Nissan Pathfinder (2011 year). Manual - part 270

EC-214

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE]

P0300, P0301, P0302, P0303, P0304, P0305, P0306 MISFIRE

14.

CHECK IGNITION TIMING

Check the following items. Refer to

OK or NG

OK

>> GO TO 15.

NG

>> Follow the

15.

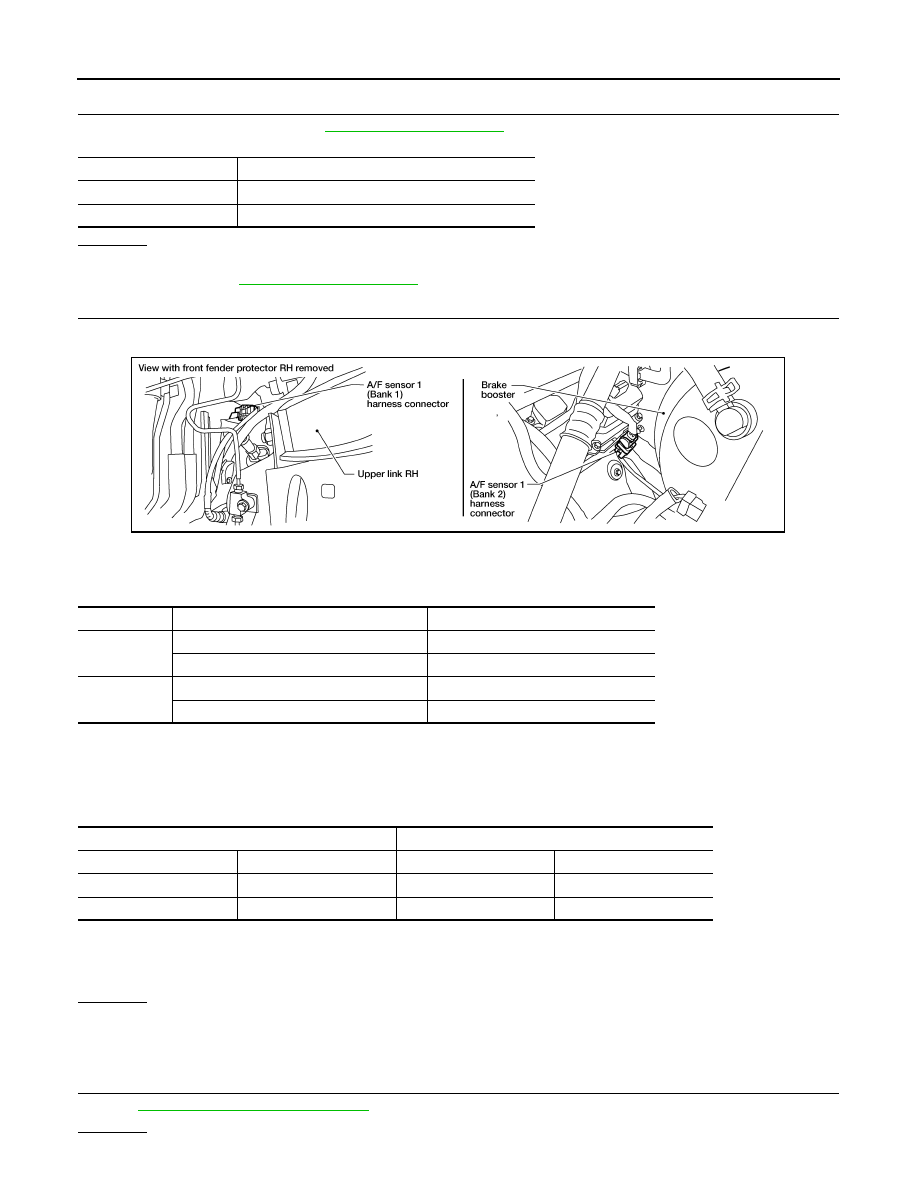

CHECK A/F SENSOR 1 INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect A/F sensor 1 harness connector.

3. Disconnect ECM harness connector.

4. Check harness continuity between A/F sensor 1 terminal and ECM terminal as follows.

Refer to Wiring Diagram.

5. Check harness continuity between the following terminals and ground.

Refer to Wiring Diagram.

6. Also check harness for short to power.

OK or NG

OK

>> GO TO 16.

NG

>> Repair open circuit or short to ground or short to power in harness or connectors between ECM

and A/F sensor 1.

16.

CHECK A/F SENSOR 1 HEATER

EC-105, "Component Inspection"

OK or NG

Items

Specifications

Target idle speed

625

±

50 rpm (in P or N position)

Ignition timing

15

±

5

°

BTDC (in P or N position)

A/F sensor 1 terminal

ECM terminal

Bank 1

1

35

2

56

Bank 2

1

16

2

75

Continuity should exist.

Bank 1

Bank 2

A/F sensor 1 terminal

ECM terminal

A/F sensor 1 terminal

ECM terminal

1

35

1

16

2

56

2

75

Continuity should not exist.

BBIA0544E

2011 Pathfinder