Nissan Pathfinder (2010 year). Manual - part 120

BODY REPAIR

BRM-41

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

M

A

B

BRM

N

O

P

-

Remove foam material remaining on vehicle side.

-

Clean area in which foam was removed.

-

Install service part.

-

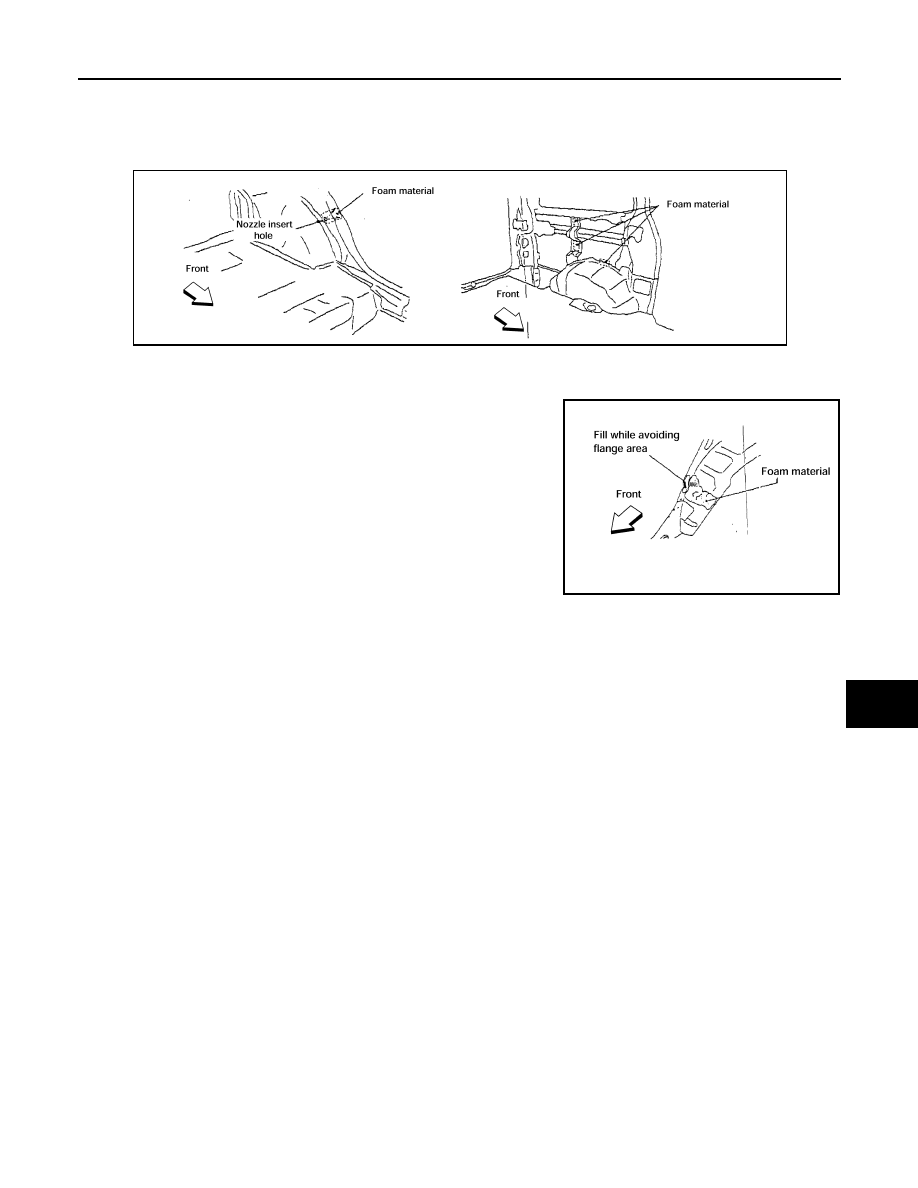

Insert nozzle into hole near fill area and fill foam material or fill in enough to close gap with the service

part.

2. Fill procedures before installation of service part.

-

Remove foam material remaining on vehicle side.

-

Clean area in which foam was removed.

-

Fill foam material on wheelhouse outer side.

NOTE:

Fill in enough to close gap with service part while avoiding flange

area.

-

Install service part.

NOTE:

Refer to label for information on working times.

Replacement Operation

INFOID:0000000005259214

DESCRIPTION

This section is prepared for technicians who have attained a high level of skill and experience in repairing col-

lision-damaged vehicles and also use modern service tools and equipment. Persons unfamiliar with body

repair techniques should not attempt to repair collision-damaged vehicles by using this section.

Technicians are also encouraged to read Body Repair Manual (Fundamentals) in order to ensure that the orig-

inal functions and quality of the vehicle can be maintained. The Body Repair Manual (Fundamentals) contains

additional information, including cautions and warnings, that are not including in this manual. Technicians

should refer to both manuals to ensure proper repairs.

Please note that this information is prepared for worldwide usage, and as such, certain procedures may not

apply in some regions or countries.

LIIA1081E

LIIA1082E

2010 Pathfinder