Nissan March K13. Manual - part 41

FRONT DISC BRAKE

BR-37

< REMOVAL AND INSTALLATION >

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

4.

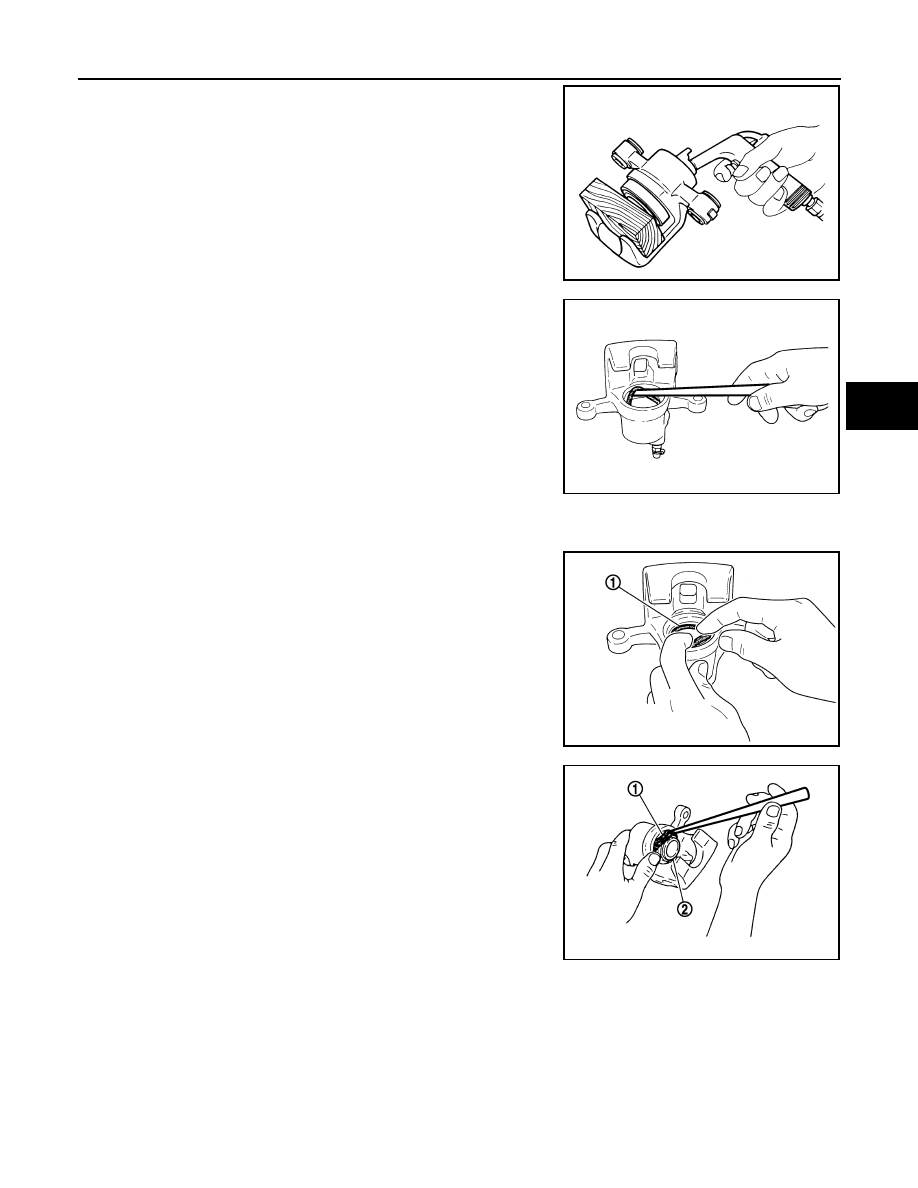

Place a wooden block as shown in the figure, and blow air from

union bolt mounting hole to remove pistons and piston boots.

CAUTION:

Never get fingers caught in the pistons.

5.

Remove piston seal from cylinder body using suitable tool.

CAUTION:

Be careful not to damage a cylinder inner wall.

6.

Remove bleeder valve and cap.

ASSEMBLY

1.

Install bleeder valve and cap.

2.

Apply rubber grease to piston seals (1), and install them to cylin-

der body.

CAUTION:

Never reuse piston seals.

3.

Apply rubber grease to piston boots (1). Cover the piston (2) end

with piston boot, and then install cylinder side lip on piston boot

securely into a groove on cylinder body.

CAUTION:

Never reuse piston boots.

MAA0272D

JPFIA0738ZZ

JPFIA0039ZZ

JPFIA0739ZZ