содержание .. 493 494 495 496 ..

Nissan Murano Z51. Manual - part 495

DLN-114

< UNIT DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

DIFFERENTIAL ASSEMBLY

12. Install dummy cover set, check and adjust drive gear runout, tooth contact, backlash, and total preload

13. Remove dummy cover set.

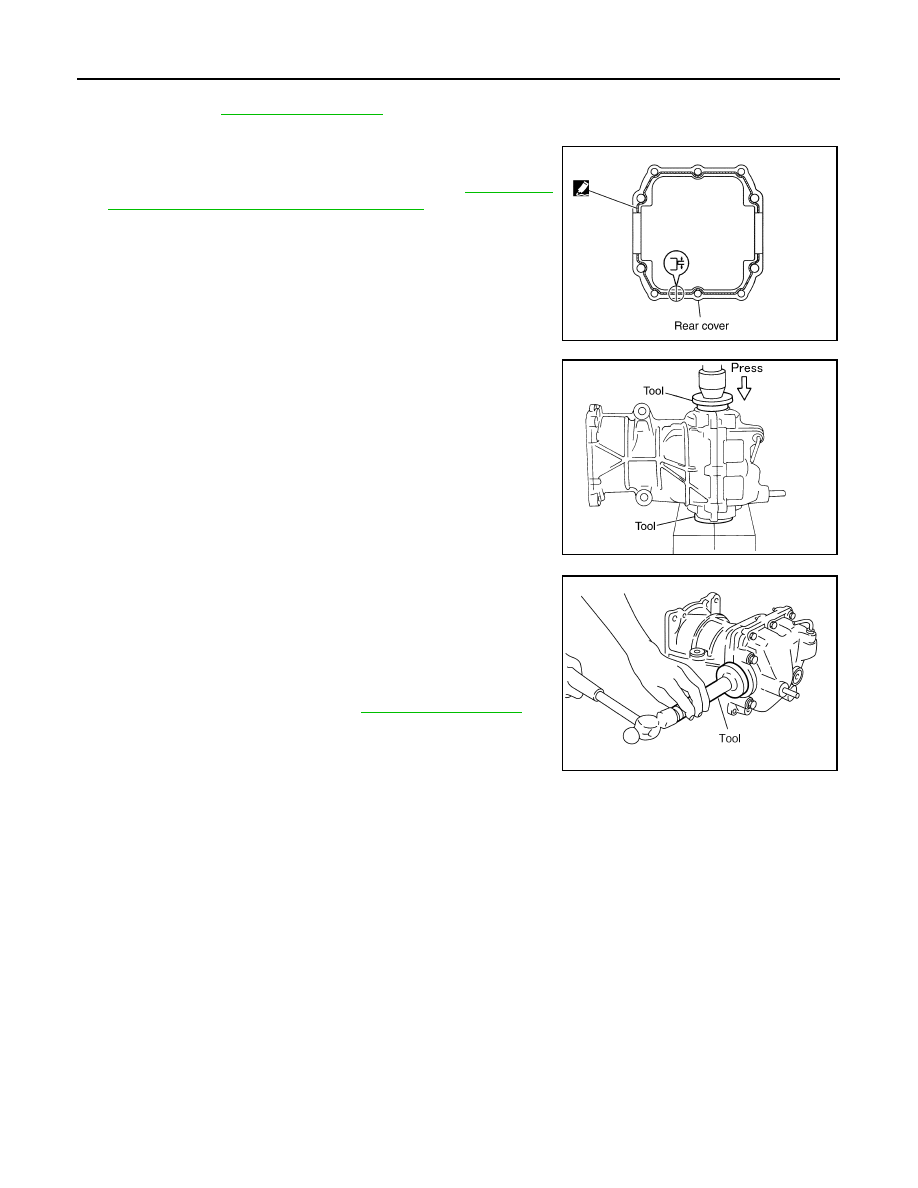

14. Apply liquid gasket to mating surface of rear cover. Overlap both

ends of the bead for at least 3 mm (0.12 in).

Use Genuine Silicone RTV or equivalent. Refer to

ommended Chemical Products and Sealants"

CAUTION:

Remove old gasket adhering to the mounting surfaces.

Also remove any moisture, oil, or foreign material adhering

to the mounting surfaces.

15. Set the drifts [SST: KV40100610 (J-26089)] to the right and left

side bearing adjusting shims individually. Compress differential

case assembly and side bearing to install rear cover.

CAUTION:

• The drift shall be placed on the center of the adjusting

shims.

• The pressure shall be as low as possible to install the rear

cover. The maximum pressure shall be 10 kN (1 ton, 1.0

Imp ton).

• If rear cover is forced in by tapping, rear cover may be

damaged by adjusting shims. Avoid tapping.

16. Tighten rear cover mounting bolts to the specified torque.

17. Using the drift [SST: KV38100200 (J-26233)], drive side oil seals

until it becomes flush with the carrier end.

CAUTION:

• Never reuse oil seals.

• When installing, do not incline oil seals.

• Apply multi-purpose grease onto oil seal lips, and gear oil

onto the circumference of oil seal.

18. Check total preload torque. Refer to

.

Inspection After Disassembly

INFOID:0000000005514268

DRIVE GEAR AND DRIVE PINION

• Clean up the disassembled parts.

• If the gear teeth never mesh or line-up correctly, determine the cause and adjust or replace as necessary.

• If the gears are worn, cracked, damaged, pitted or chipped (by friction) noticeably, replace with new drive

gear and drive pinion as a set.

BEARING

• Clean up the disassembled parts.

• If any chipped (by friction), pitted, worn, rusted or scratched marks, or unusual noise from the bearing is

observed, replace as a bearing assembly (as a new set).

SIDE GEAR AND PINION MATE GEAR

• Clean up the disassembled parts.

• If any cracks or damage on the surface of the tooth is found, replace.

• If any worn or chipped mark on the contact sides of the thrust washer is found, replace.

SIDE GEAR THRUST WASHER AND PINION MATE THRUST WASHER

• Clean up the disassembled parts.

• If it is chipped (by friction), damaged, or unusually worn, replace.

PDIA0447E

PDIA0065E

PDIA0448E