Nissan March K13. Manual - part 328

FRONT WHEEL HUB AND KNUCKLE

FAX-11

< REMOVAL AND INSTALLATION >

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

3.

Install wheel hub, using the drift (SST) and the drift (SST).

Inspection

INFOID:0000000006044463

INSPECTION AFTER REMOVAL

Check the following items, and replace the part if necessary.

• Check components for deformation, cracks, and other damage.

• Check boots of transverse link and steering outer socket ball joint for breakage, axial end play, and swing

torque. Refer to

XX-XX, "*****"

and

XX-XX, "*****"

.

INSPECTION AFTER DISASSEMBLY

Wheel Hub

• Check wheel hub for cracks (with magnetic exploration or dye testing). Replace if necessary.

Steering Knuckle

• Check steering knuckle for deformation, cracks, and other damage. Replace if any non-standard conditions

are found.

Snap Rings

• Check snap ring for wear or cracks. Replace if necessary.

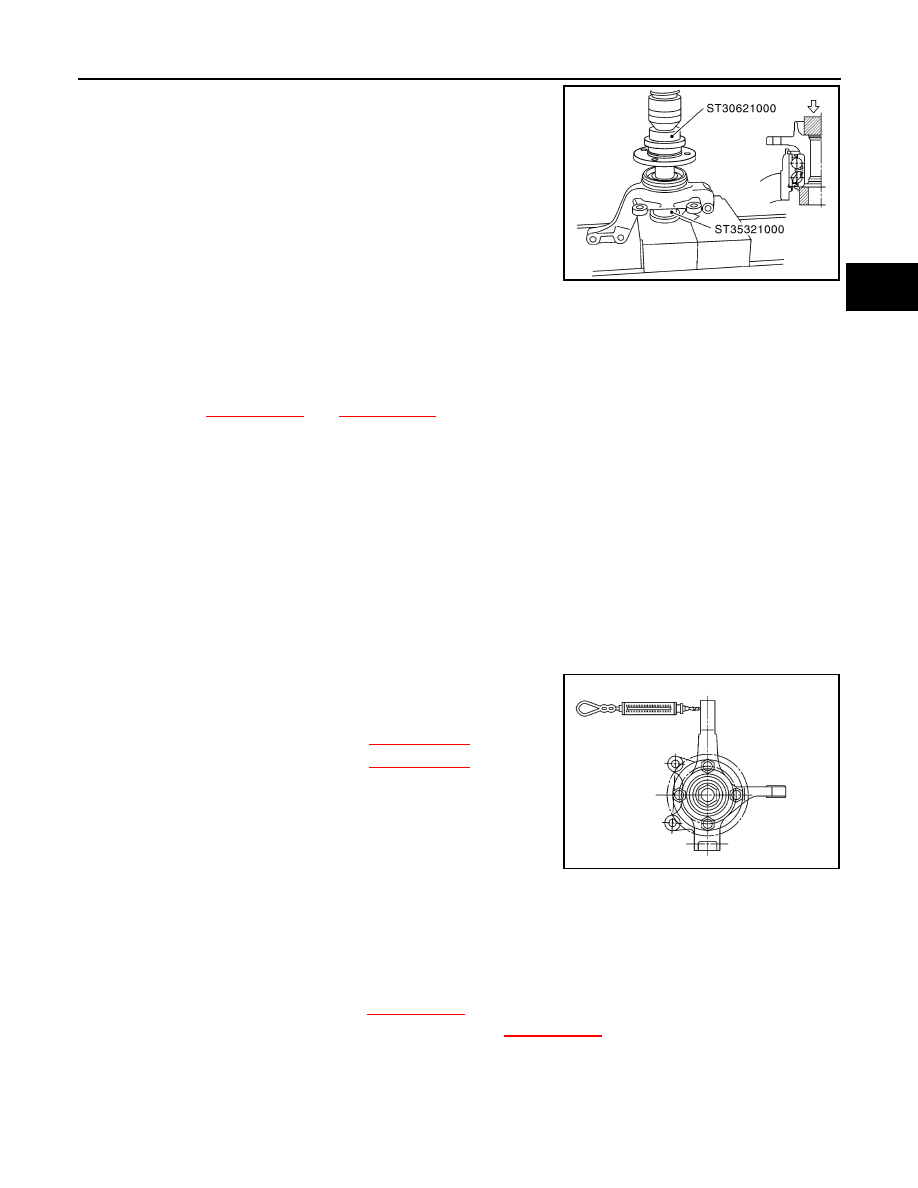

INSPECTION AFTER ASSEMBLY

1.

Apply a load of 34,300 to 49,000 N (3,500 to 5,000 kg, 7,710 - 11,015 lb). In this condition, rotate in for-

ward and reverse directions 10 times each to insure a good fit.

2.

Set a spring balance on strut mounting hole (upper). Measure

rotating torque at an rpm of 8 - 12 rpm.

NOTE:

In case the above loading is not possible

• Assemble drive shaft and tighten wheel hub lock nuts to specified

torque. Then rotate in forward and reverse direction 10 times each

to insure a good fit.

• At a rotating speed of 8 - 12 rpm, place a spring balance on hub bolt to measure torque.

INSPECTION AFTER INSTALLATION

1.

Check the wheel alignment. Refer to

XX-XX, "*****"

.

2.

Adjust neutral position of steering angle sensor. Refer to

XX-XX, "*****"

.

MDIA0037E

Rotating torque

: Refer to

XX-XX, "*****"

.

Spring balance

measurement

: Refer to

XX-XX, "*****"

.

Rotating torque

: 2.32 N·m (0.24 kg-m, 21 in-lb) or less

Spring balance measurement

: 15.9 N (1.6 kg, 3.57 lb) or less

SDIA0762J