Nissan Pathfinder (2010 year). Manual - part 381

EM-176

< ON-VEHICLE REPAIR >

[VK56DE]

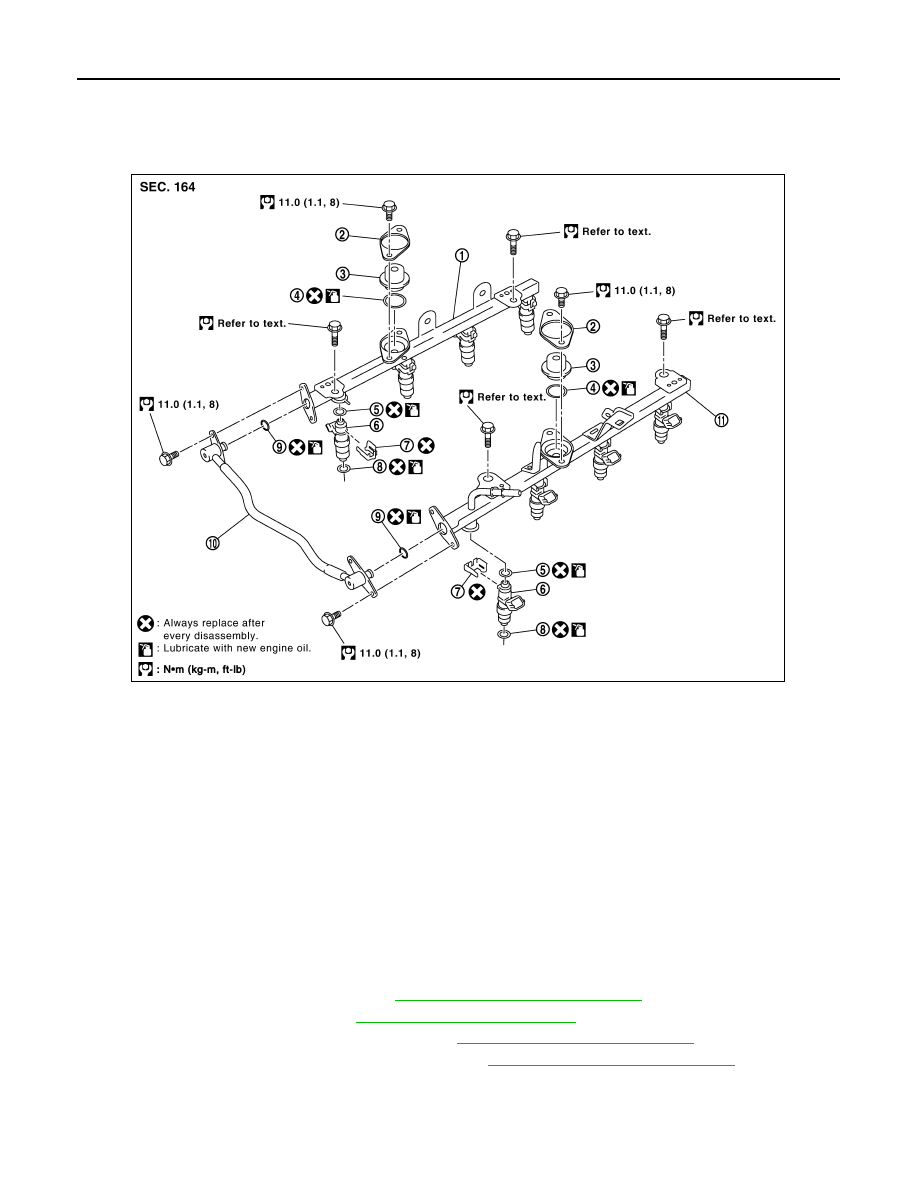

FUEL INJECTOR AND FUEL TUBE

FUEL INJECTOR AND FUEL TUBE

Exploded View

INFOID:0000000005260518

Removal and Installation

INFOID:0000000005260519

CAUTION:

Do not remove or disassemble parts unless instructed as shown.

REMOVAL

WARNING:

• Put a “CAUTION FLAMMABLE” sign in the workshop.

• Be sure to work in a well ventilated area and furnish workshop with a CO

2

fire extinguisher.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from the work area.

• To avoid the danger of being scalded, do not drain engine coolant when engine is hot.

1. Remove the engine room cover. Refer to

EM-160, "Removal and Installation"

2. Release the fuel pressure. Refer to

3. Disconnect the battery negative terminal. Refer to

PG-78, "Removal and Installation"

4. Remove the air duct and resonator assembly. Refer to

EM-161, "Removal and Installation"

5. Disconnect the EVAP canister purge control solenoid valve harness connector.

6. Disconnect the fuel injector harness connectors.

7. Disconnect the fuel hose assembly from the fuel tubes (RH and LH).

1.

Fuel tube (RH)

2.

Cap

3.

Fuel damper

4.

O-ring

5.

O-ring (blue)

6.

Fuel injector

7.

Clip

8.

O-ring (brown)

9.

O-ring

10. Fuel hose assembly

11. Fuel tube (LH)

KBIA2472E

2010 Pathfinder