Nissan Pathfinder (2007 year). Manual - part 203

DTC P1217 ENGINE OVER TEMPERATURE

EC-491

C

D

E

F

G

H

I

J

K

L

M

A

EC

2007 Pathfinder

4.

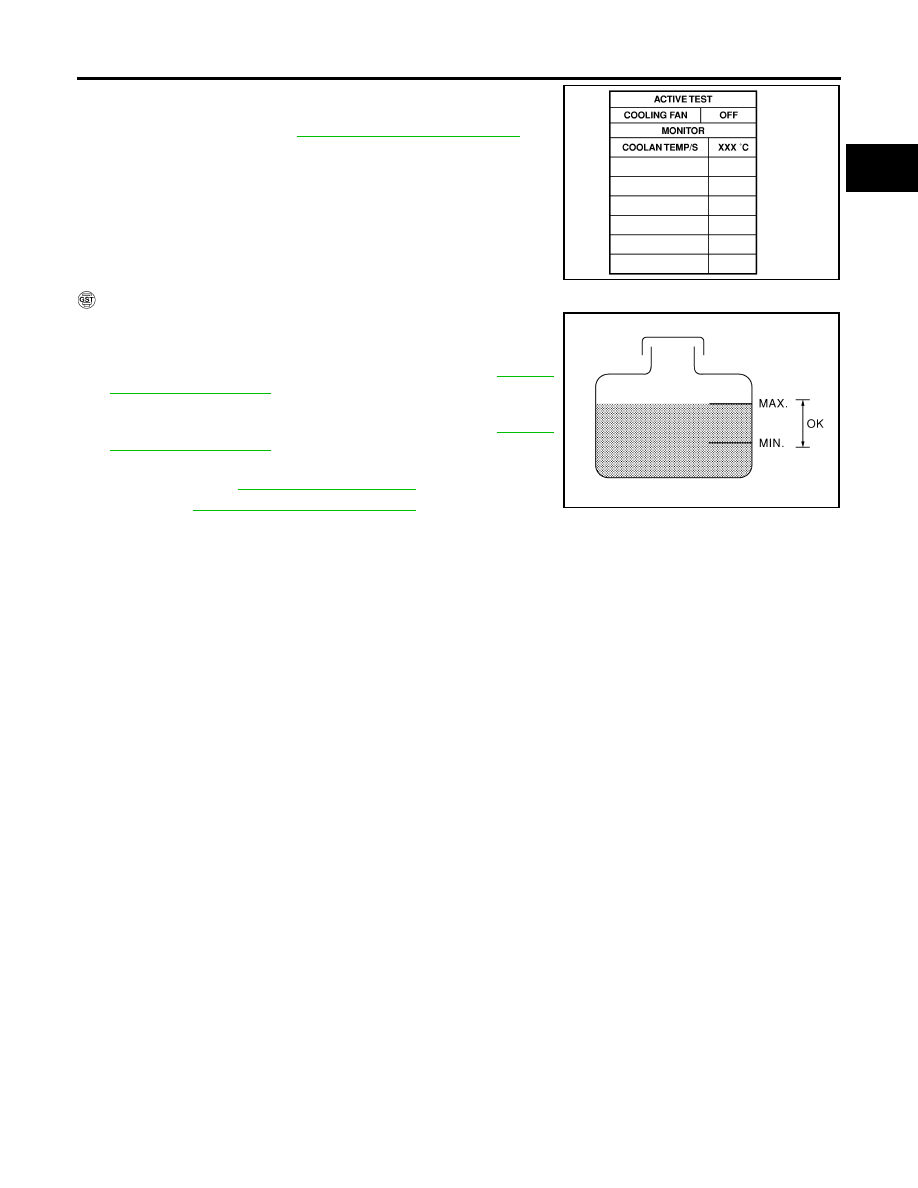

Perform “COOLING FAN” in “ACTIVE TEST” mode with CON-

SULT-II.

5.

If the results are NG, go to

EC-494, "Diagnostic Procedure"

WITH GST

1.

Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to

2.

Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to

3.

Perform IPDM E/R auto active test and check cooling fan motor

operation, refer to

.

4.

If NG, go to

EC-494, "Diagnostic Procedure"

.

SEF646X

SEF621W