Nissan Pathfinder (2006 year). Manual - part 164

DTC P0037, P0038, P0057, P0058 HO2S2 HEATER

EC-171

C

D

E

F

G

H

I

J

K

L

M

A

EC

2006 Pathfinder

DTC Confirmation Procedure

UBS00K54

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is between 10.5V and 16V at

idle.

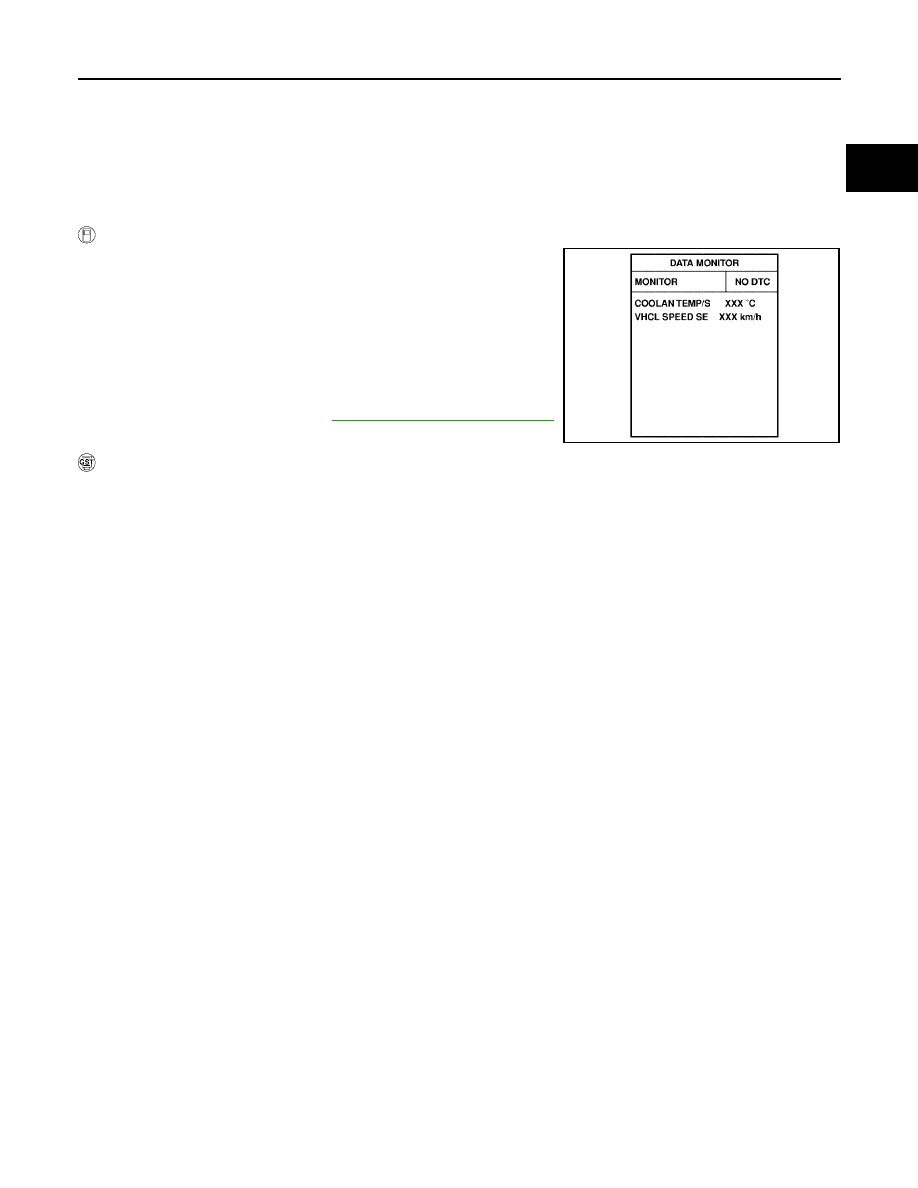

WITH CONSULT-II

1.

Turn ignition switch ON and select “DATA MONITOR” mode with

CONSULT-II.

2.

Start engine and warm it up to the normal operating tempera-

ture.

3.

Turn ignition switch OFF and wait at least 10 seconds.

4.

Start the engine and keep the engine speed between 3,500 rpm

and 4,000 rpm for at least 1 minute under no load.

5.

Let engine idle for 1 minute.

6.

If 1st trip DTC is detected, go to

EC-175, "Diagnostic Procedure"

.

WITH GST

Follow the procedure “WITH CONSULT-II” above.

SEF176Y