содержание .. 1007 1008 1009 1010 ..

Nissan Murano Z51. Manual - part 1009

CHASSIS MAINTENANCE

MA-31

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

Never reuse gasket.

REAR PROPELLER SHAFT

REAR PROPELLER SHAFT : Inspection

INFOID:0000000005516165

NOISE

• Check the propeller shaft tube surface for dents or cracks. If damaged, replace propeller shaft assembly.

• If center bearing is noisy or damaged, replace propeller shaft assembly.

VIBRATION

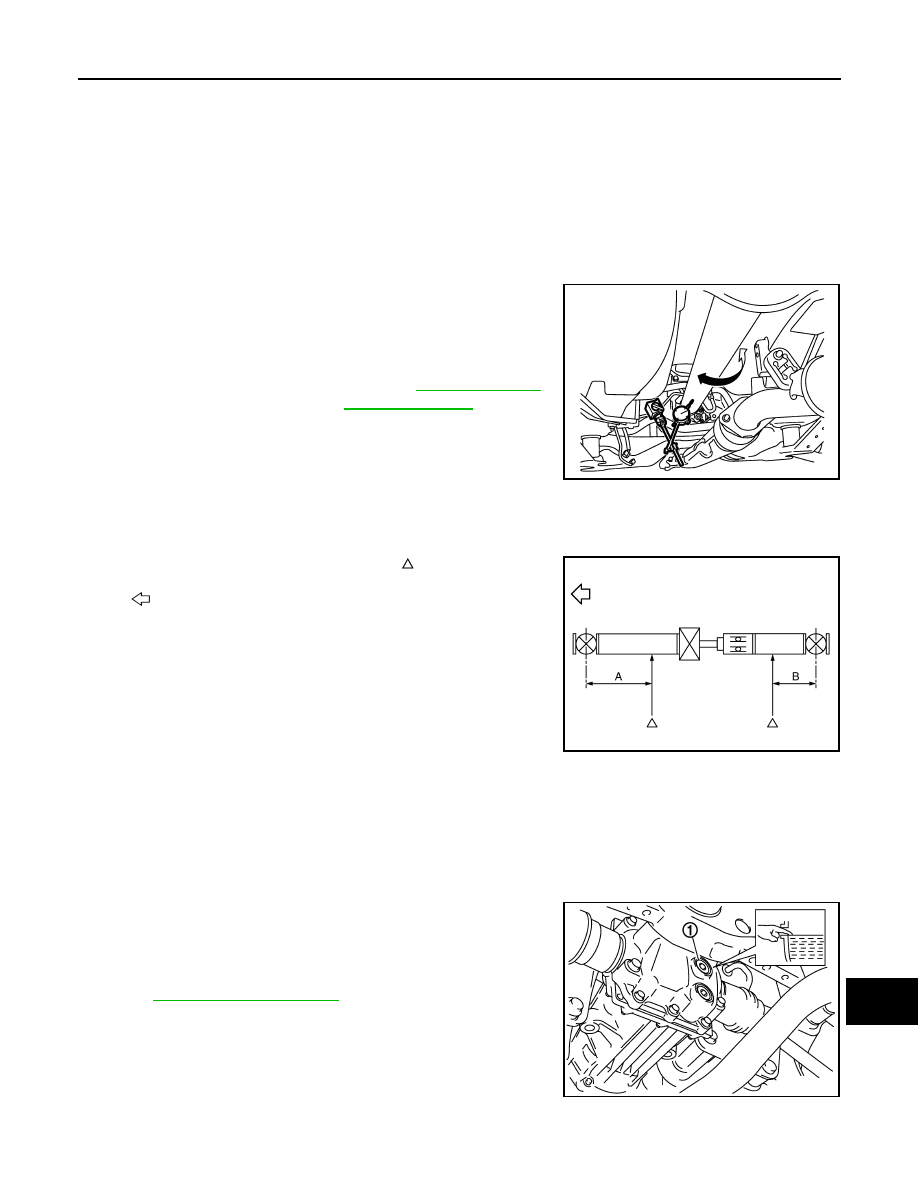

If vibration is present at high speed, inspect propeller shaft runout first.

1.

With a dial indicator, measure propeller shaft runout at runout

measuring points by rotating final drive companion flange with

hands.

2.

If runout still exceeds specifications, separate propeller shaft at

final drive companion flange or transfer companion flange; then

rotate companion flange 90, 180, 270 degrees and install pro-

peller shaft.

3.

Check runout again. If runout still exceeds specifications, replace propeller shaft assembly.

4.

Check the vibration by driving vehicle.

RUNOUT MEASURING POINT

Propeller shaft runout measuring point (Point “ ”).

REAR DIFFERENTIAL GEAR OIL

REAR DIFFERENTIAL GEAR OIL : Inspection

INFOID:0000000005516166

OIL LEAKAGE

Check that oil is not leaking from final drive assembly or around it.

OIL LEVEL

• Remove filler plug (1) and check oil level from filler plug mounting

hole as shown in the figure.

CAUTION:

Never start engine while checking oil level.

• Set a new gasket on filler plug and install it on final drive assembly.

.

CAUTION:

Never reuse gasket.

Limit

Propeller shaft runout

: Refer to

.

JPDID0172ZZ

: Vehicle front

Dimension

A: 506.5 mm (19.94 in)

B: 497.5 mm (19.59 in)

JPDID0156ZZ

JPDID0164ZZ