Nissan Pathfinder (2012 year). Manual - part 222

PROPELLER SHAFT

DLN-341

< UNIT REMOVAL AND INSTALLATION >

[PROPELLER SHAFT: 2S1350]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

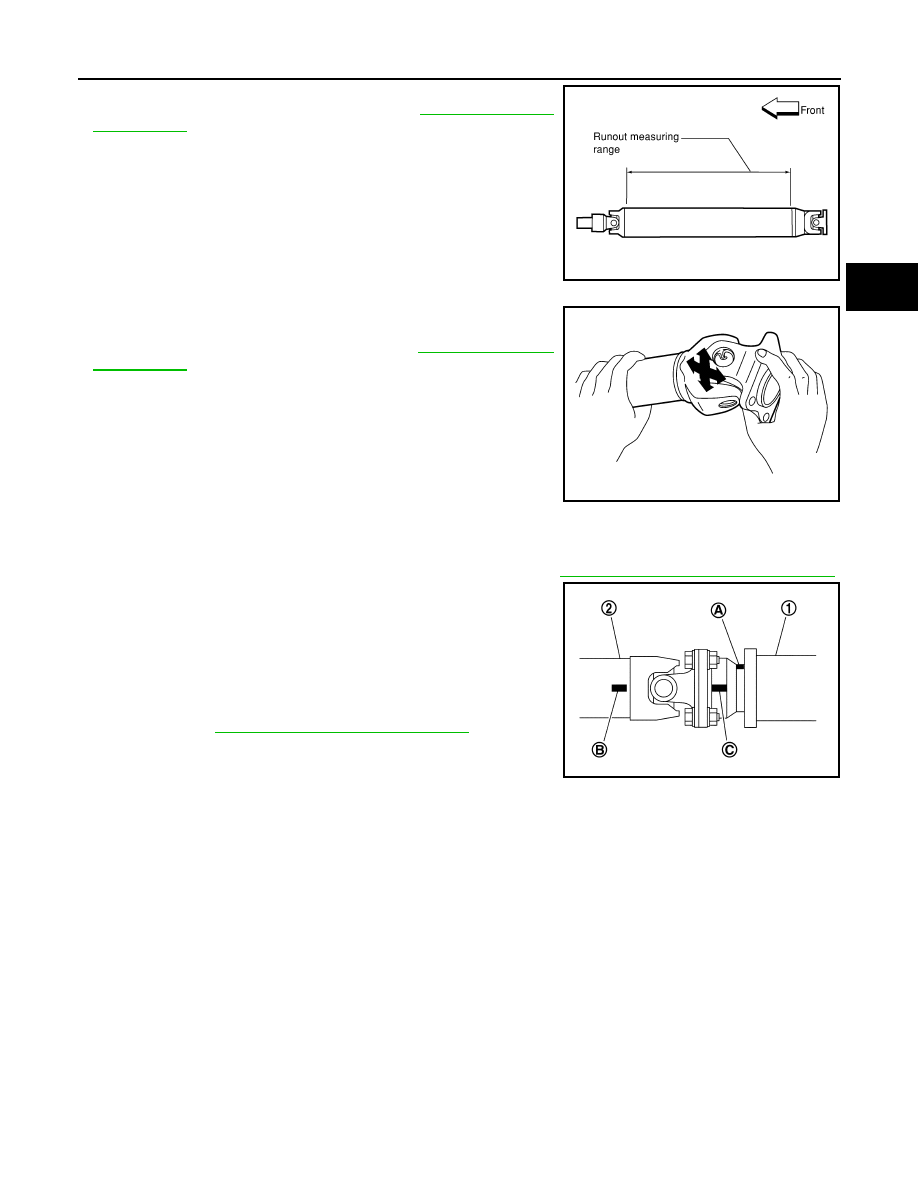

• Inspect the propeller shaft runout. If runout exceeds the limit,

replace the propeller shaft assembly. Refer to

• While holding the flange yoke on one side, check axial play of the

joint as shown. If the journal axial play exceeds the specification,

repair or replace the journal parts. Refer to

• Check the propeller shaft tube for dents or cracks. If damage is

detected, replace the propeller shaft assembly.

INSTALLATION

Installation is in the reverse order of removal.

• After installation, check for vibration by driving the vehicle. Refer to

DLN-338, "NVH Troubleshooting Chart"

.

• If propeller shaft assembly of final drive assembly has been

replaced, connect them as follows:

- Face companion flange mark (A) of the final drive (1) upward. With

the mark (A) faced upward, couple the propeller shaft and the final

drive so that the matching mark (B) of the propeller shaft (2) can be

positioned as close as possible with the matching mark (C) of the

final drive companion flange.

- Tighten propeller shaft and final drive bolts and nuts of the to spec-

DLN-340, "Removal and Installation"

.

CAUTION:

Do not reuse the bolts and nuts. Always install new ones.

LDIA0121E

LDIA0117E

PDIA0892J

August 2012

2012 Pathfinder