Nissan GT-R (2007-2014 year). INSTRUMENT PANEL / LAN SYSTEM / MAINTENANCE. Service Manual - part 6

CHASSIS MAINTENANCE

MA-39

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

*3: When the oil does not drop

• Visually check transmission assembly surrounding area (oil seal, drain plug, filler plug, transmission case,

etc.) for smears and leakage of transmission oil. Refer to

MA-32, "TRANSMISSION OIL : Inspection"

OIL LEVEL

CAUTION:

Oil volume cannot be checked by oil level height.

1.

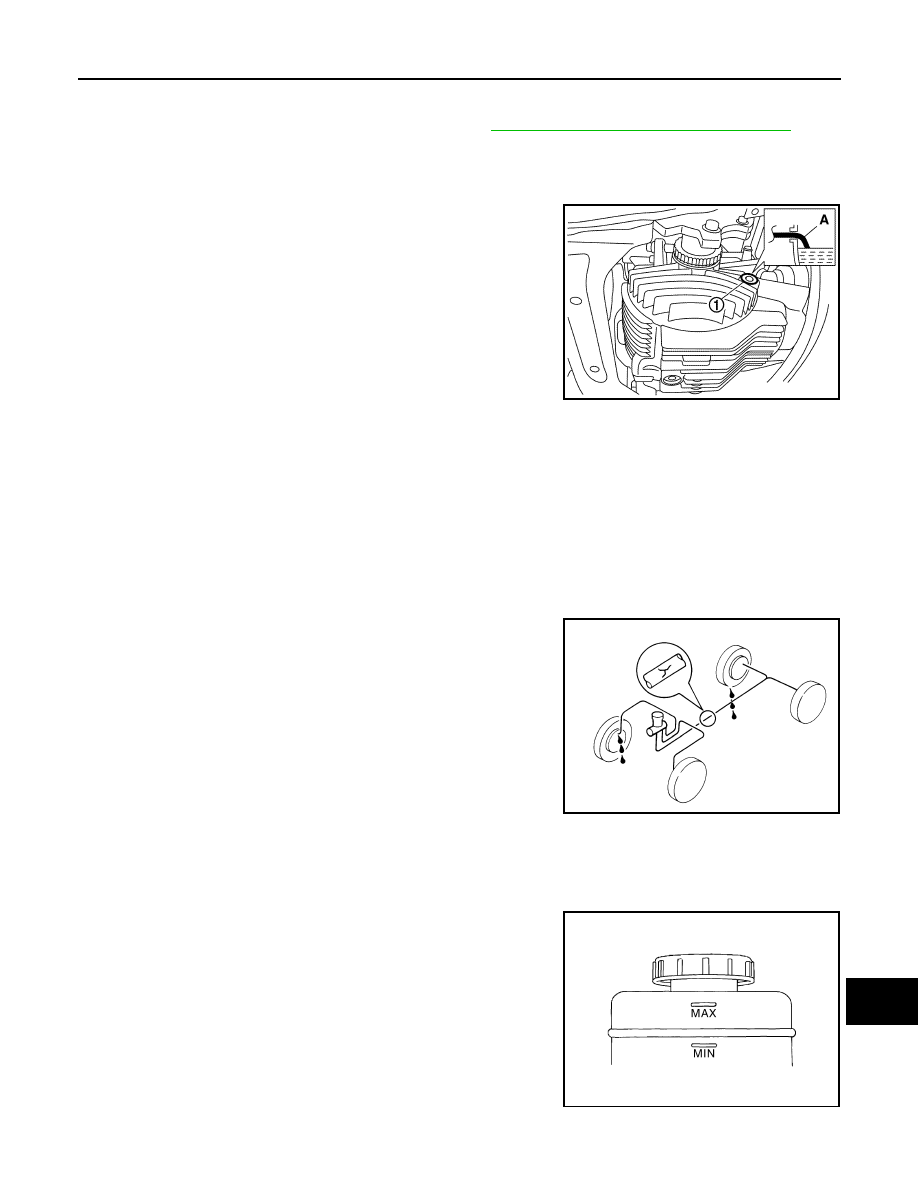

Remove filler plug (1) and gasket.

CAUTION:

Never start engine while checking oil level.

2.

Insert wire (A) etc. from filler plug mounting hole to confirm if the

oil attaches.

• If oil does not attach at the end of the wire, confirm that there

is not leakage, then refill the oil. (This work is recommended to

be performed by GT-R certified NISSAN dealer.)

CAUTION:

Prevent foreign matter from getting into final drive.

3.

Set a gasket on filler plug and install it on final drive, and then

tighten to the specified torque.

CAUTION:

Never reuse gasket.

BRAKE LINES AND CABLES

BRAKE LINES AND CABLES : Inspection

INFOID:0000000009161789

• Check brake fluid lines and parking brake cables for improper

attachment, leaks, chafing, abrasions, deterioration, etc.

BRAKE FLUID

BRAKE FLUID : Inspection

INFOID:0000000009161790

BRAKE FLUID LEVEL

• Check that the fluid level in the reservoir tank is within the specified

range (MAX – MIN lines).

• Visually check for any brake fluid leakage around the reservoir

tank.

• Check the brake system for any leakage if the fluid level is

extremely low (lower than MIN).

• Check the brake system for fluid leakage if the warning lamp

remains illuminated even after the parking brake lever is released.

• Check the reservoir tank for the mixing of foreign matter (e.g. dust)

and oils other than brake fluid.

BRAKE LINE

Standard

Filler plug tightening

torque

: 34.5 N·m (3.5 kg-m, 25 ft-lb)

JPDID0425ZZ

SBR389C

JPFIA0007ZZ

Revision: 2012 November

2014 GT-R