Nissan March K13. Manual - part 237

P0132 HO2S1

EC-409

< DTC/CIRCUIT DIAGNOSIS >

[HR12DE (TYPE 2)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0132 HO2S1

DTC Logic

INFOID:0000000005886524

DTC DETECTION LOGIC

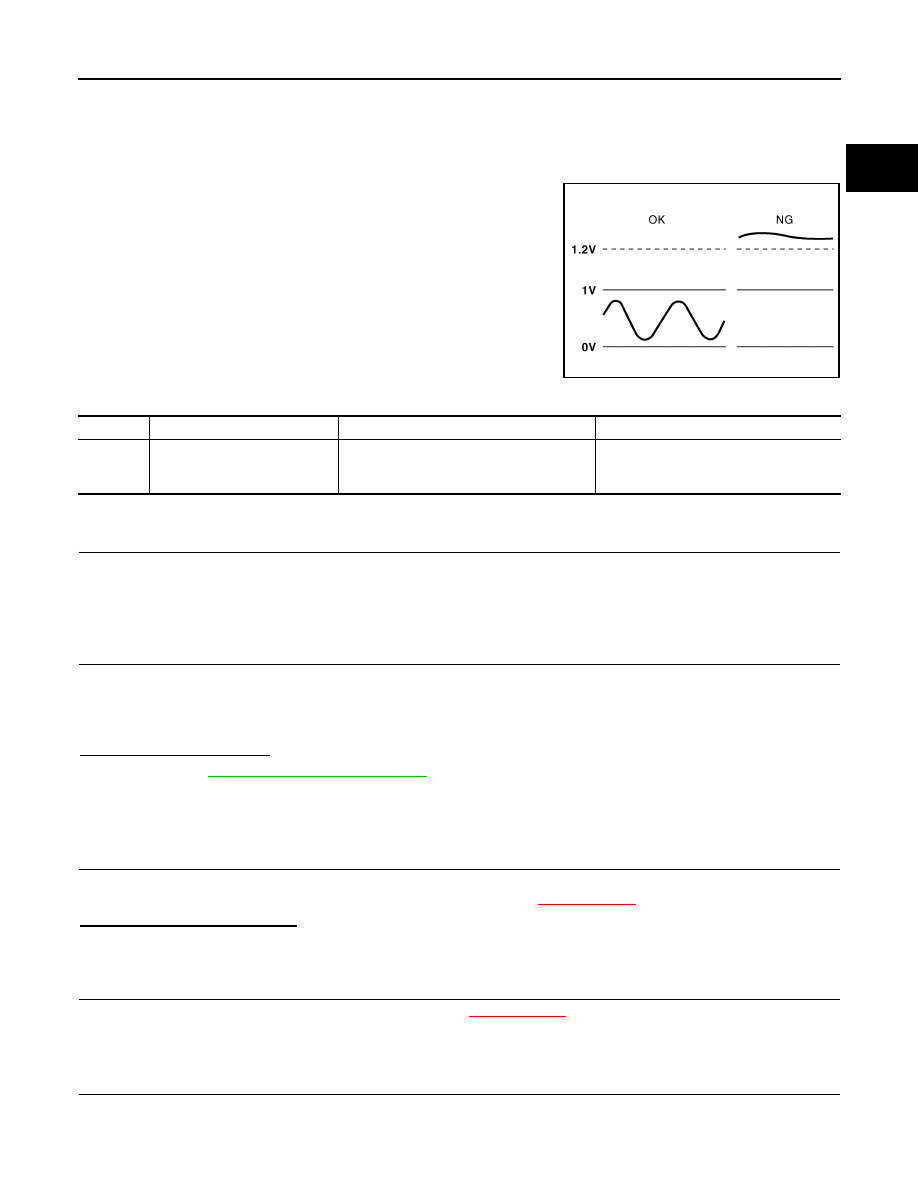

To judge the malfunction, the diagnosis checks that the heated oxy-

gen sensor 1 is not inordinately high.

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Start engine and warm it up to normal operating temperature.

2.

Turn ignition switch OFF and wait at least 10 seconds.

3.

Restart engine and let it idle for 2 minutes.

4.

Check 1st trip DTC.

Is 1st trip DTC is detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000005886525

1.

CHECK GROUND CONNECTION

1.

Turn ignition switch OFF.

2.

Check ground connection E38. Refer to Ground Inspection in

XX-XX, "*****"

.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

RETIGHTEN HEATED OXYGEN SENSOR 1

Loosen and retighten heated oxygen sensor 1. Refer to

XX-XX, "*****"

.

>> GO TO 3.

3.

CHECK HO2S1 GROUND CIRCUIT FOR OPEN AND SHORT

1.

Disconnect heated oxygen sensor 1 (HO2S1) harness connector.

2.

Disconnect ECM harness connector.

PBIB1848E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible Cause

P0132

Heated oxygen sensor 1 circuit

high voltage

An excessively high voltage from the sensor

is sent to ECM.

• Harness or connectors

(The sensor circuit is open or shorted.)

• Heated oxygen sensor 1