Nissan Pathfinder (2011 year). Manual - part 271

EC-222

< DTC/CIRCUIT DIAGNOSIS >

[VQ40DE]

P0335 CKP SENSOR (POS)

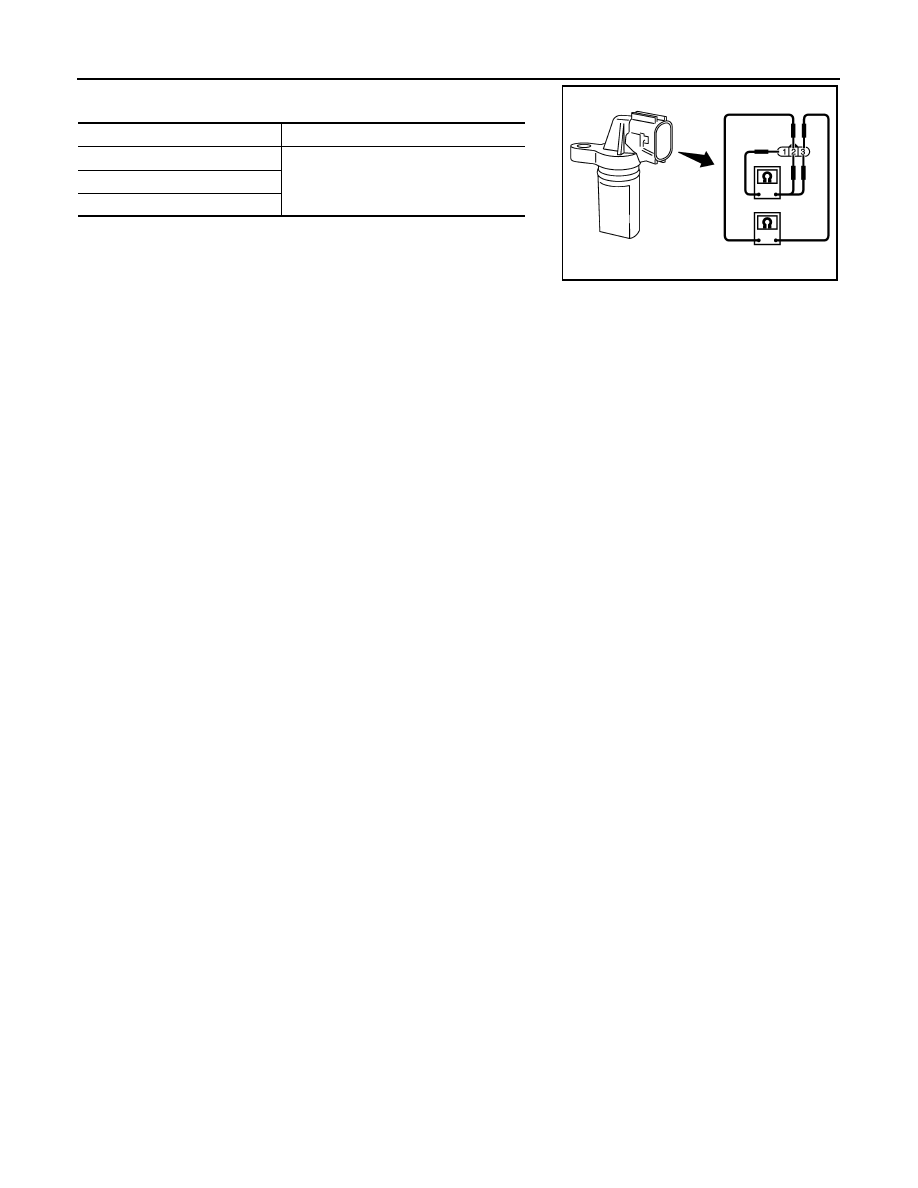

5. Check resistance as shown in the figure.

Terminal No. (Polarity)

Resistance

Ω

[at 25

°

C (77

°

F)]

1 (+) - 2 (-)

Except 0 or

∞

1 (+) - 3 (-)

2 (+) - 3 (-)

PBIB0564E

2011 Pathfinder