содержание .. 491 492 493 494 ..

Nissan Murano Z51. Manual - part 493

DLN-106

< UNIT DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

ELECTRIC CONTROLLED COUPLING

3.

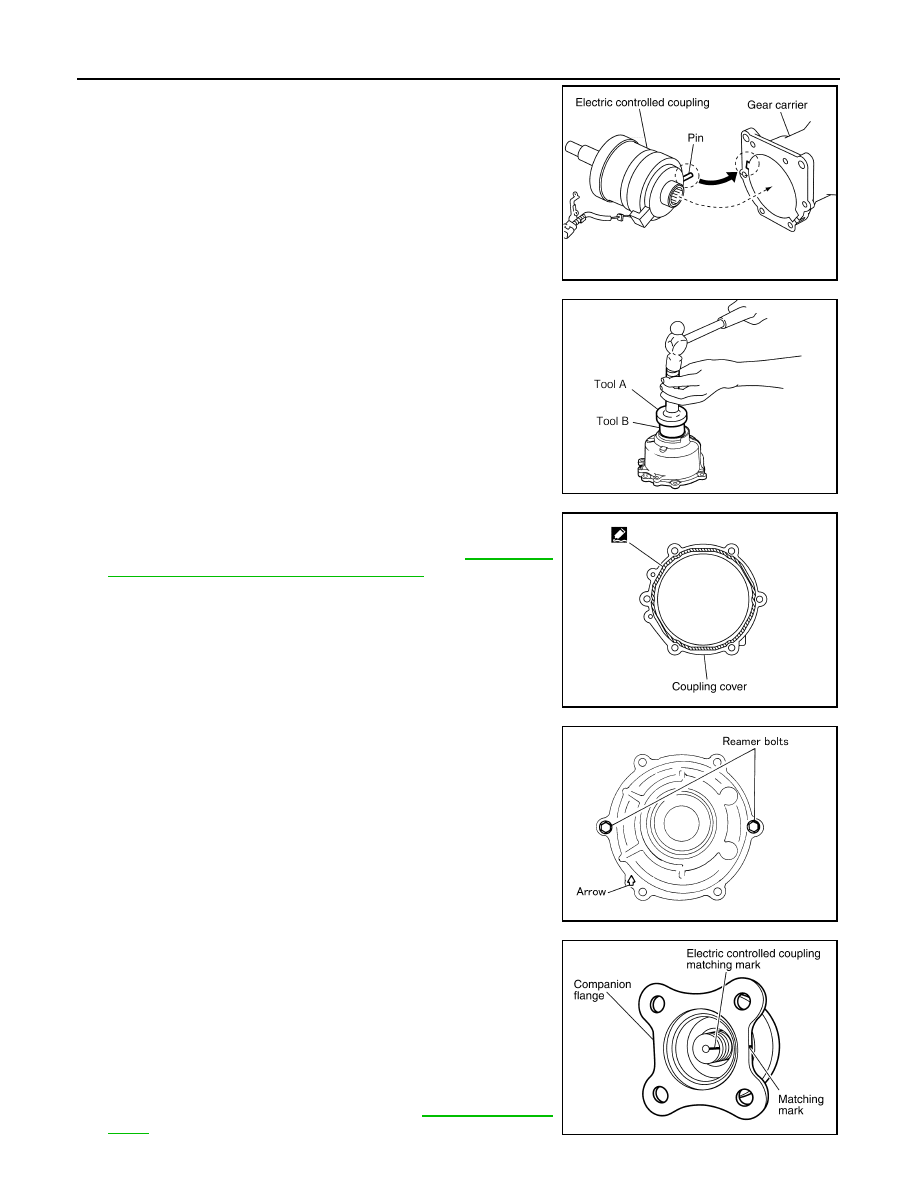

Install electric controlled coupling to spline of drive pinion inside

gear carrier.

CAUTION:

• Align the pin on electric controlled coupling with the

groove of gear carrier.

• Be careful not to damage center oil seal.

4.

Set AWD solenoid harness guide to gear carrier.

5.

Using the drifts, drive front oil seal until it becomes flush with the

coupling cover end.

CAUTION:

• Never reuse oil seal.

• When installing, never incline oil seal.

• Apply multi-purpose grease onto oil seal lips, and gear oil

onto the circumference of oil seal.

6.

Apply liquid gasket to mating surface of coupling cover. Overlap

both ends of the bead for at least 3 mm (0.12 in).

Use Genuine Silicone RTV or equivalent. Refer to

ommended Chemical Products and Sealants"

CAUTION:

Remove old gasket adhering to the mounting surfaces.

Also remove any moisture, oil, or foreign material adhering

to the mounting surfaces.

7.

Install coupling cover to gear carrier with arrow facing upward,

temporarily tighten reamer bolts to the positions shown in the

figure.

8.

Tighten reamer bolts and coupling cover mounting bolts to the

specified torque.

9.

Install connector bracket, and tighten bolts to the specified

torque.

10. Install companion flange.

NOTE:

When reusing electric controlled coupling, align the matching

mark of electric controlled coupling with the matching mark of

companion flange, then install companion flange.

11. Install companion flange lock nut with flange wrench (commer-

cial service tool), tighten to the specified torque.

CAUTION:

Never reuse companion flange lock nut.

12. Check companion flange runout. Refer to

PDIA0463E

A

: Drift [SST: KV38100200 (J-26233)]

B

: Drift [SST: ST27861000 (

—

)]

PDIA0449E

PDIA0613E

SDIA0587E

PDIA0455E