Nissan March K13. Manual - part 239

P0138 HO2S2

EC-417

< DTC/CIRCUIT DIAGNOSIS >

[HR12DE (TYPE 2)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0138 HO2S2

DTC Logic

INFOID:0000000006046437

DTC DETECTION LOGIC

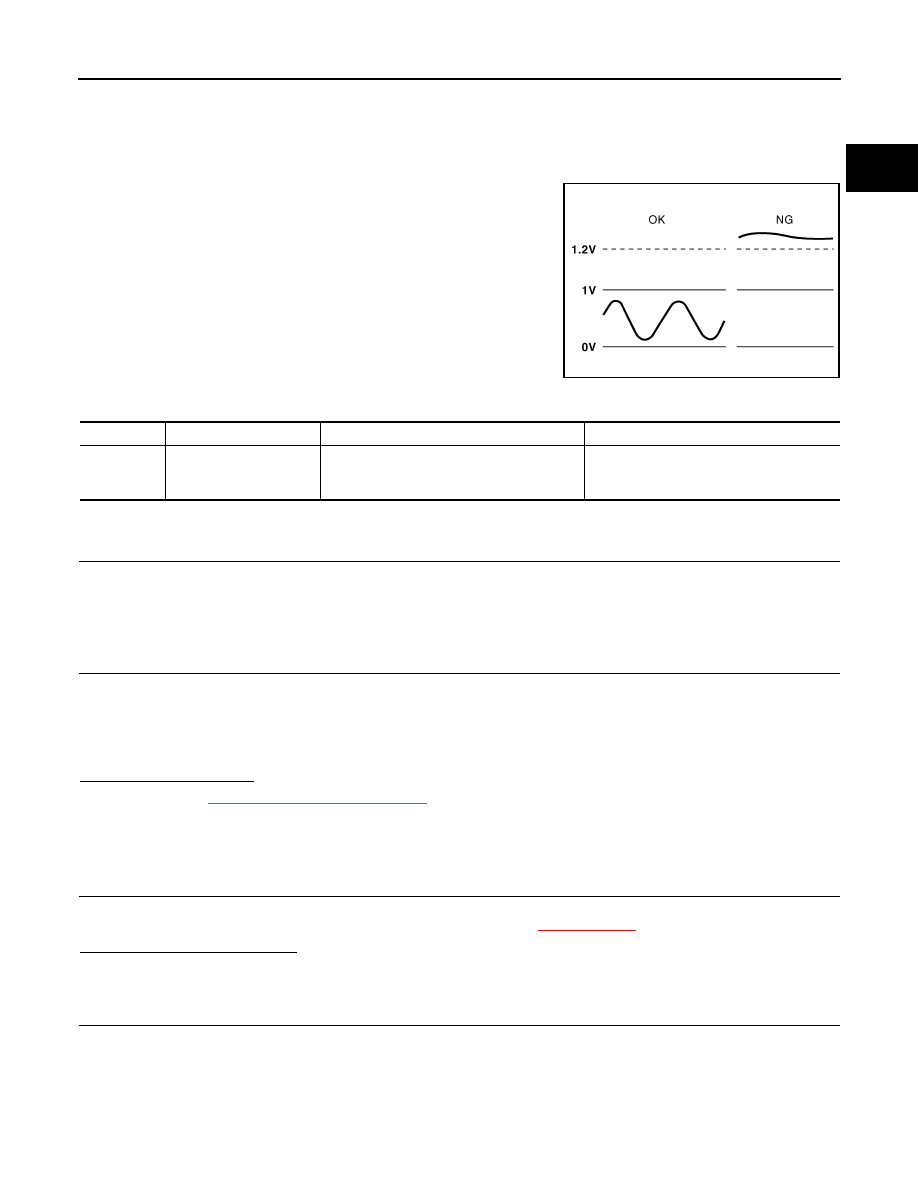

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the heated oxygen sensor 1. The oxygen

storage capacity of the three way catalyst (manifold) causes the

longer switching time.

To judge the malfunctions of heated oxygen sensor 2, ECM monitors

whether the voltage is unusually high during the various driving con-

dition such as fuel cut.

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Start engine and warm it up to normal operating temperature.

2.

Turn ignition switch OFF and wait at least 10 seconds.

3.

Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4.

Let engine idle for 2 minutes.

5.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000006046438

1.

CHECK GROUND CONNECTION

1.

Turn ignition switch OFF.

2.

Check ground connection E38. Refer to Ground Inspection in

XX-XX, "*****"

.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK HO2S2 GROUND CIRCUIT FOR OPEN AND SHORT

1.

Disconnect heated oxygen sensor 2 (HO2S2) harness connector.

2.

Disconnect ECM harness connector.

3.

Check the continuity between HO2S2 harness connector and ECM harness connector.

PBIB1848E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0138

Heated oxygen sensor 2

circuit high voltage

An excessively high voltage from the sensor

is sent to ECM.

• Harness or connectors

(The sensor circuit is open or shorted)

• Heated oxygen sensor 2