содержание .. 605 606 607 608 ..

Nissan Murano Z51. Manual - part 607

EC-436

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

ELECTRONIC CONTROLLED ENGINE MOUNT

Check the following.

• Harness connectors E6, F123

• 10 A fuse (No. 3)

• Fuse block (J/B) connector E103

• Harness for open or short between electronic controlled engine mount control solenoid valve and fuse

>> Repair open circuit, short to ground or short to power in harness or connectors.

5.

CHECK ELECTRONIC CONTROLLED ENGINE MOUNT CONTROL SOLENOID VALVE OUTPUT SIG-

NAL CIRCUIT FOR OPEN AND SHORT

1.

Disconnect ECM harness connector.

2.

Check the continuity between ECM harness connector and electronic controlled engine mount control

solenoid valve harness connector.

3.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair open circuit, short to ground or short to power in harness connectors.

6.

CHECK ELECTRONIC CONTROLLED ENGINE MOUNT CONTROL SOLENOID VALVE

EC-436, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Replace electronic controlled engine mount control solenoid valve.

7.

CHECK ELECTRONIC CONTROLLED ENGINE MOUNT

1.

Turn ignition switch OFF.

2.

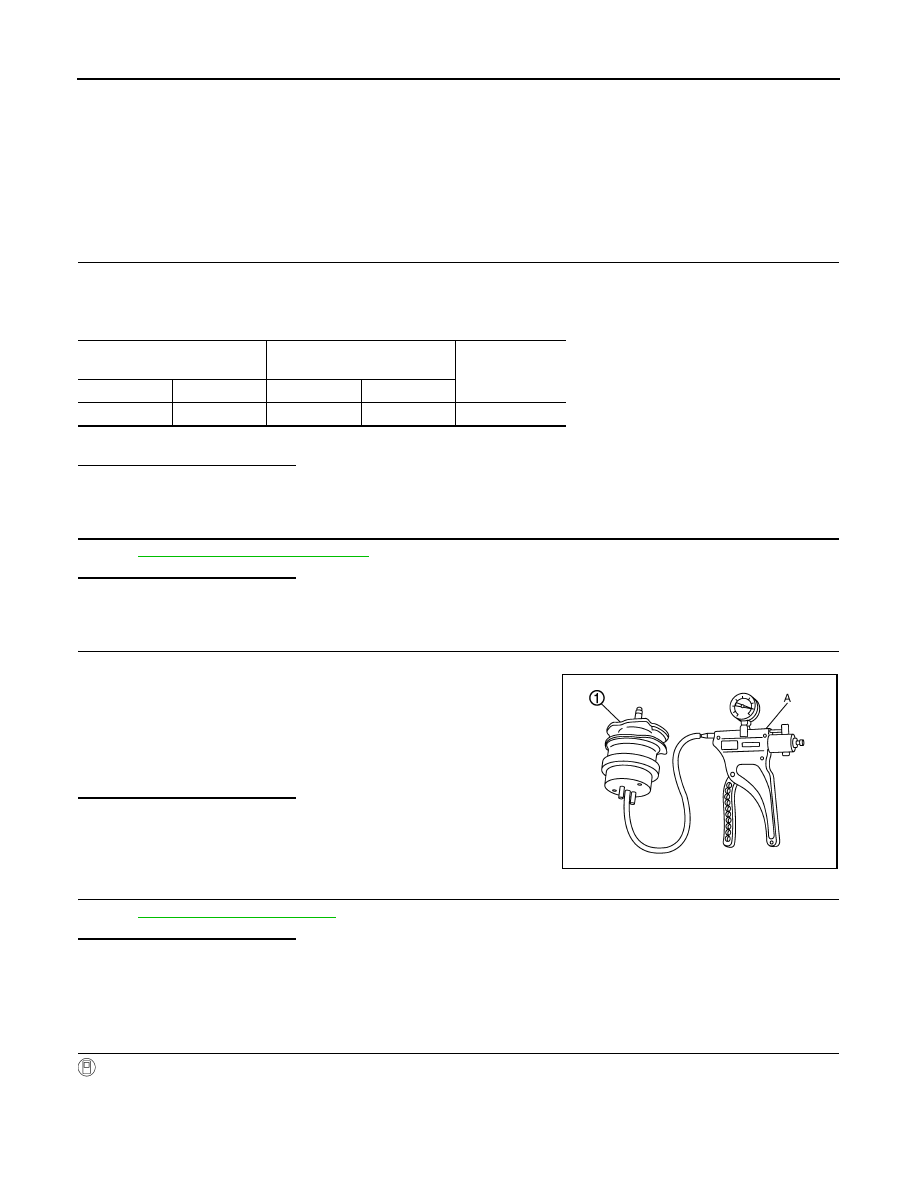

Install vacuum pump (A) to electronic controlled engine mount

(1).

3.

Check that a vacuum is maintained when applying the vacuum

of -40 kPa (-0.41 kg/cm

2

, -5.8 psi) to electronic controlled engine

mount.

4.

Also visually check electronic controlled engine mount.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Replace electronic controlled engine mount.

8.

CHECK INTERMITTENT INCIDENT

GI-39, "Intermittent Incident"

Is the inspection result normal?

YES

>> Replace intake manifold collector.

NO

>> Repair or replace malfunctioning part.

Component Inspection

INFOID:0000000005536868

1.

CHECK ELECTRONIC CONTROLLED ENGINE MOUNT CONTROL SOLENOID VALVE

With CONSULT-III

1.

Turn ignition switch OFF.

2.

Reconnect electronic controlled engine mount control solenoid valve harness connector.

3.

Disconnect vacuum hoses connected to electronic controlled engine mount control solenoid valve.

4.

Turn ignition switch ON.

ECM

Electronic controlled engine

mount control solenoid valve

Continuity

Connector

Terminal

Connector

Terminal

F7

28

F11

2

Existed

MBIB1237E