Nissan Teana J32. Manual - part 557

EXL-198

< BASIC INSPECTION >

[HALOGEN TYPE]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

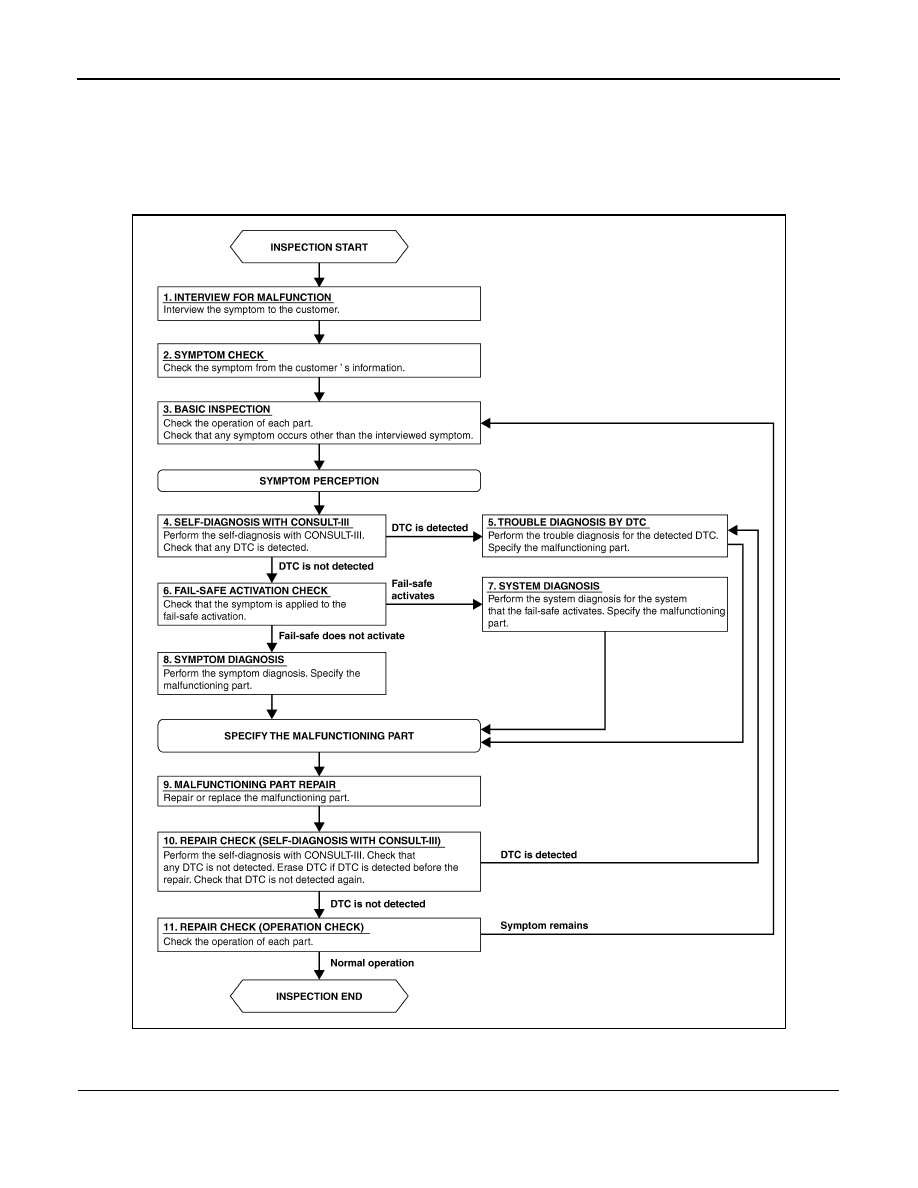

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

INFOID:0000000003773646

OVERALL SEQUENCE

DETAILED FLOW

1.

INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer.

JPLIA0313GB