Nissan Pathfinder (2006 year). Manual - part 112

BRAKE BOOSTER

BR-19

C

D

E

G

H

I

J

K

L

M

A

B

BR

2006 Pathfinder

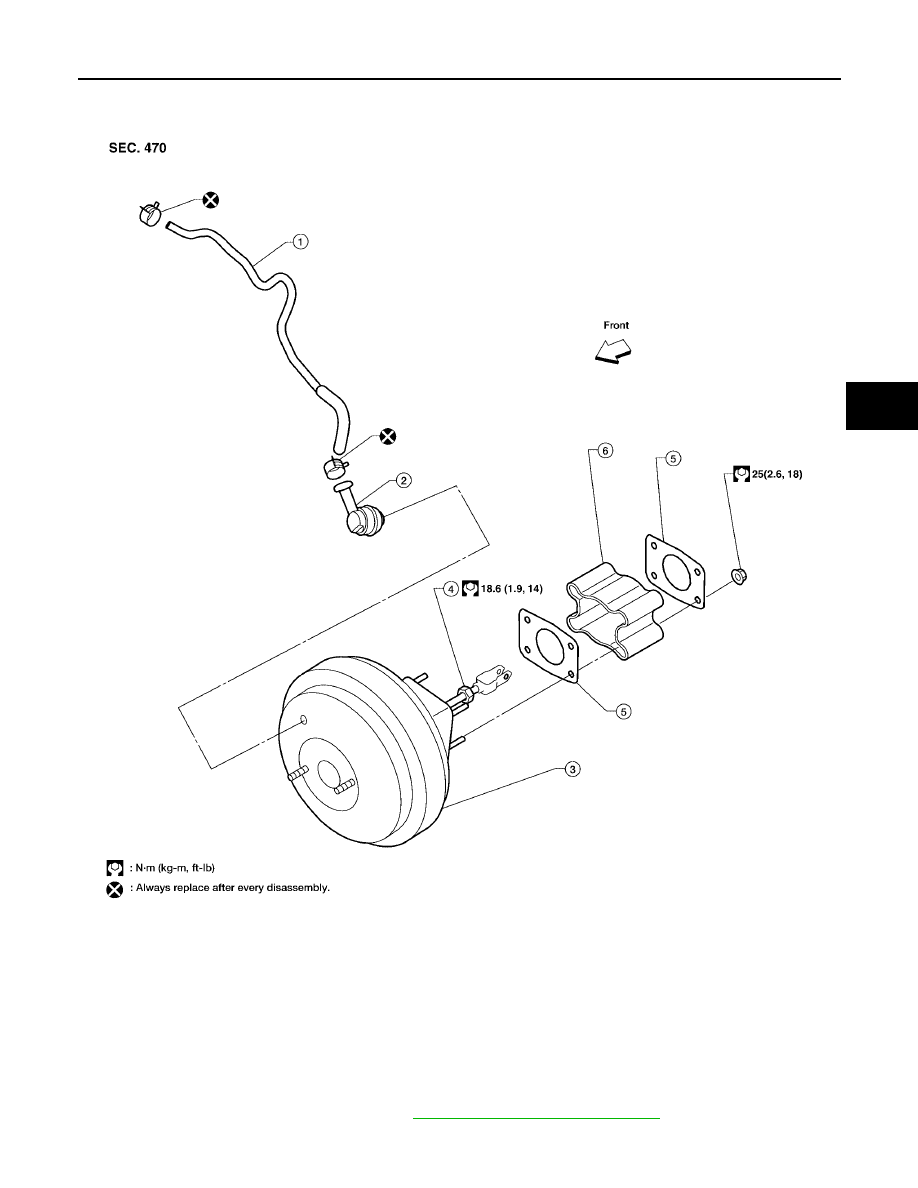

Removal and Installation

EFS0063R

Brake Booster

REMOVAL

CAUTION:

●

Be careful not to deform or bend brake piping while removing and installing brake booster.

●

Replace clevis pin if it is damaged.

●

Be careful not to damage brake booster stud bolt threads. If brake booster is tilted or inclined dur-

ing installation, dash panel may damage the threads.

●

Attach the check valve in the correct direction.

1.

Remove actuator and electric unit. Refer to

BRC-62, "Removal and Installation"

.

2.

Remove brake piping from brake master cylinder.

LFIA0241E

1.

Brake booster hose

2.

Brake booster vacuum check valve

3.

Brake booster

4.

Lock nut

5.

Gasket

6.

Spacer block