Nissan Teana J32. Manual - part 621

FRONT COIL SPRING AND STRUT

FSU-9

< ON-VEHICLE REPAIR >

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

ON-VEHICLE REPAIR

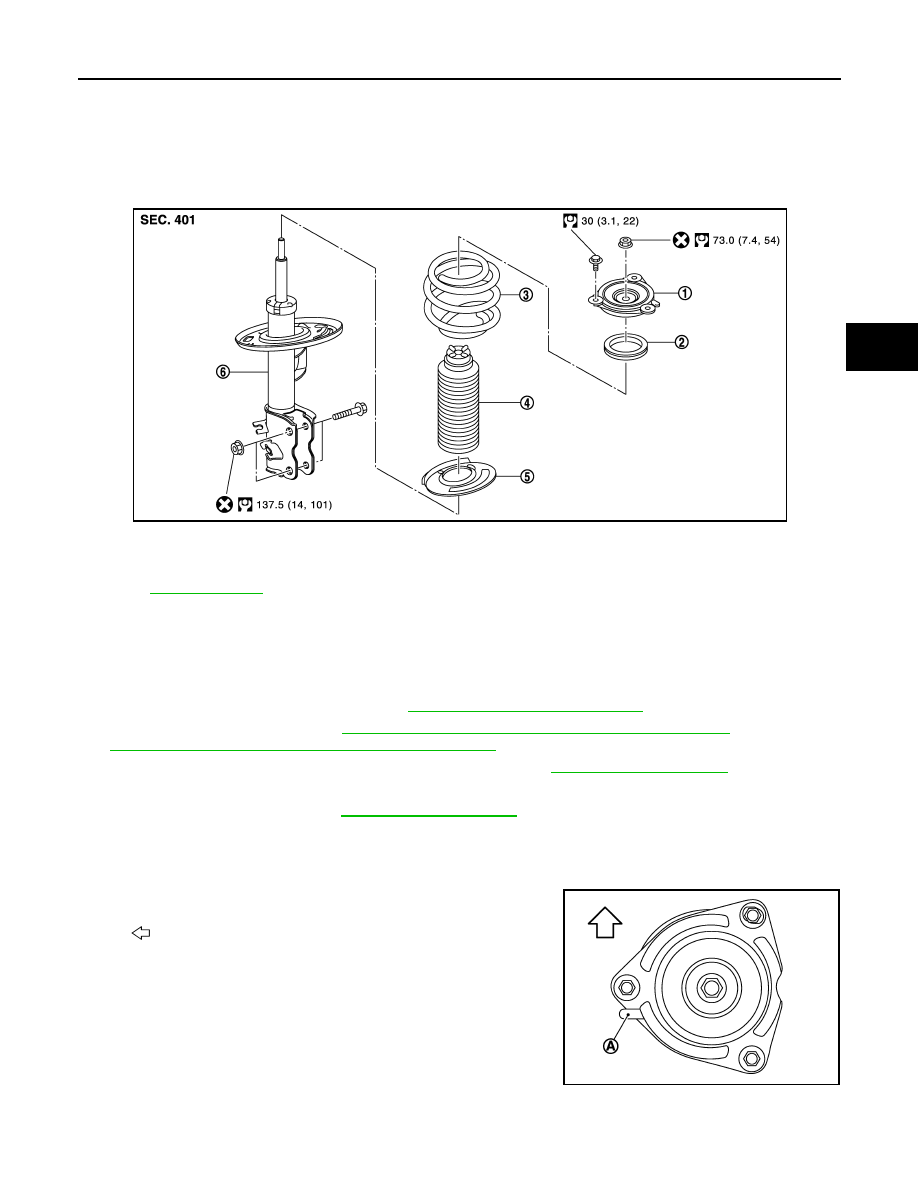

FRONT COIL SPRING AND STRUT

Exploded View

INFOID:0000000003811116

Removal and Installation

INFOID:0000000003811117

REMOVAL

1.

Remove tires.

2.

Remove lock plate of brake hose. Refer to

BR-19, "FRONT : Exploded View"

3.

Remove wheel sensor. Refer to

BRC-57, "FRONT WHEEL SENSOR : Exploded View"

BRC-151, "FRONT WHEEL SENSOR : Exploded View"

4.

Remove stabilizer connecting rod from strut assembly. Refer to

.

5.

Remove strut assembly from steering knuckle.

6.

Remove cowl top cover. Refer to

7.

Remove mounting bolts of strut mounting insulator, and then remove strut assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Become it in projection (A) an illustration to the vehicle outside.

• Perform final tightening of bolts and nuts, under unladen conditions

with tires on level ground.

1.

Strut mounting insulator

2.

Strut mounting bearing

3.

Coil spring

4.

Bound bumper

5.

Lower rubber seat

6.

Strut

Refer to

JPEIA0112GB

: Vehicle front

JPEIA0094ZZ