Nissan Pathfinder (2012 year). Manual - part 115

BRC-186

< DTC/CIRCUIT DIAGNOSIS >

[TYPE 2]

C1164, C1165, C1166, C1167 CV/SV SYSTEM

*: On for 1 to 2 seconds after the touch, and then Off

Is the inspection result normal?

YES

>> Inspection End.

NO

>> Go to diagnosis procedure. Refer to

BRC-184, "Diagnosis Procedure"

Special Repair Requirement

INFOID:0000000007818505

1.

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

Always perform neutral position adjustment for the steering angle sensor when replacing the ABS actuator

and electric unit (control unit). Refer to

BRC-121, "ADJUSTMENT OF STEERING ANGLE SENSOR NEU-

>> GO TO 2

2.

CALIBRATION OF DECEL G SENSOR

Always perform calibration of decel G sensor when replacing the ABS actuator and electric unit (control unit).

BRC-122, "CALIBRATION OF DECEL G SENSOR : Description"

.

>> END

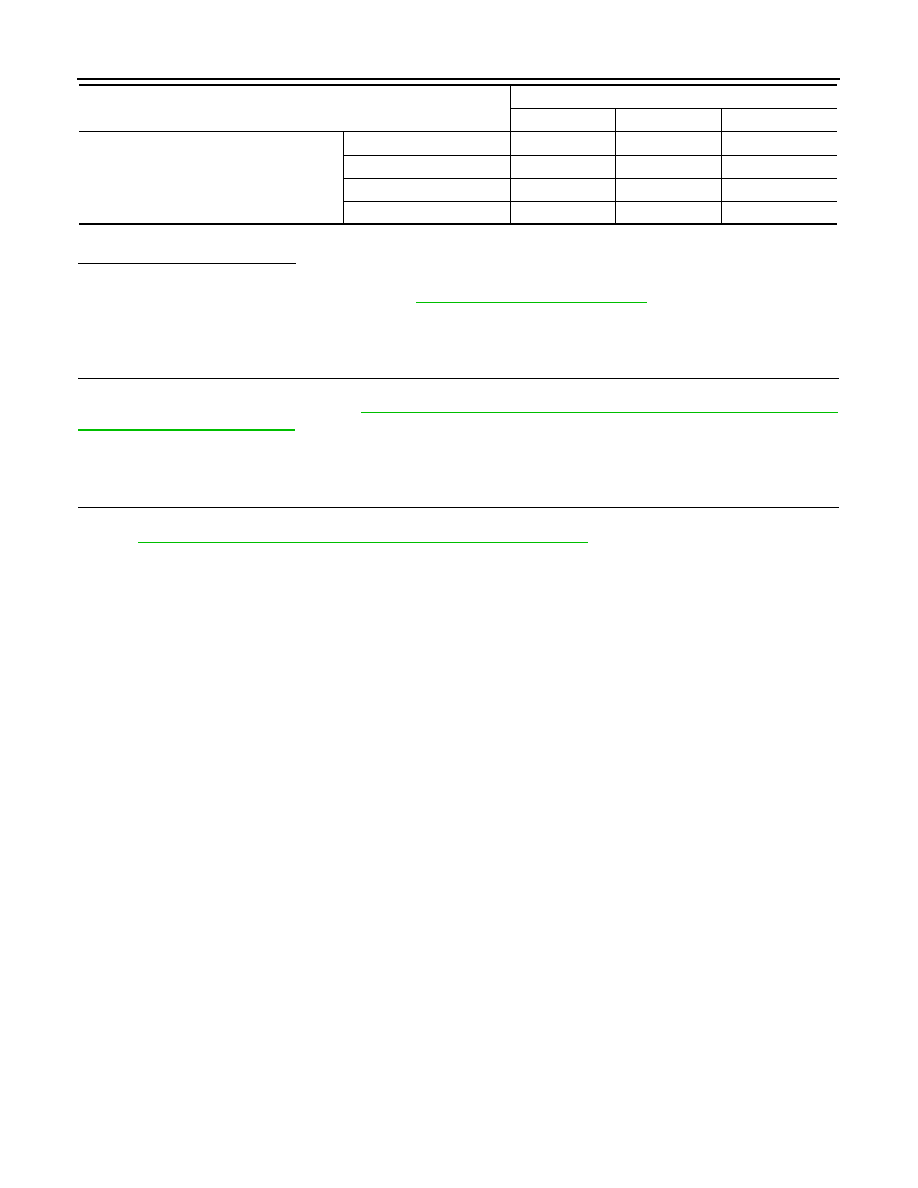

RR LH ABS SOLENOID (ACT)

RR LH IN SOL

Off

Off

Off

RR LH OUT SOL

Off

Off

Off

CV2

Off

On

On

SV2

Off

On*

Off

Operation

ABS solenoid valve (ACT)

Up

ACT UP

ACT KEEP

August 2012

2012 Pathfinder