Nissan Pathfinder (2012 year). Manual - part 221

SERVICE DATA AND SPECIFICATIONS (SDS)

DLN-333

< SERVICE DATA AND SPECIFICATIONS (SDS)

[PROPELLER SHAFT: 2S1330]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

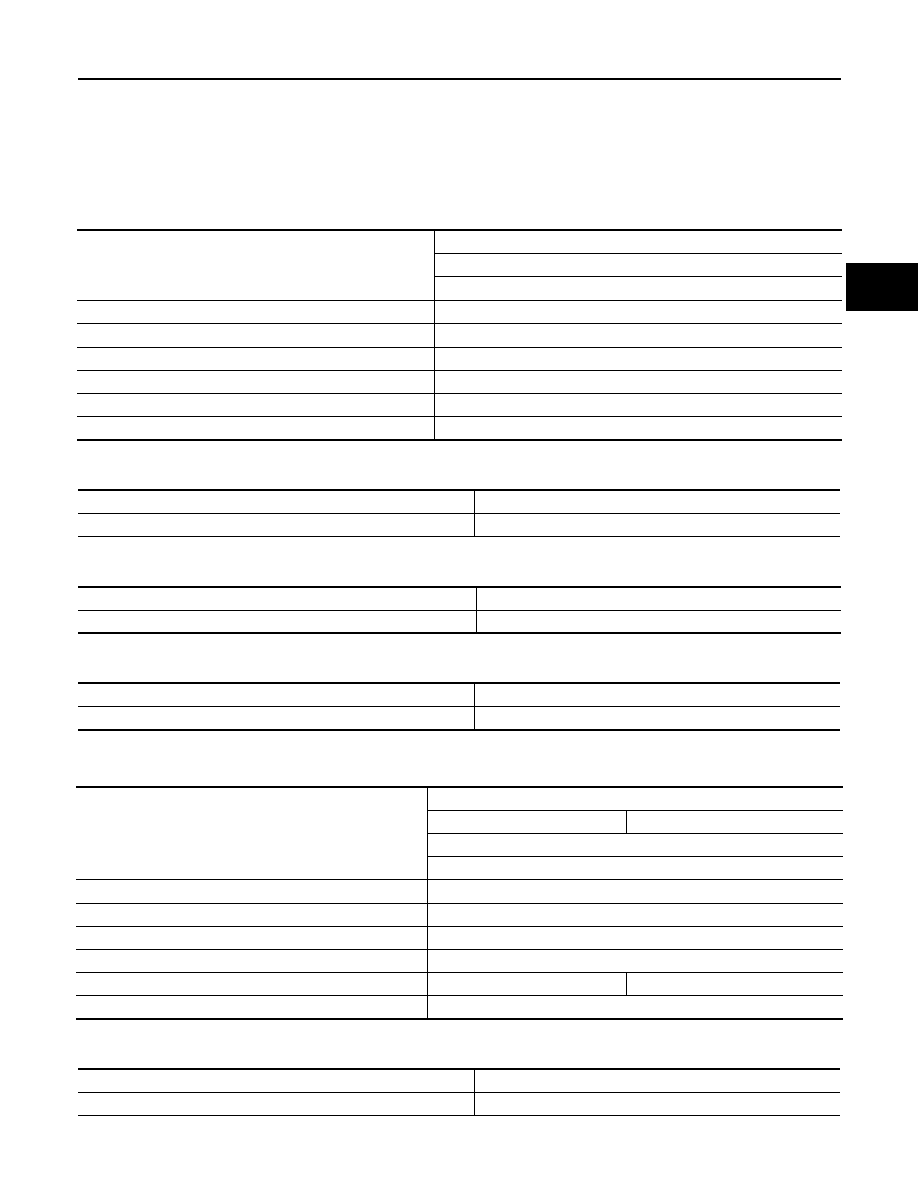

General Specification

INFOID:0000000007357593

2WD models

Unit: mm (in)

PROPELLER SHAFT RUNOUT

Unit: mm (in)

PROPELLER SHAFT JOINT FLEX EFFORT

Unit: N·m (kg-m, in-lb)

JOURNAL AXIAL PLAY

Unit: mm (in)

4WD models

Unit: mm (in)

PROPELLER SHAFT RUNOUT

Unit: mm (in)

PROPELLER SHAFT JOINT FLEX EFFORT

Applied model

2WD

VQ40DE

A/T

Propeller shaft model

2S1330 (aluminum tube)

Number of joints

2

Coupling method with rear final drive

Flange type

Coupling method with transmission

Sleeve type

Shaft length (Spider to spider)

1422.2

±

1.5 (55.99

±

0.06)

Shaft outer diameter

127.6 + 0.22 / - 0.29 (5.02

±

0.01)

Item

Limit

Propeller shaft runout

1.02 (0.0402)

Item

Limit

Propeller shaft joint flex effort

2.26 (0.23, 20) or less

Item

Limit

Journal axial play

0.02 (0.0008) or less

Applied model

4WD

Part time

Full time

VQ40DE

A/T

Propeller shaft model

2S1330 (steel tube)

Number of joints

2

Coupling method with front final drive

Flange type

Coupling method with transfer

Sleeve type

Shaft length (Spider to spider)

952.8

±

1.5 (37.51

±

0.06)

917.8

±

1.5 (36.13

±

0.06)

Shaft outer diameter

76.2 + 0.00 / - 0.13 (3.00 + 0.00/ - 0.01)

Item

Limit

Propeller shaft runout

0.6 (0.024)

August 2012

2012 Pathfinder