Nissan Teana J32. Manual - part 618

FL-8

< ON-VEHICLE REPAIR >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

INSTALLATION

Note to the following, and install in the reverse order of removal.

Fuel Level Sensor Unit

1.

Install new seal packing to fuel tank without any twist.

2.

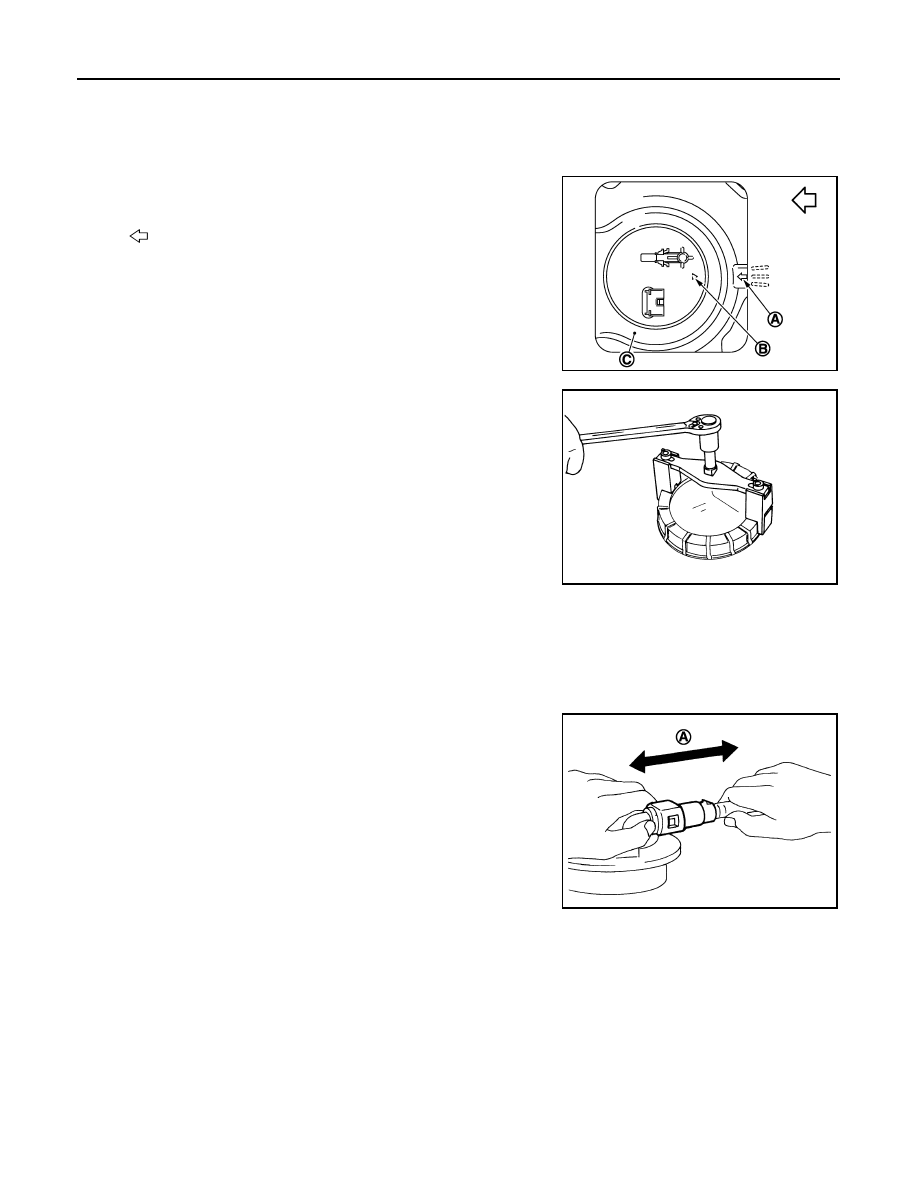

Align (B) with (A) as shown in the figure. Install fuel level sensor

unit, fuel filter and fuel pump assembly to fuel tank (C).

CAUTION:

• Never allow seal packing to drop.

• Never bend float arm during installing.

3.

Install seal packing for fuel level sensor unit, fuel filter and fuel

pump assembly with lock ring wrench (commercial service tool)

by turning clockwise.

CAUTION:

Install lock ring horizontally.

Quick Connector

Connect quick connector as follows:

1.

Check the connection for damage or any foreign materials.

2.

Align the connector with the tube, then insert the connector straight into the tube until a click sound is

heard.

3.

After connecting, check that the connection is secure by following method.

• Pull the tube and the connector to check they are securely

connected.

• Visually confirm that the two retainer tabs are connected to the

connector.

Inspection

INFOID:0000000003793253

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leakage.

1.

Turn ignition switch “ON” (with engine stopped), then check connections for leakage by applying fuel pres-

sure to fuel piping.

2.

Start engine and let it idle and check there are no fuel leakage at the fuel system connections.

: Vehicle front

PBIC4584J

PBIC0240E

A

: Pull

JPBIA0140ZZ