Nissan March K13. Manual - part 184

P0335 CKP SENSOR (POS)

EC-197

< DTC/CIRCUIT DIAGNOSIS >

[HR12DE (TYPE 1)]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0335 CKP SENSOR (POS)

DTC Logic

INFOID:0000000005989292

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5 V with igni-

tion switch ON.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Start engine and let it idle for at least 5 seconds.

If engine does not start, crank engine for at least 2 seconds.

2.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000005989293

1.

CHECK CRANKSHAFT POSITION (CKP) SENSOR (POS) POWER SUPPLY CIRCUIT-I

1.

Disconnect crankshaft position (CKP) sensor (POS) harness connector.

2.

Turn ignition switch ON.

3.

Check the voltage between CKP sensor (POS) harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> GO TO 2.

2.

CHECK CRANKSHAFT POSITION (CKP) SENSOR (POS) POWER SUPPLY CIRCUIT-II

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

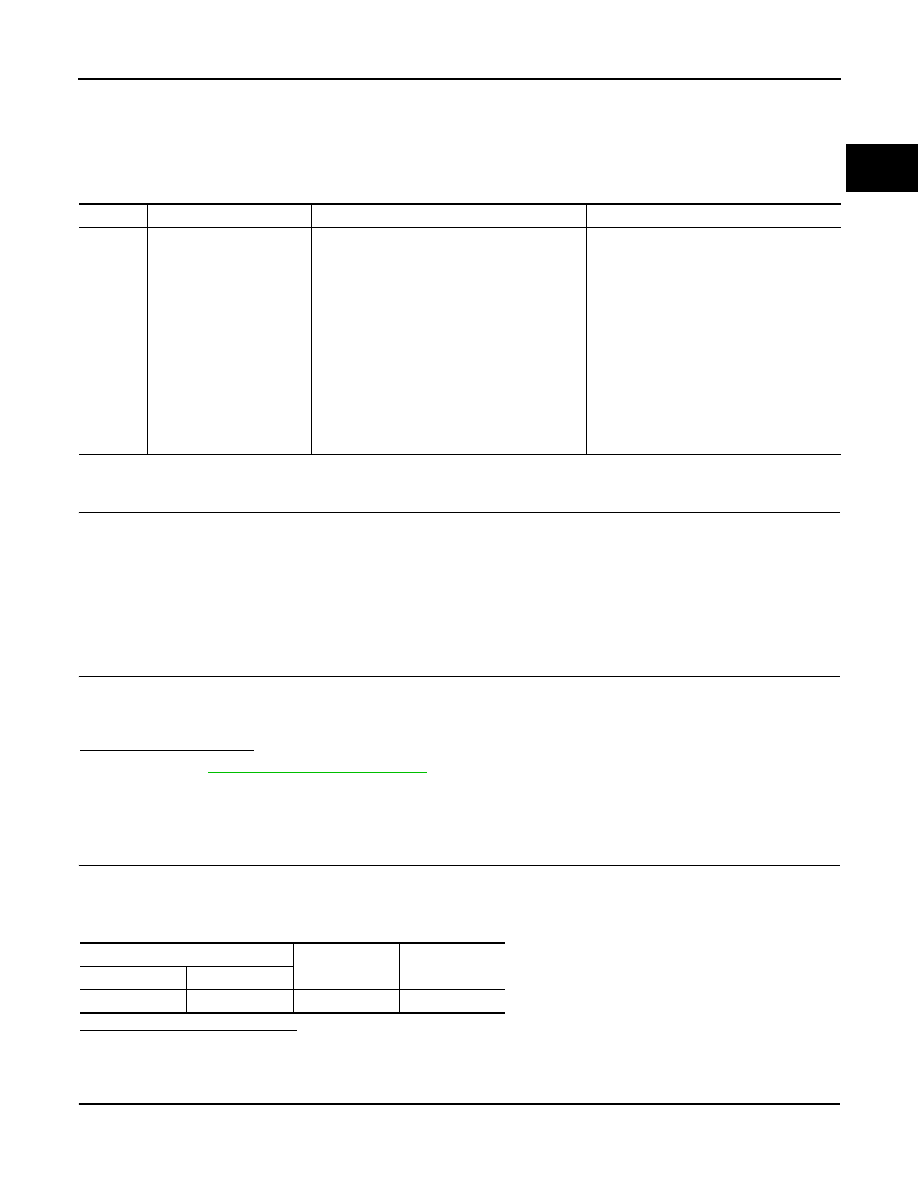

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0335

Crankshaft position sensor

(POS) circuit

• The crankshaft position sensor (POS) signal

is not detected by the ECM during the first

few seconds of engine cranking.

• The proper pulse signal from the crankshaft

position sensor (POS) is not sent to ECM

while the engine is running.

• The crankshaft position sensor (POS) signal

is not in the normal pattern during engine

running.

• Harness or connectors

[Crankshaft position sensor (POS) circuit

is open or shorted.]

(Refrigerant pressure sensor circuit is

shorted.)

(Accelerator pedal position sensor circuit

is shorted.)

(Battery current sensor circuit is shorted.)

• Crankshaft position sensor (POS)

• Refrigerant pressure sensor

• Accelerator pedal position sensor

• Accelerator pedal position sensor

• Signal plate

• Battery current sensor

CKP sensor (POS)

Ground

Voltage

Connector

Terminal

F20

1

Ground

Approx. 5 V