Nissan Pathfinder (2007 year). Manual - part 45

PRECAUTIONS

ATC-11

C

D

E

F

G

H

I

K

L

M

A

B

ATC

2007 Pathfinder

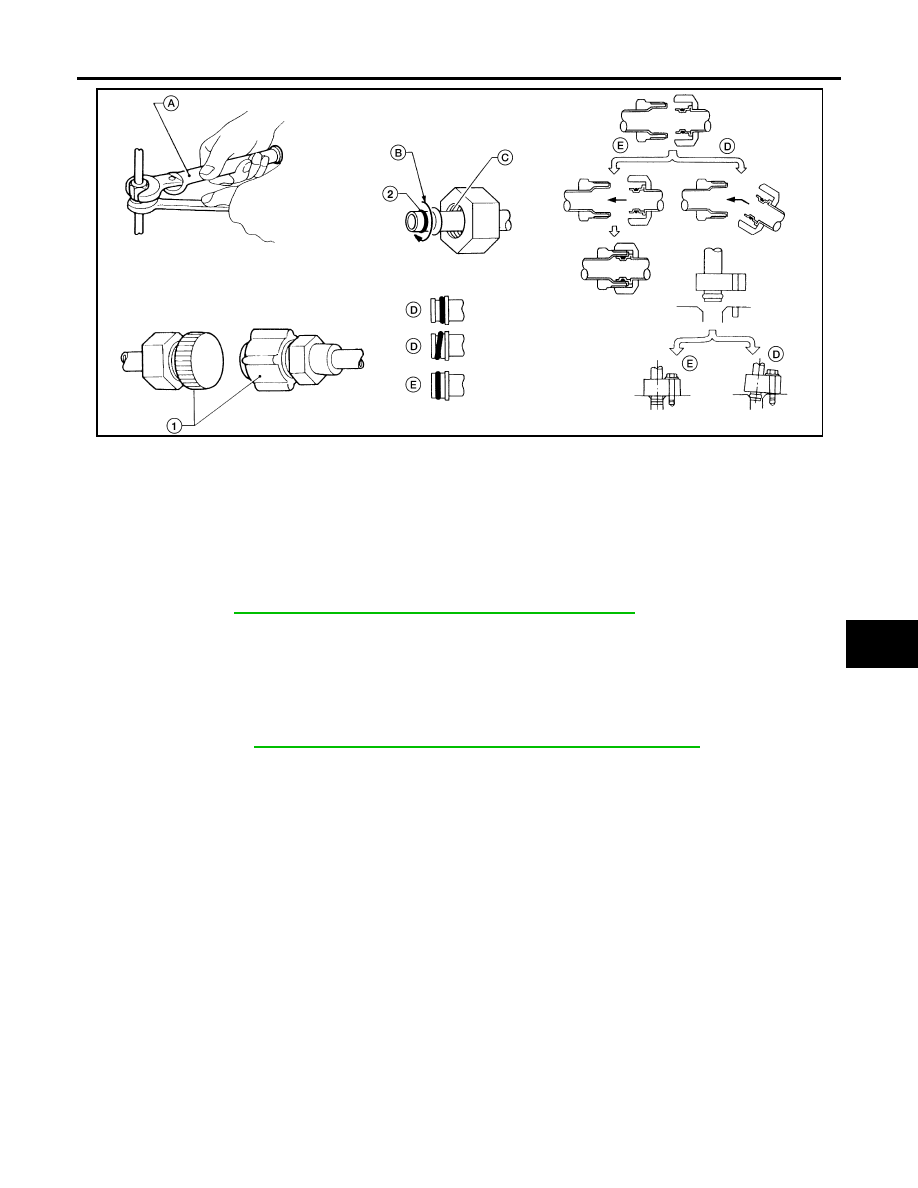

Precautions for Servicing Compressor

EJS004OD

●

Plug all openings to prevent moisture and foreign matter from entering.

●

When the compressor is removed, store it in the same position as it is when mounted on the car.

●

When replacing or repairing compressor, follow “Maintenance of Oil Quantity in Compressor”

exactly. Refer to

ATC-22, "Maintenance of Oil Quantity in Compressor"

●

Keep friction surfaces between clutch and pulley clean. If the surface is contaminated with oil,

wipe it off by using a clean waste cloth moistened with thinner.

●

After compressor service operation, turn the compressor shaft by hand more than 5 turns in both

directions. This will equally distribute oil inside the compressor. After the compressor is installed,

let the engine idle and operate the compressor for 1 hour.

●

After replacing the compressor magnet clutch, apply voltage to the new one and check for normal

operation. Refer to

ATC-163, "Removal and Installation for Compressor Clutch"

Precautions for Service Equipment

EJS004OE

RECOVERY/RECYCLING EQUIPMENT

Follow the manufacturer's instructions for machine operation and machine maintenance. Never introduce any

refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Follow the manufacturer's instructions for tester operation and tester maintenance.

1.

Plug

2.

O-ring

A.

Torque wrench

B.

Apply oil

C.

Do not apply oil to thread

D.

No good

E.

Good

WJIA1994E