Nissan Pathfinder (2010 year). Manual - part 417

FAX-18

< DISASSEMBLY AND ASSEMBLY >

DRIVE SHAFT

6. Remove any old grease on the housing using paper towels.

Wheel Side

1. Mount the drive shaft in a vise.

CAUTION:

When mounting the drive shaft in a vise, use copper or aluminum plates between the vise and the

drive shaft.

2. Remove the boot bands, then remove the boot from the joint sub-assembly.

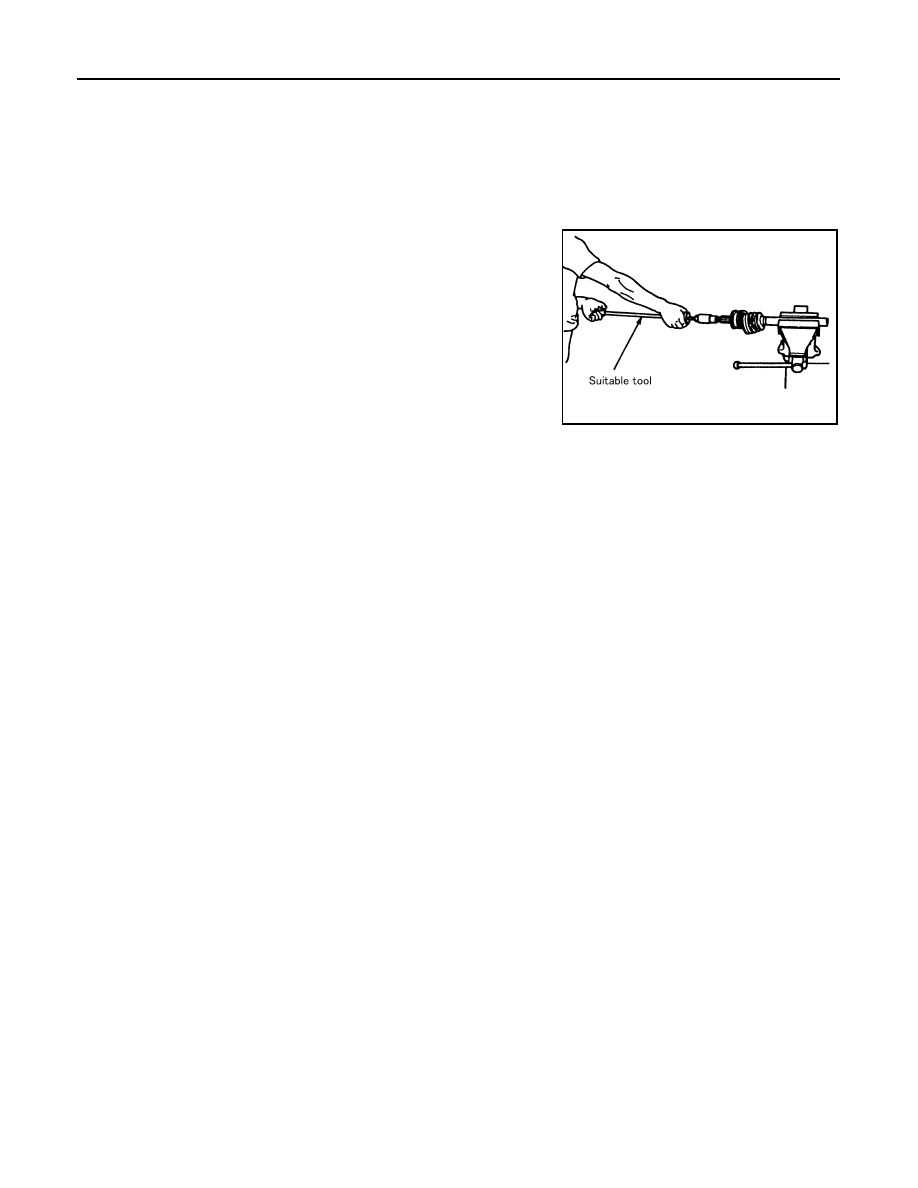

3. Screw a suitable drive shaft puller 30 mm (1.18 in) or more into

the threaded part of the joint sub-assembly. Pull the joint sub-

assembly off of the drive shaft as shown.

NOTE:

Align the sliding hammer and drive shaft and remove the joint

sub-assembly by pulling directly.

CAUTION:

• If the joint sub-assembly cannot be removed after five or

more attempts, replace the drive shaft and joint sub-

assembly as a set.

4. Remove the boot from the drive shaft.

5. Remove the circlip from the drive shaft.

6. While rotating the ball cage, remove any old grease from the joint sub-assembly using paper towels.

INSPECTION AFTER DISASSEMBLY

Drive Shaft

• Replace the drive shaft if there is any runout, cracking, or other damage.

Joint Sub-assembly

• Check for any rough rotation or unusual axial looseness.

• Clean any foreign material from inside the joint sub-assembly.

• Check for any compression scars, cracks, or fractures.

CAUTION:

If any defective conditions are found in the joint sub-assembly components, replace the entire joint

sub-assembly.

Sliding Joint Side Housing

• Check for any compression scars, cracks, fractures, or unusual wear on the ball rolling surface.

• Check for any damage to the drive shaft screws.

• Check for any deformation of the boot installation components.

Ball Cage

• Check the sliding surface for any compression scars, cracks, or fractures.

Steel Ball

• Check for any compression scars, cracks, fractures, or unusual wear.

Inner Race

• Check the ball sliding surface for any compression scars, cracks, or fractures.

• Check for any damage to the serrated part.

CAUTION:

If any defective conditions are found, install a new housing, ball cage, steel ball, and inner race as a

set.

ASSEMBLY

Final Drive Side

SDIA0606E

2010 Pathfinder