Nissan Pathfinder (2006 year). Manual - part 340

TROUBLE DIAGNOSIS

MTC-73

C

D

E

F

G

H

I

K

L

M

A

B

MTC

2006 Pathfinder

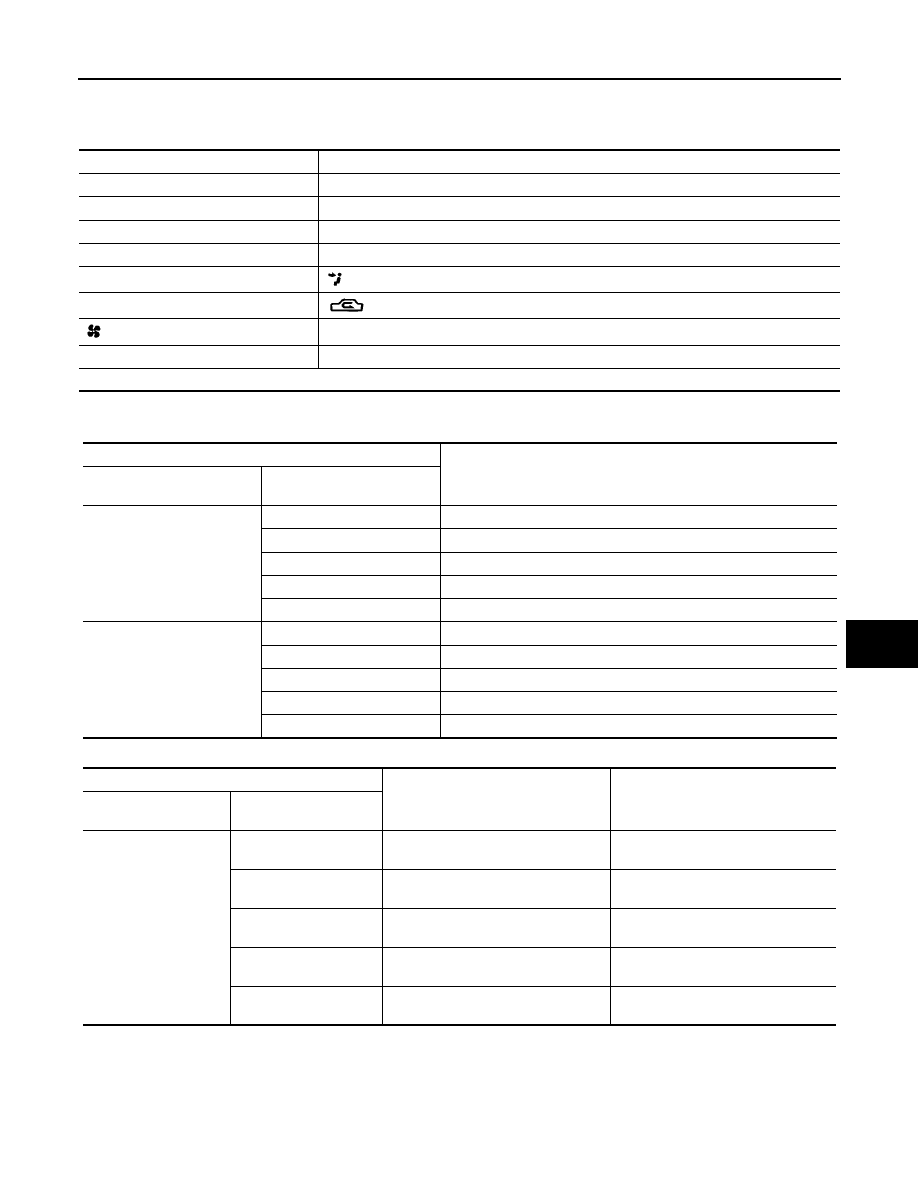

PERFORMANCE CHART

Test Condition

Testing must be performed as follows:

Test Reading

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Vehicle location

Indoors or in the shade (in a well-ventilated place)

Doors

Closed

Door window

Open

Hood

Open

TEMP.

Max. COLD

Mode switch

(Ventilation) set

Recirculation (REC) switch

(Recirculation) set

Blower speed

Max. speed set

Engine speed

Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°

C (

°

F)

Relative humidity

%

Air temperature

°

C (

°

F)

50 - 60

20 (68)

5.3 - 6.5 (42 - 44)

25 (77)

9.7 - 11.5 (49 - 53)

30 (86)

13.8 - 16.3 (57 - 61)

35 (95)

18.0 - 21.2 (64 - 70)

40 (104)

22.2 - 25.7 (72 - 78)

60 - 70

20 (68)

6.5 - 7.7 (44 - 46)

25 (77)

11.5 - 13.3 (53 - 56)

30 (86)

16.3 - 18.8 (61 - 66)

35 (95)

21.2 - 24.0 (70 - 75)

40 (104)

25.7 - 29.2 (78 - 85)

Ambient air

High-pressure (Discharge side)

kPa (kg/cm

2

, psi)

Low-pressure (Suction side)

kPa (kg/cm

2

, psi)

Relative humidity

%

Air temperature

°

C (

°

F)

50 - 70

20 (68)

680 - 840

(6.94 - 8.57, 98.6 - 121.8)

160 - 198

(1.63 - 2.02, 23.2 - 28.7)

25 (77)

800 - 985

(8.16 - 10.05, 116.0 - 142.8)

198 - 245

(2.02 - 2.50, 28.7 - 35.5)

30 (86)

940 - 1,150

(9.59 - 11.73, 136.3 - 166.8)

225 - 278

(2.30 - 2.84, 32.6 - 40.3)

35 (95)

1,160 - 1,410

(11.83 - 14.38, 168.2 - 204.5)

273 - 335

(2.78 - 3.42, 39.6 - 48.6)

40 (104)

1,325 - 1,620

(13.52 - 16.52, 192.1 - 234.9)

325 - 398

(3.32 - 4.06, 47.1 - 57.7)