содержание .. 1005 1006 1007 1008 ..

Nissan Murano Z51. Manual - part 1007

ENGINE MAINTENANCE

MA-23

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

FUEL LINES : Inspection

INFOID:0000000005516149

Inspect fuel lines, fuel filler cap, and fuel tank for improper attach-

ment, leakage, cracks, damage, loose connections, chafing or dete-

rioration.

If necessary, repair or replace damaged parts.

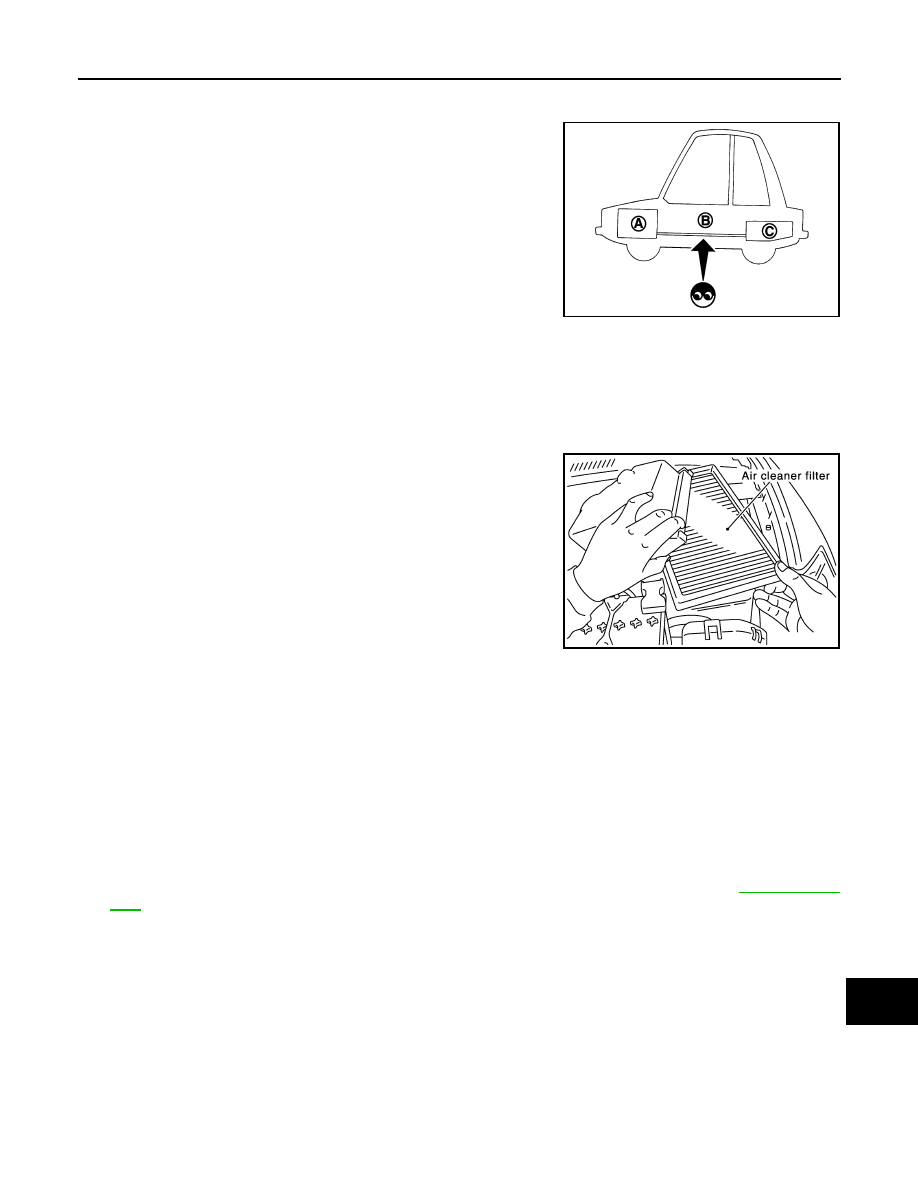

AIR CLEANER FILTER

AIR CLEANER FILTER : Removal and Installation

INFOID:0000000005516150

REMOVAL

1.

Unhook air cleaner case (lower) side clips and lift up air cleaner case (upper).

2.

Remove air cleaner filter and holder assembly from air cleaner

case (lower).

3.

Remove the air cleaner filter from the holder.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Install the air cleaner filter by aligning the seal with the notch of air cleaner case.

ENGINE OIL

ENGINE OIL : Draining

INFOID:0000000005516151

WARNING:

• Be careful not to get burn yourself, as engine oil may be hot.

• Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1.

Warm up the engine, and check for engine oil leakage from engine components. Refer to

2.

Stop the engine and wait for 10 minutes.

3.

Loosen oil filler cap.

A

: Engine

B

: Fuel line

C

: Fuel tank

JPBIA0129ZZ

PBIC1165E