in a

(option abbreviation; if not

described in wiring diagram), refer to

GI-12, "Connector Information"

JCKWM2861GB