Nissan Pathfinder (2007 year). Manual - part 182

DTC P0172, P0175 FUEL INJECTION SYSTEM FUNCTION

EC-323

C

D

E

F

G

H

I

J

K

L

M

A

EC

2007 Pathfinder

5.

DETECT MALFUNCTIONING PART

Check the following.

●

Fuel pump and circuit (Refer to,

.)

●

Fuel pressure regulator (Refer to

>> Repair or replace.

6.

CHECK MASS AIR FLOW SENSOR

With CONSULT-II

1.

Install all removed parts.

2.

Check “MASS AIR FLOW” in “DATA MONITOR” mode with CONSULT-II.

OK or NG

OK

>> GO TO 8.

NG

>> Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or

ground. Refer to

.

7.

CHECK MASS AIR FLOW SENSOR

With GST

1.

Install all removed parts.

2.

Check mass air flow sensor signal in Service $01 with GST.

OK or NG

OK (P0172)>>GO TO 9.

OK (P0175)>>GO TO 11.

NG

>> Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or

ground. Refer to

.

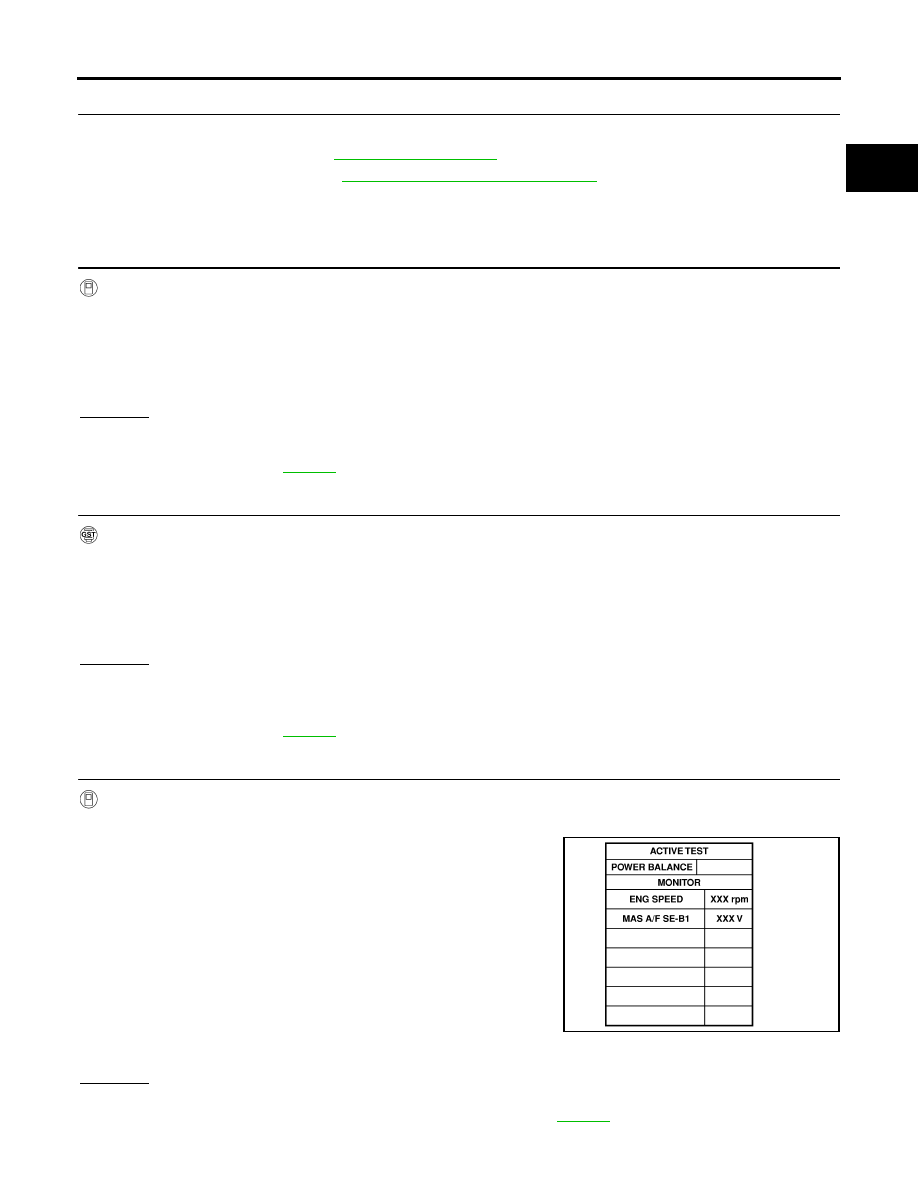

8.

CHECK FUNCTION OF FUEL INJECTOR

With CONSULT-II

1.

Start engine.

2.

Perform “POWER BALANCE” in “ACTIVE TEST” mode with

CONSULT-II.

3.

Make sure that each circuit produces a momentary engine

speed drop.

OK or NG

OK

>> GO TO 12.

NG

>> Perform trouble diagnosis for FUEL INJECTOR, refer to

2.0 - 6.0 g·m/sec:

at idling

7.0 - 20.0 g·m/sec:

at 2,500 rpm

2.0 - 6.0 g·m/sec:

at idling

7.0 - 20.0 g·m/sec:

at 2,500 rpm

PBIB0133E