Nissan Pathfinder (2007 year). Manual - part 152

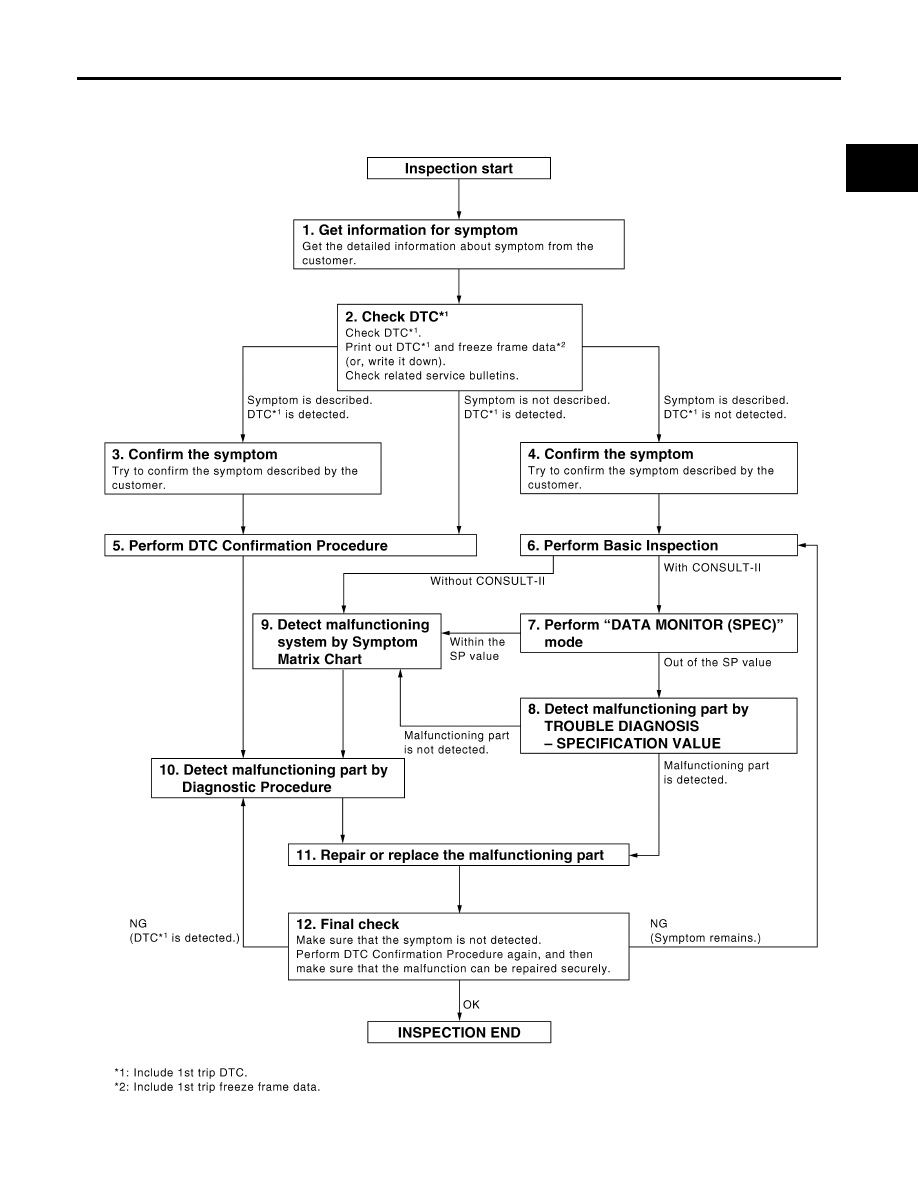

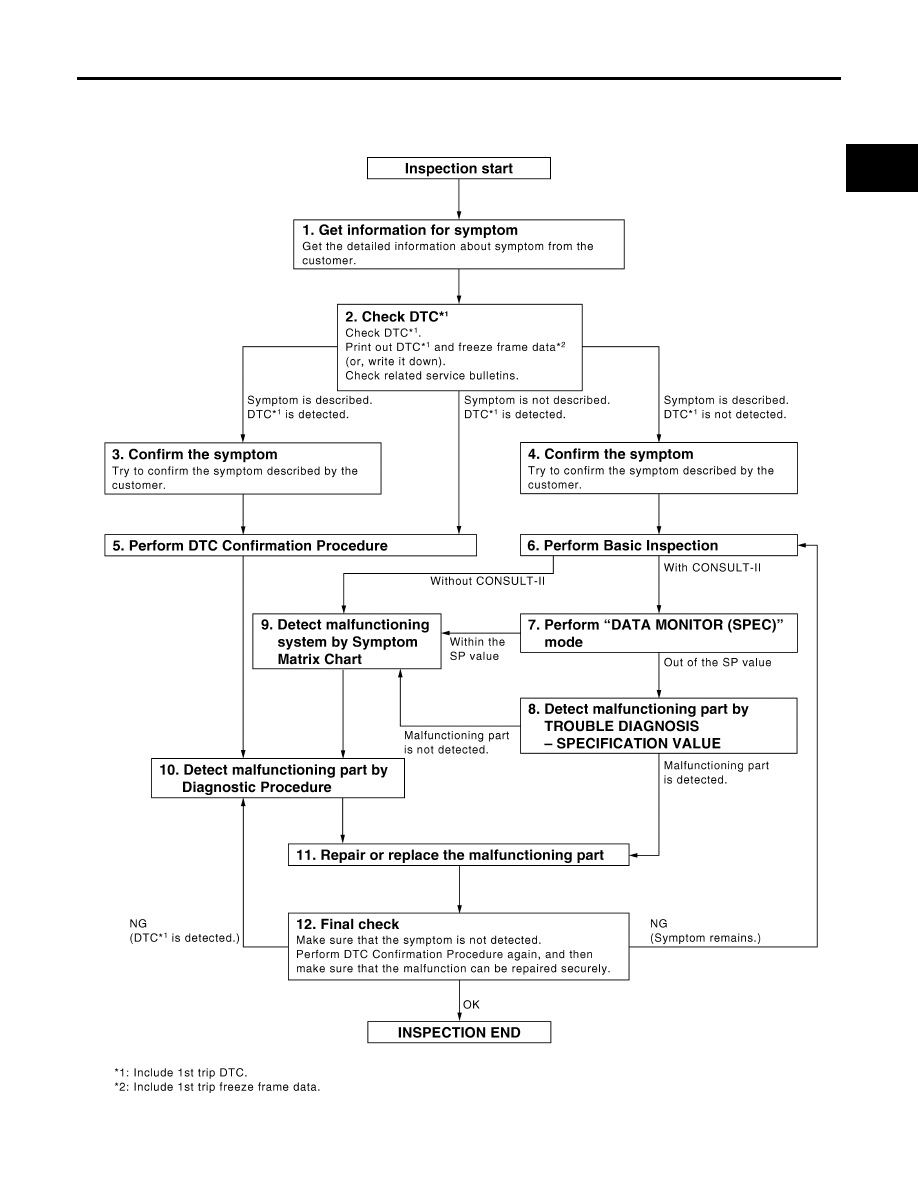

TROUBLE DIAGNOSIS

EC-83

C

D

E

F

G

H

I

J

K

L

M

A

EC

2007 Pathfinder

WORK FLOW

Overall Sequence

PBIB2267E

|

|

|

TROUBLE DIAGNOSIS EC-83 C D E F G H I J K L M A EC 2007 Pathfinder WORK FLOW PBIB2267E |