содержание .. 494 495 496 497 ..

Nissan Murano Z51. Manual - part 496

DLN-118

< UNIT DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

DRIVE PINION

Assembly

INFOID:0000000005514271

1.

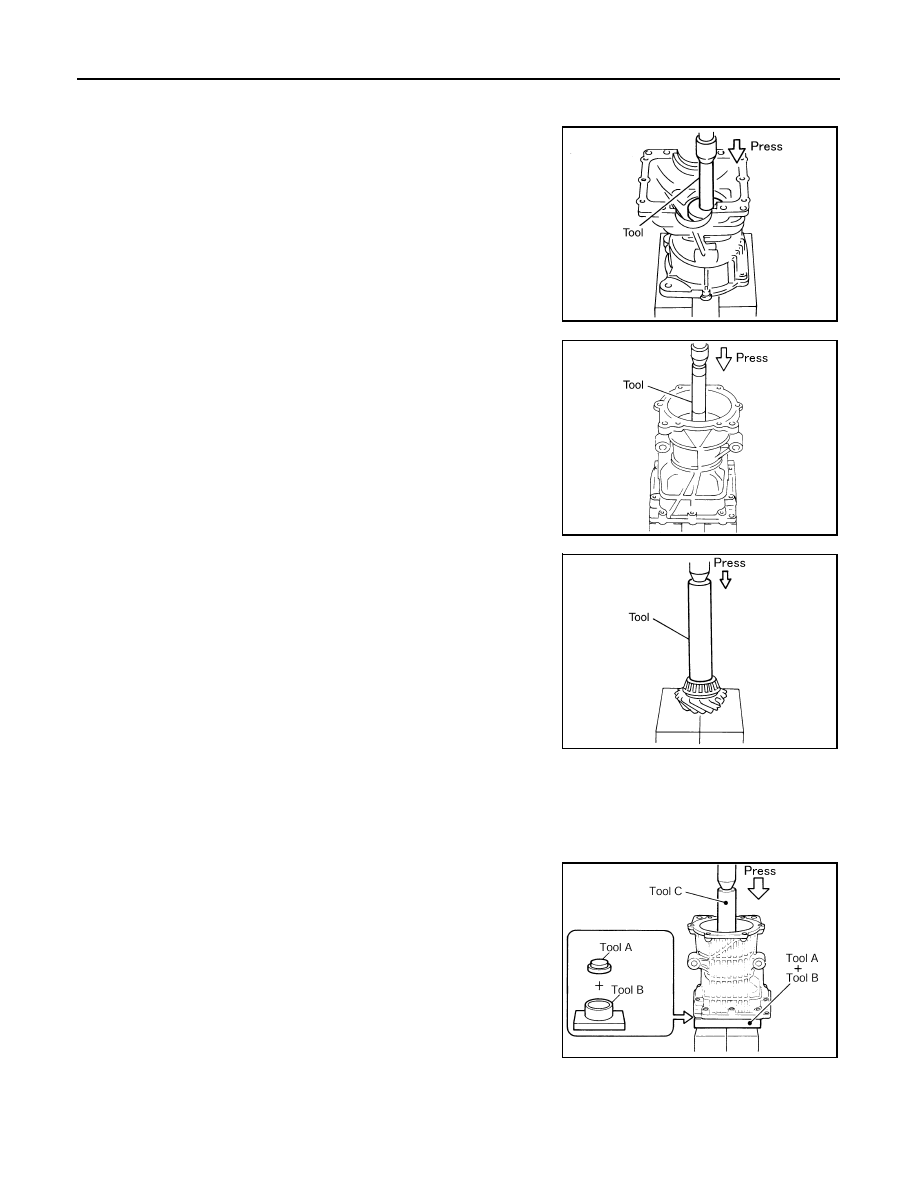

Install a drive pinion adjusting shim of the same thickness as

was installed prior to disassembly. Press pinion rear bearing

outer race into gear carrier, using the drift [SST: ST1713000

(

—

).

CAUTION:

• At first, using a hammer, tap bearing outer race until it

becomes flush to gear carrier.

• Never reuse pinion rear bearing outer race.

2.

Press pinion front bearing outer race into gear carrier, using the

drift [SST: 33230000 (J-25805-01)].

CAUTION:

• At first, using a hammer, tap bearing outer race until it

becomes flush to gear carrier.

• Never reuse pinion front bearing outer race.

3.

Press pinion rear bearing inner race to drive pinion, using the

drift [SST: ST23860000 (

—

)].

CAUTION:

Never reuse pinion rear bearing inner race.

4.

After checking and adjusting the tooth contact and backlash of the drive gear and drive pinion following

the procedure below.

a.

Apply gear oil to the pinion rear bearing, and assemble the drive pinion to the gear carrier.

CAUTION:

Never assemble a collapsible spacer.

b.

Apply gear oil to pinion front bearing, and assemble pinion front

bearing inner race to drive pinion. Using the drifts and stand,

press pinion front bearing inner race to drive pinion as far as

drive pinion nut can be tightened.

CAUTION:

Never reuse pinion front bearing inner race.

c.

Temporarily tighten removed drive pinion nut to drive pinion.

NOTE:

Use removed drive pinion nut only for the preload measurement.

PDIA0056E

PDIA0067E

PDIA0068E

A

: Drift [SST: KV40100610 (J-26089)]

B

: Drift [SST: ST38220000 (

—

)]

C

: Drift [SST: ST23860000 (

—

)]

PDIA0057E