содержание .. 606 607 608 609 ..

Nissan Murano Z51. Manual - part 608

EC-440

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

FUEL INJECTOR

Component Inspection

INFOID:0000000005536872

1.

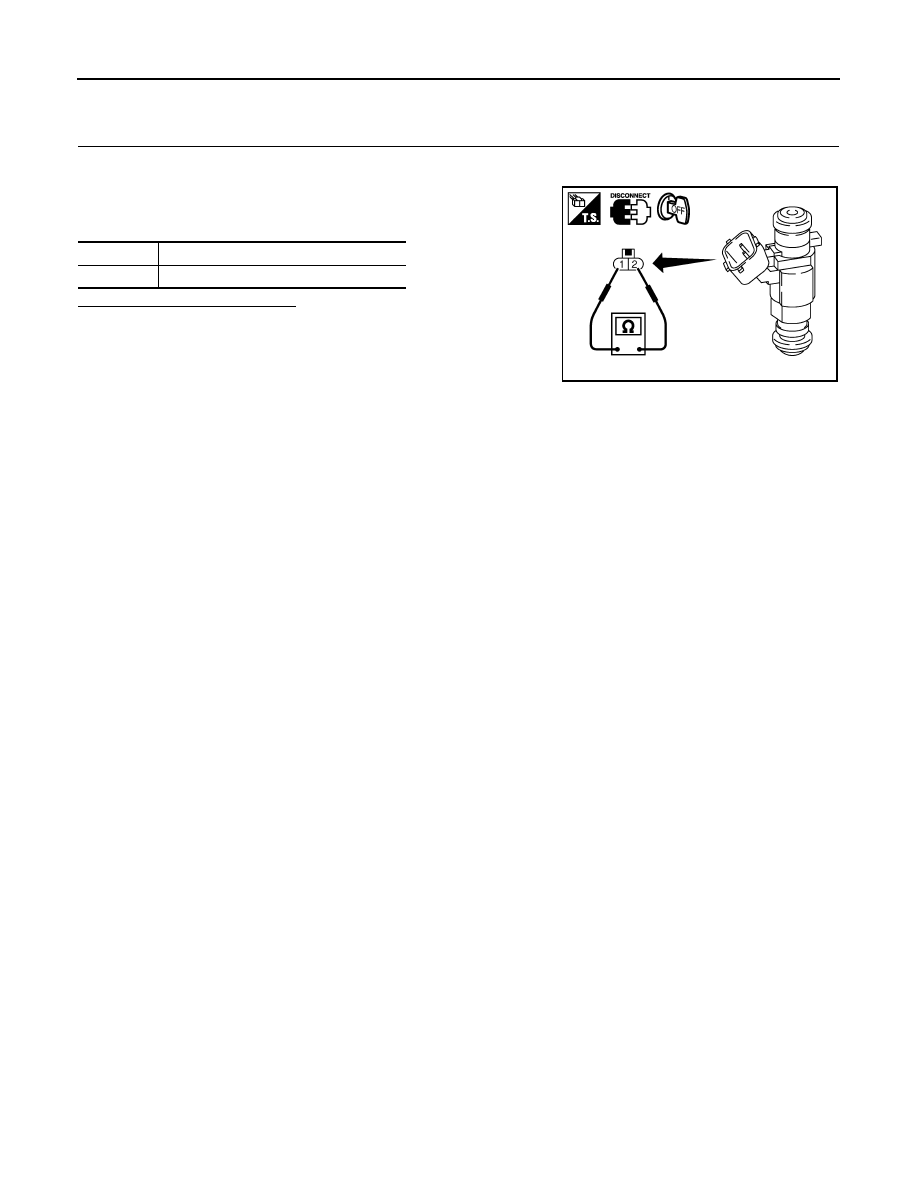

CHECK FUEL INJECTOR

1.

Turn ignition switch OFF.

2.

Disconnect fuel injector harness connector.

3.

Check resistance between fuel injector terminals as per the fol-

lowing.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace malfunctioning fuel injector.

Terminals

Resistance

1 and 2

11.1 - 14.5

Ω

[at 10 - 60

°

C (50 - 140

°

F)]

PBIB1727E