Nissan Teana J32. Manual - part 280

CHG

ALTERNATOR

CHG-21

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

ON-VEHICLE REPAIR

ALTERNATOR

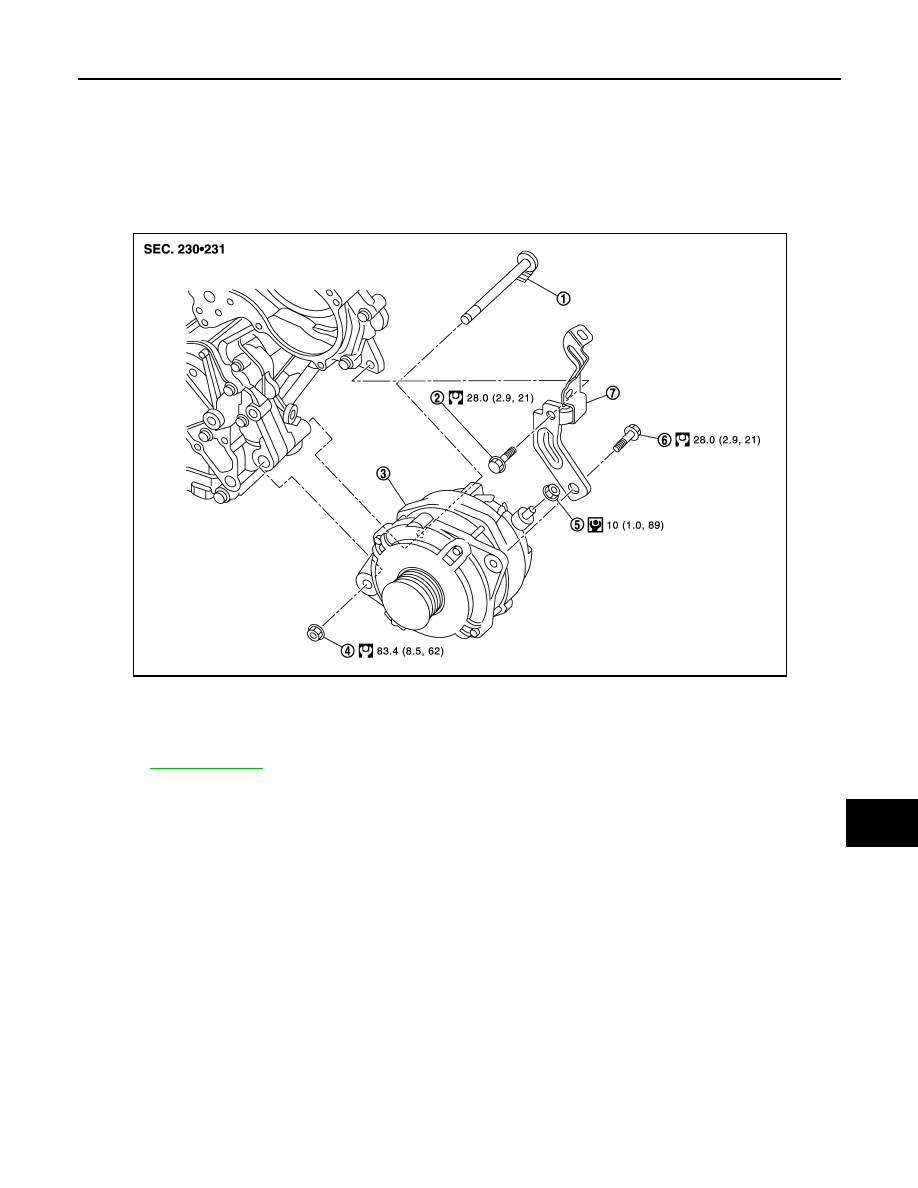

Exploded View

INFOID:0000000003860538

REMOVAL

DISASSEMBLY

1.

Alternator mounting bolt

2.

Alternator stay mounting bolt

3.

Alternator

4.

Alternator mounting nut

5.

“B” terminal nut

6.

Alternator stay mounting bolt

7.

Alternator bracket

Refer to

JPMIA1133GB